Asynchronous generator: device and principle of operation

Asynchronous generator Is a device through which it is possible to provide industrial equipment, as well as household appliances with electricity. This type of units is characterized by ease of operation and convenient design.

Device

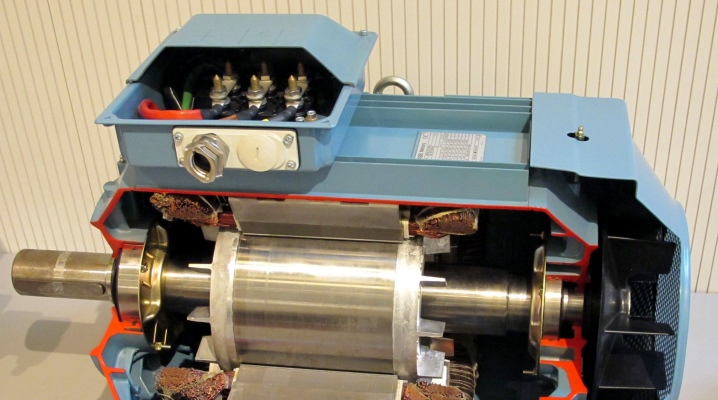

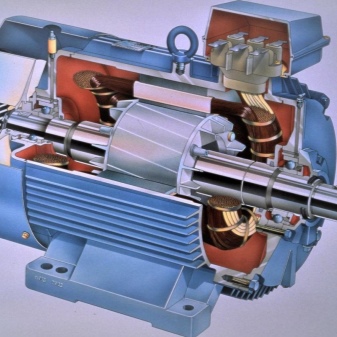

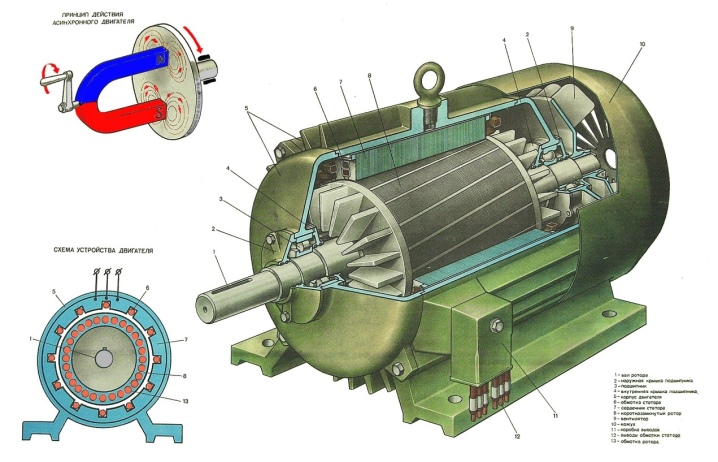

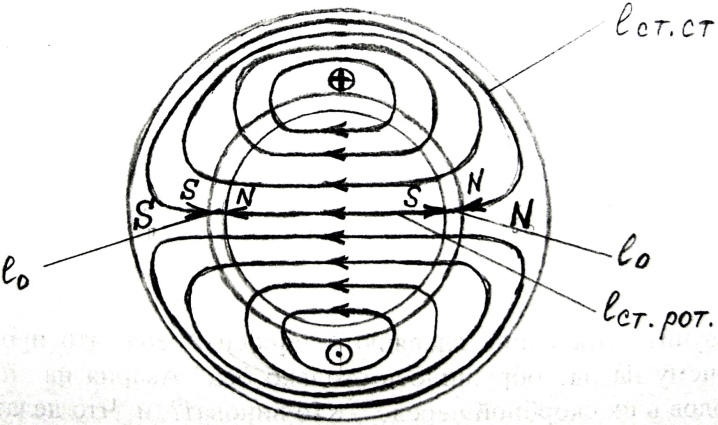

The generator has a simple structure. The main elements of the device are:

- rotor;

- stator.

