How to choose a window sealant?

A large amount of heat escapes from the room through the windows. To reduce this factor, sealants are used that are intended specifically for window structures. There are many of them on the market, there are many differences between them. So that the result does not disappoint, you need to know about the rules for their selection and own some subtleties.

Peculiarities

Window sealant is a plastic mass containing polymers. After application to the surface, the mass gradually hardens. The result is a layer that acts as a barrier to air and moisture penetration. The application of sealant allows you to get rid of drafts, increase the tightness of the structure and its ability to retain heat.

Window putties are produced in special containers that differ in volume. The compositions of the various sealants differ significantly, but one component remains unchanged - the solvent. When applied to a work surface, the material begins to harden quickly.

Views

Window sealant comes in many varieties. It will be very difficult for an ignorant person to understand this assortment. Thanks to this review, the problem of choice is greatly facilitated, everyone will be able to determine which option will be better for a specific task.

Silicone material is considered versatileas it can be used indoors and outdoors. It contains organic compounds based on silicon. These options are flexible, easy to apply and have good adhesive properties. They are also inexpensive.

Silicone sealants are available in several varieties. Acidic varieties have an unpleasant vinegar odor that evaporates quickly. For interior work, a sanitary look is more suitable. It has a white color and is immune to the formation of fungi.

The composition may contain various components, which determines the scope of use and features of the purpose of the sealant. The main varieties include antiseptic, which are used in high humidity, heat-resistant, intended for hot surfaces, neutral and acidic.

The latter option is intended for plastic; it is strictly forbidden to apply it to metal.

Silicone sealants, in turn, are divided into three groups:

- universal acidic putties are called construction ones, they are inexpensive, but they also cannot boast of high quality;

- versatile neutral materials are often chosen for plastics, concrete, stone and mirrored surfaces;

- sanitary sealants contain antifungal components, therefore they are recommended for use in rooms with high humidity.

Acrylic sealant is often used for plastic windows. Its characteristics and features are not inferior to the silicone-based competitor. The acrylic material can be easily removed from the surface until it hardens, resistant to ultraviolet radiation and weather conditions. This putty is capable of absorbing vapors, which leads to darkening. Since the material is vapor-permeable, it is not recommended to use it for interior work.

Polymeric material is also called liquid plastic. It hardens quickly and adheres perfectly to surfaces, forming a single whole with them. But from loads it can burst, which is a significant drawback.The polymer is expensive due to its high technological characteristics.

Polyurethane putty attracts the user with high elasticity, waterproofness and the ability to maintain its shape regardless of external factors, including weather conditions. On top, you can apply a layer of paint or varnish. This material is frost-resistant, therefore it can be used outdoors. But it is undesirable to work with it indoors, since the sealant is not safe for humans. Able to bind various materials: concrete, metal, plastic. The durability of the sealant reaches 25 years, this indicator is not influenced by atmospheric phenomena and harsh operating conditions.

Butyl is created on the basis of rubber, withstands temperatures from -55 to +100. It contains no harmful substances, it is elastic and durable, not afraid of the sun and precipitation. Not only the seams are treated with butyl sealant, but even repair work is carried out with double-glazed windows, since this is a vapor barrier material.

Bituminous materials can only be used from the outside of the building. For interior work, such sealants are contraindicated. They are used for drainage, roofing, repair of foundations. These putties are flexible and completely waterproof and can be applied to uncleaned joints without any preparation.

The combination of polyurethane and silicone in one sealant is a new kind of material. Such putties are called MC-polymer, they are created from siliconized polyurethane. The cost of the novelty is considerable, but the performance characteristics are also very high. The seams are durable, strong and resilient and can be painted and repaired.

Thiokol sealant is created on the basis of polysulfide substances. Curing is carried out at any temperature and conditions. For outdoor work, there is no better option. Both in frost and heat, it will perform its functions in full.

Stiz A is a popular material that is often chosen for sealing windows from the outside. It is also used in the installation of window structures. It adheres equally well to all building materials. For interior work, "Stiz V" is used.

Cork sealant - another novelty, which in a short period of its existence has won the favor of consumers. This putty contains cork chips, which in some cases can be up to 90% of the total volume. The scope of application is huge: thermal protection systems, sealing of building structures, installation of floor coverings, filling installation seams, increasing sound insulation. Cork sealant is available in different volumes, may differ in composition and color.

Scope of application

Sealants have already become indispensable in many industries. Even in the home kit of tools and materials, the sealant is a must.

Such materials have a wide range of applications:

- protection of PVC seams and openings from atmospheric agents;

- connection of frames and glasses to each other;

- insulation of window blocks;

- filling voids and fixing window sills during their installation;

- filling external / internal cracks / joints between the wall and the window structure when installing and resealing wooden, aluminum and plastic boxes;

- sealing joints in concrete, reinforced concrete structures outside and inside with a deformation of no more than 25%;

- prevention of drafts for the winter;

- glazing of balconies;

- installation / repair of roofs, vertical windows, attics and other construction projects;

- filling gaps between a wall or facade;

- installation of ventilated facades.

