Generators for a gas boiler: characteristics, selection and connection

The power supply to the heating automation is very important. In order for generators for a gas boiler to meet consumer expectations, their characteristics must be taken into account. But you will have to carefully study both the features of the choice and the nuances of the connection.

Characteristic

The need to use a generator for a gas boiler due to the fact that these heating facilities have been significantly modernized in recent years. Control electronics are used in modern gas boilers. Its functionality is not limited to the regulation of the gas supply, the option of re-ignition of an extinguished burner is supported. But "any" generator cannot be used in conjunction with a boiler. Important:

- power;

- current frequency;

- voltage and strength of electrical impulses;

- phase characteristic of the power supply.

Views

The generation of current for a gas boiler can be carried out by various types of portable power plants. Some people acquire equipment with a gasoline engine... This solution is quite inexpensive. Nevertheless, a high-power motor is hidden in a compact body, which satisfies all the needs of consumers. It hardly makes sense to use a diesel power source, unless you also need to power other powerful devices.

Gas powered generators They differ little from their liquid-fuel counterparts, and their main design nuances coincide (except for the features of the burner). However, it is worth considering that gas power plants of increased power are equipped not with traditional internal combustion engines, but with turbines.

Regarding devices of ordinary power, in fact, they turn out to be or hybrid (also designed for gasoline), or generally modified liquid fuel systems.

In any case, the use of gas to supply current to a gas boiler looks logical. Except for one exception (but more on that later when it comes to choosing a model).

It is important not only what kind of fuel is used in the boiler... To maintain the operation of the fuel automation, it is advisable to use inverter generator... Yes, it will be more expensive than a "simple" device, and several times. However, delivering a stable current is worth it. There is no need to worry that thin electronics will fail when there is a power surge.

A household appliance of any kind, including a gas boiler, must be powered by a pure sinusoidal current. It is about the specific nature of the waveform displayed on the graph. To determine the parameters of the pulse generated by the generator, you can use a conventional oscilloscope. If the desired sine wave is not supported, you will have to use additional converters. But it is better to immediately choose the right model and not bother with auxiliary components; and deal with synchronous and asynchronous solutions.

Choice

It should be understood that gas supply to the generator in this case is not always optimal. Of course, the possibility of using the same fuel as for the boiler itself looks attractive. But if the gas supply is organized with the help of cylinders, and there is no special pipeline and is not foreseen, this is no longer the case. You will have to spend more energy on periodic replacement of cylinders. Not to mention the increased fuel consumption and the need for additional connection.

But if you can connect the generator directly to the gas pipeline, the gas version is definitely better than the liquid fuel model:

- no need to replenish the fuel supply in the tank;

- no need to monitor how fresh gasoline is;

- the motor resource of a gas piston installation is significantly greater than that of a gasoline-powered one;

- much less carbon deposits are formed.

But the gasoline generator can be used even when the gas supply is turned off.

The next important point is distinction between synchronous and asynchronous power plants. Synchronous devices have a so-called excitation winding. The current flowing through it changes the level of magnetization, thereby affecting the output voltage. Such a power plant is ideal for a gas boiler.

It provides easy voltage regulation and responds almost instantly to load surges. The opinion that such generators have insufficient resource has long been outdated. Advanced models no longer contain collector rings, which wear out due to constant brushing. True, brushless modifications are still relatively expensive. But it is better to choose them, paying for your own peace of mind.

Have asynchronous power generators the stator is continuously magnetized. Therefore, they will not be able to provide a stable output voltage. If the load in the network changes rapidly, the voltage fluctuation will be very noticeable, and it is almost impossible to correct it. This is unacceptable for the backup power supply of heating boilers and the pumps connected to them. As soon as the output voltage drops below a certain value, the boiler will be inoperative.