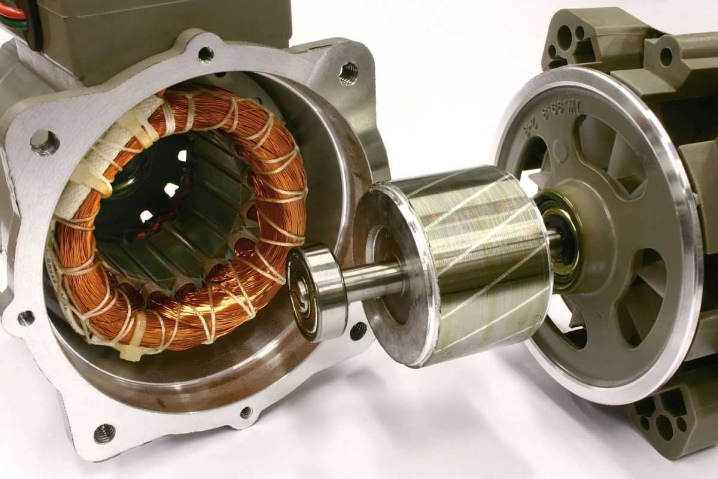

The first is a movable part, and the second element retains its position during operation. In the unit, it is not immediately possible to notice the windings of the wire, for the manufacture of which copper is usually used. However, there are windings, only they are made of aluminum rods and have improved characteristics.

The structure formed by short-circuited windings is called a squirrel cage.

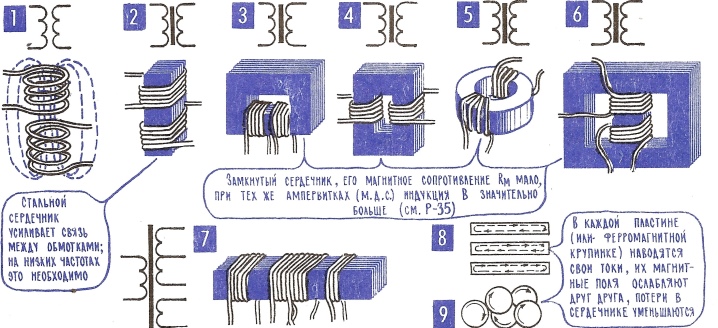

Inner space filled with steel plates, and the aluminum rods themselves are pressed into the grooves provided in the core of the movable element. The rotor is located on the generator shaft, and it itself stands on special bearings. The fixation of the unit's elements is provided by two covers that clamp the shaft on both sides. The body is made of metal material. Some models are additionally equipped with a fan for cooling the device during operation, and there are fins on the case.

The advantage of generators is the possibility of their use in a network with a voltage of both 220 V and with higher rates. For the correct connection of the unit, it is necessary to select a suitable circuit.