Sealants are actively used in warehouses, in construction, in the production of window systems, during the installation process, room insulation and in many other situations.

How to use?

Sealing may well be done on your own.Turning to workers is an unnecessary and unreasonable waste. With the instructions, this work can be done in no time. We will assume that the slopes have already been made earlier, therefore we will not dwell on this issue.

The algorithm for sealing work will be as follows:

- The first point will be the preparation of tools and consumables. In the process, you will need a syringe for applying sealant, a container of water and construction tape.

- The slopes need to be prepared for further work. The essence of the preparation is to stick construction tape, which will protect the window structure from dirt and save us time.

- The working area must be carefully cleaned. There should be no dirt or even dust. It is also necessary to remove the protective film down to the slightest fragment. For degreasing plastic structures, it is forbidden to use solvents containing acetone. With this treatment, cloudy, matte stains, stains that differ in color and other troubles may appear on the surface.

- Using a construction syringe, slowly squeeze the sealant into the seam area. The tool should be angled so that the tip flattens the material to be applied.

- The remaining irregularities and other defects are smoothed out with a finger previously soaked in water. This trick will prevent material from sticking and provide a smooth finish. Seams need to be well filled with putty so that there are no voids.

- From surfaces it is necessary to remove the remnants of the material even before it hardens. In this case, it is convenient to use a damp sponge. You need to act very carefully so as not to violate the integrity of the sealant applied to the seams.

- You don't need to put putty on all seams at once. Better to work in stages. In this case, it will be possible to avoid hardening of the material until it is flattened and the residues are removed.

Manufacturers

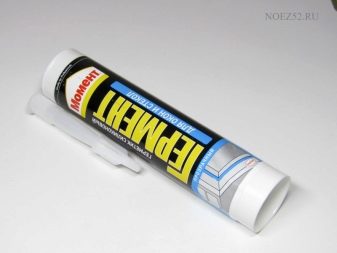

Brand Sealants "Moment" are available in a wide variety. You can choose the option you want for a specific task. There is also a universal putty on sale, which is popular and allows you to solve problems of various kinds. Moment products are attractive for their high quality, which allows them to maintain their leadership position.

Putty "Steez" Is the choice of professionals. They put their trust in these sealants because they are a high quality, reliable product that does not fail and always performs its functions. A sealing substance is produced in different containers and in different volumes.

Company Bauset produces a large number of products for window systems, including sealants. Many neutral putties are produced under this brand, many of which are universal. The quality of the products is at a high level, the cost is affordable, the preservation of operational characteristics is long-term.

Under the brand name "Vilatherm" a sealing harness is produced, which is widely used for sealing seams. In combination with a sealant, the tourniquet allows you to achieve an excellent result, protect the room from noise from the street, prevent moisture and cold penetration.

Tytan Professional - is a wide range of sealants, in which there are options for solving many problems of the construction and repair plan. You can choose a versatile putty that will help you tackle a number of minor household problems. Also, it will not be difficult to choose a special option for solving a specific goal. The cost of Tytan Professional products is in the middle segment, but the quality corresponds to the premium level.

Companies Isocork and Bostik release the cork sealant that was mentioned in this conversation. There are other manufacturers, but these are the two that produce the most worthy products.

Advice

It is worth considering a few tips to help you avoid common mistakes:

- Although sealing is a simple process, adherence to technology is an important condition for obtaining a high-quality result. It is enough to make one mistake, and the window structure will no longer be tight enough.

- The choice of polyurethane foam by workers installing the window is not always justified. The foam has the ability to expand, which can lead to a change in the geometry of the structure. The sealant cannot lead to such consequences.

- Any putty should be produced with a special narrow nozzle, which allows you to efficiently fill gaps of any size. The spot nozzle allows you to gently fill even small crevices and joints with material.

- Buying a quality putty is half the battle. You do not need to spare money to buy material from a well-known manufacturer that guarantees high quality and protects its brand from counterfeiting.

- The color of the putty should be chosen according to the object on which it will be used. For white structures, such as PVC windows, you must choose a white putty. In the case of colored objects, it is best to stick with a transparent material.

- When choosing, it is imperative to take into account the place of application of the material, temperature and other operating conditions. If the selected putty does not meet these parameters, then all efforts will go down the drain.

- When working with wide slots, it is possible, and even in some cases necessary, to reduce material consumption. Firstly, it will be possible to save money, and secondly, thick and wide seams dry out for a long time, and in the future they may peel off the surface. To achieve this goal, it is necessary to lay a sealing cord inside the slot, which is intended specifically to solve such problems.

- On the outside of the window, sealant cannot be applied around the entire perimeter, only on the side parts and joints at the location of the low tide. In other areas, the presence of sealant will eventually cause moisture accumulation in the joint foam, which will lead to a decrease in its durability and performance. In this case, the sealant is replaced with a protective vapor barrier tape or plastering work is performed.

For how to quickly seal the joints and seams of plastic windows, see the next video.

The comment was sent successfully.