Care should be taken when purchasing inverter generator systems. They make little noise under low load and consume relatively little fuel. Inside such a generator, the current is rectified, and then stabilized and at the output is again transformed into alternating current with strictly specified characteristics. But such a device will inevitably be very expensive... And if you buy a cheap inverter, additional problems may arise.

Poor quality components produce a signal that does not fully meet the optimal requirements... Until a certain moment, the boiler will smooth out these deviations, but its "safety margin" is not infinite. In addition, the motors in circulation pumps, even with a slight violation of the signal characteristics, begin to hum and overheat, consume more current. Finally, the pumps start immediately under load.

Only the most powerful inverter generators can pull it off without problems.

Connection

But even the best electric generator must be properly connected. It doesn't matter whether the power source is purchased for imported or domestic boilers - decent ventilation is essential. Moreover, it is also required for the heating equipment itself. Care must be taken to direct the exhaust gases into the main ventilation duct through a steel pipe. Experts also recommend taking care of the soundproofing of the rooms.

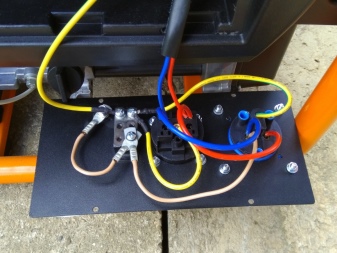

There must be at least 1 m of free space between the generator and the nearest wall - then maintenance, refueling and repairs will not cause any problems. Another indispensable requirement is grounding the device case. How to do this, it is best to find out in the instructions or in the manufacturer's technical support service. The generator interface device with the mains always implies the use of a distribution electrical panel with automatic fuses.

Do not allow the intersection of the common building and the generator network... For the latter, a copper cable must be used. The cross-section of the wire must exactly match the power of the portable power plant. Standalone connection requires to determine in advance the "zero" of the heating boiler.

Connection to a phase-dependent boiler, as its name implies, it is possible only after all phases have been determined.

The best way to do it is use a tester, diode test lamp, or indicator screwdriver. By default, the output for the emergency connection of an electric boiler (and a gas one and any other) should not break the neutral. If this is not possible, you will have to call specialists who will choose the best way to solve the problem. Important: without admission to complex electrical manipulations, such work cannot be done... The use of a generator for a wall-mounted boiler also has some subtleties.

The socket for connection (or other output) must be placed on the side of the heater. It is not advisable to place it underneath it, because it is very dangerous in case of water leakage. It is strictly forbidden to ground a wall mounted gas boiler to a pipe or radiators. You will have to connect generators through additional voltage regulator. This will further reduce operating risks.

Possible malfunctions

Sometimes difficulties arise in the work of even the most debugged systems. If the gas boiler connected to the generator stalls after a while (the burner is interrupted 3-5 seconds after starting), there is no "solid zero". All modern heating devices are equipped with gas control. This component continuously measures the ionisation current. In the absence of such a current or its excessively small value, the automation first tries to ignite the gas several times, and then blocks its flow.

Accordingly, if the boiler does not start, one of the holes of the generator output socket must be connected to the zero bus of the home wiring. But this method is not suitable for inverter devices. They will have to be connected via isolation transformer... It will also additionally smooth out sudden voltage drops. Sometimes it is necessary, however, to find out the reasons why the boiler from the gas generator does not work in any way.

Sometimes you can't even try to light a fire. In this case:

- turn the plug, checking for the presence of "zero";

- determine the voltage reached;

- trying to use a generator to power another device.

Boilers and gas water heaters work normally only at voltages from 190 to 250 V. If this is not provided by the generator itself, you will again have to use a stabilizer. But it is impossible to include it in the circuit immediately after the current source - this can provoke a "conflict". Automatic regulation of the output voltage can also distort the sine wave (this is especially typical for gasoline power plants). If simple measures do not help, it is necessary re-read instructions... If even then the problem is not solved, you should contact the professionals.

In the following view, you will learn how to properly connect the boiler to the generator.

The comment was sent successfully.