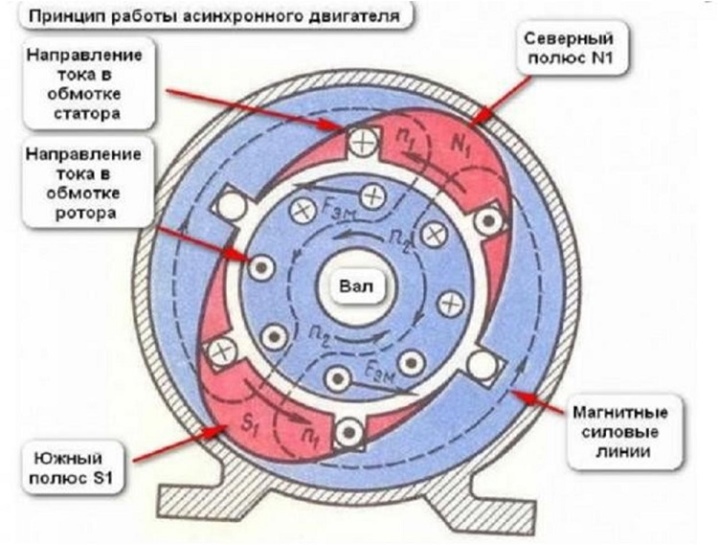

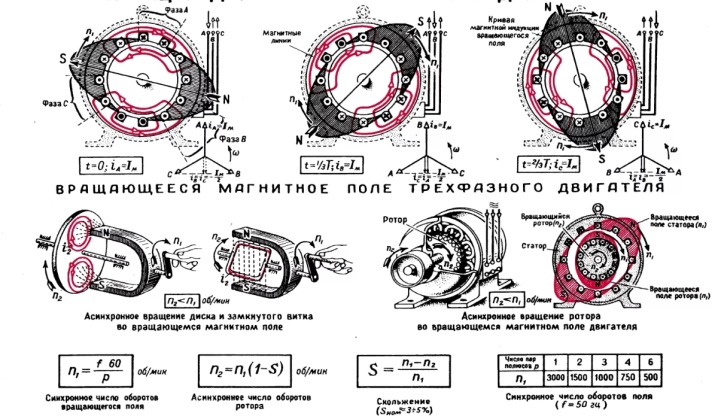

Principle of operation

The main task of the generator is to generate electrical energy by means of mechanical energy:

- wind;

- hydraulic;

- internal converted to mechanical.

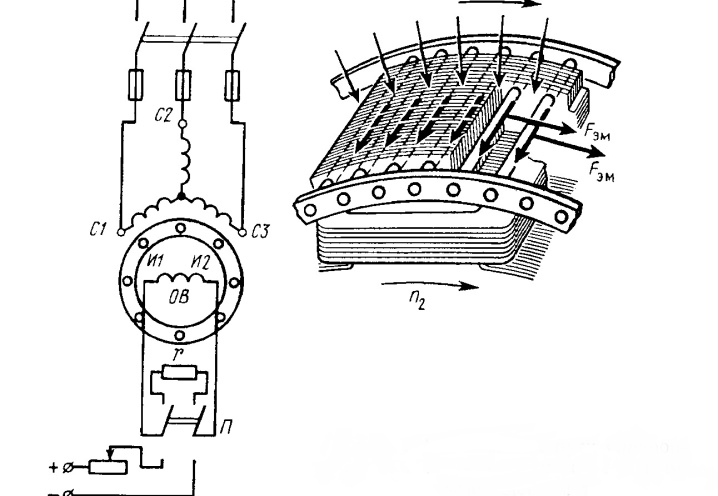

When the rotor starts to rotate, magnetic lines of force are formed in its contour. They pass through the windings provided in the stator, resulting in an electromotive force. It is she who is responsible for the appearance of current in the circuits. This happens due to the connection of active loads to the device.

An important point to consider for smooth operation is in tracking the speed of rotation of the shaft... It must be greater than the frequency at which the alternating current is generated. The last indicator is set by the stator poles. Simply put, in the process of generating electricity, it is required to ensure the frequency mismatch. They should lag behind by the amount of rotor slip.

When the shaft rotates under the influence of an external impulse obtained as a result of the use of mechanical energy, and residual magnetism, the device's own EMF arises. As a result, both fields - mobile and stationary - interact with each other dynamically.

The current obtained in the AG has small values. To increase the output power, you will need increase in magnetic induction.

Often, additional capacitor stators help to achieve this. They are connected to the terminals of the coils and the system performance is closely monitored.

Scope of application

Asynchronous generators are popular, and among the advantages of such stations are:

- resistance to overload and short circuit;

- simple design;

- a small percentage of nonlinear distortion;

- stable performance due to the low value of the clear factor;

- output voltage stabilization.

When connected, the generator emits a small amount reactive heat, therefore, its design does not require the installation of additional cooling devices. This makes it possible to reliably seal the internal cavity of the unit to protect it from moisture, dirt or dust.

Due to their advantages, generators are actively used as sources of electricity in the following areas and areas:

- transport;

- industrial;

- domestic;

- agricultural.

Also powerful units are found in auto repair shops. In addition, their simplified design allows the devices to be used as sources of electrical energy. Apparatuses are connected to them for welding, and also with their help they organize the supply of food to important healthcare facilities.

Through the operation of generators of this type, it is possible to build and launch wind and hydroelectric power plants in a short time.

Thus, even villages and farms remote from the central networks can provide themselves with energy.

What is the difference from synchronous?

The main difference between an asynchronous generator and a synchronous generator is the modified rotor design... In the second embodiment, the rotor uses wire windings. To organize the rotational movement of the shaft and create magnetic induction, the unit uses an autonomous power source, which is often a generator of lower power. It is placed parallel to the axis on which the rotor is located.

The advantage of a synchronous generator is the generation of clean electrical energy. In addition, the device easily synchronizes with other similar machines, and this is also a difference.

The only drawback consider the susceptibility to overload and short circuit. Additionally, it should be noted that the difference between the two types of equipment lies in price. Synchronous units are more expensive than asynchronous units.

As for the clear factor, its indicator is much lower for asynchronous units. Therefore, it can be argued that this type of device generates pure electric current without any pollution. Due to the action of such a machine, it is possible to ensure more reliable operation:

- UPS;

- chargers;

- new generation television receivers.

The start of asynchronous models is fast, however, it requires an increase in starting currents, which start the rotation of the shaft. The advantage is that in the course of work the structure experiences less reactive loads, due to which it was possible to improve the indicators of the thermal regime. In addition, the operation of asynchronous generators is more stable regardless of the speed at which the movable element rotates.

Views

There are several classifications of asynchronous generators. They may differ in the following factors.

- Rotor type - the rotating part of the structure. Today, the manufactured units of this type provide for a phase or squirrel-cage rotor in their design. The first is equipped with an inductive winding, which is an insulated wire. With its help, it is possible to create a dynamic magnetic field. The second option is a single structure that has a cylindrical shape. Inside it there are pins equipped with two locking rings.

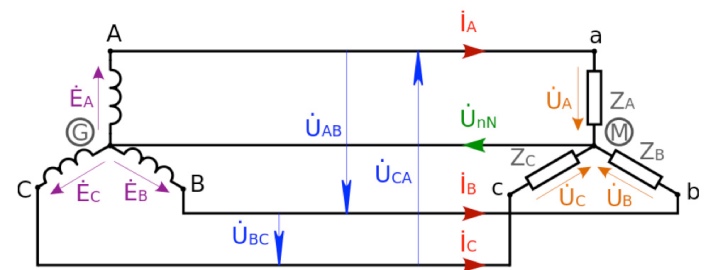

- The number of working phases. They mean the output or stator windings located inside the device. In this case, the weekend can have one phase or three. This indicator determines the purpose of the generator. The first option is available for operation at a voltage of 220 V, the second - 380 V.

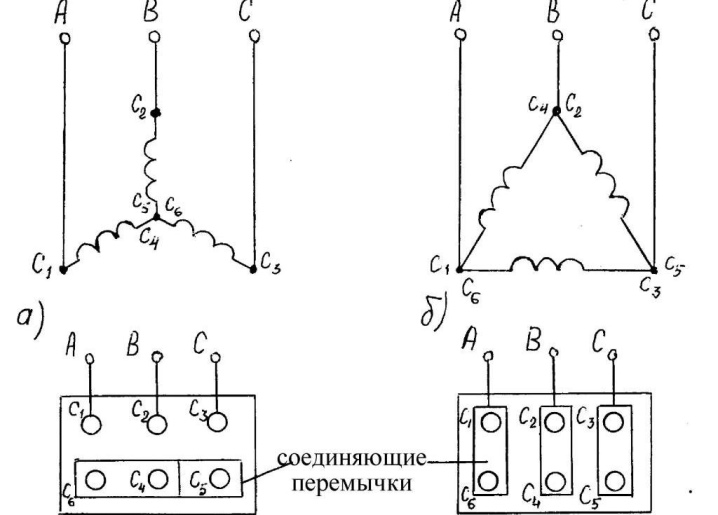

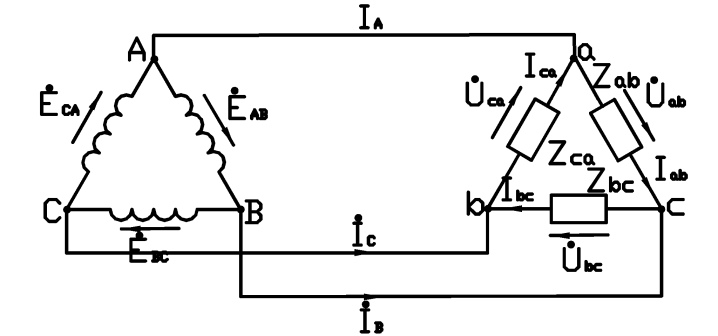

- Connection diagram... There are several ways to organize the operation of a three-phase generator. It is possible to connect the coils to the device using a star or delta connection. They can also be placed on the poles of the stationary element - the stator.

Additionally, asynchronous generators are classified according to the presence or absence of a self-excitation coil winding.

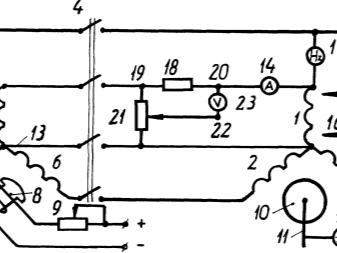

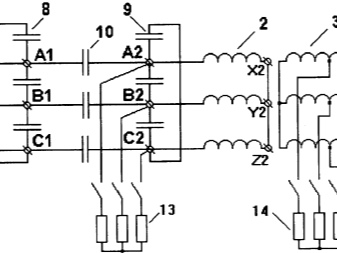

Connection diagram

Today various asynchronous motor variations... It can be single-phase or three-phase for connection. It can be provided with several windings or the modernization of the rotor design. However, in any case, the connection diagrams of the device remain unchanged.

Among the common schemes are the following.

- "Star". In this case, it is necessary to take the ends of the stator windings and connect them at one point. The method is suitable mainly for three-phase generators, which must be connected to a three-phase line at a higher voltage.

- "Triangle". It is a consequence of the first option, only the connection occurs sequentially. As a result, it turns out that the end of the first winding is connected to the beginning of the second, the end of the second - to the beginning of the third, and so on. The advantage of this method is the possibility of generating maximum power during the operation of the unit.

- "Star-triangle". This method has incorporated the advantages of the previous two. It provides soft starting and high power delivery. To connect, you will need to use a time relay.

It is noteworthy that multi-speed generators also have their own connection methods. Basically, these are combinations of "star" and "triangle" schemes in their various modifications.

Each generator is connected to the system via a certain scheme that determines how electricity is generated. Any of these methods implies the rational placement of the wires of the windings of a stationary element between the poles of its core, only in this case, the connection of these wires is carried out in different ways.

How to do it yourself?

To begin with, it is worth clarifying that it will not work to create an asynchronous mobile station from scratch... The most that can be done is to make the rotor without alteration or to upgrade the asynchronous type motor to an alternative design.

To carry out work on the modernization of the rotor, it is enough to stock up on ready-made stator from the motor and carry out a series of experiments. The main idea behind assembling a homemade generator is to use neodymium magnets. With their help, it will be possible to provide the rotor with the required number of poles to generate electrical energy.

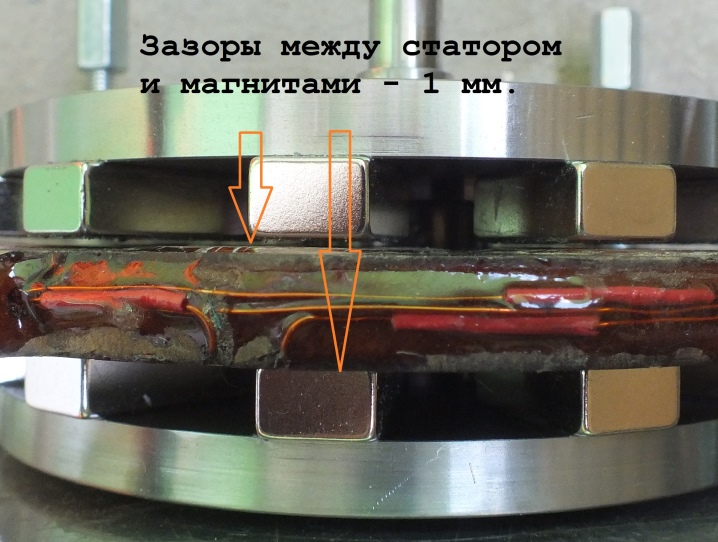

By gluing the magnets to the workpiece, which must first be planted on the shaft, and observing the polarity and shift angle, it will be possible to achieve the desired result. You will need a lot of magnets, the minimum quantity is 128 pieces. The finished rotor design is matched to the stator. When performing this procedure, it is necessary to provide a gap between the teeth and the magnetic poles of the rotor. It should be minimal.

It should be noted that due to the flat surface of the magnets, they will need grinding. Additionally, the elements will need to be turned.

In the process, it is important to regularly cool the structure.to prevent deformation and loss of magnetic properties. If everything is done correctly, the generator will work properly.

There is only one problem that can arise in the process of creating an asynchronous generator. It is difficult to make an ideal rotor design at home., therefore, if there is an opportunity to use a lathe, then it is better not to neglect it. It also takes a lot of time to fit and rework parts.

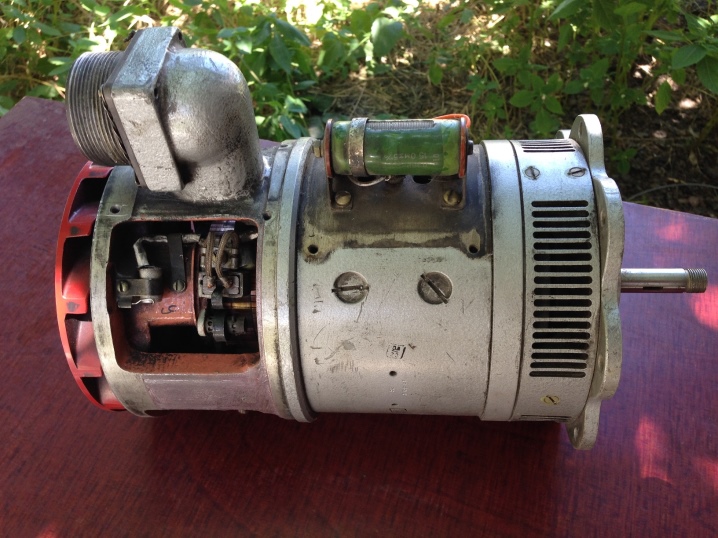

Another option with which to get a generator is conversion of induction motor used in cars... Additionally, you should purchase an electromagnet, the power of which will meet the requirements in relation to future equipment. It is worth noting that when looking for an engine, you need to take into account that its power is half the value that you want to achieve in the generator.

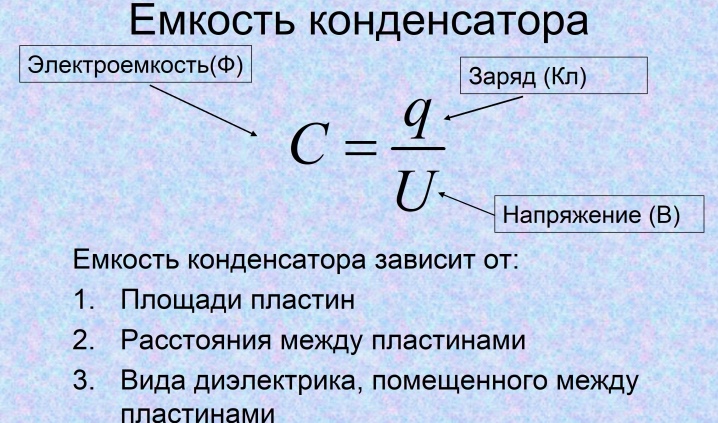

To get the desired design and organize its efficient operation, you will need to purchase 3 capacitor models... Each element must be able to withstand voltages of 600 V.

The reactive power of an asynchronous type generator is related to the capacitance of the capacitor, so it can be calculated using the formula. It should be noted that as the load increases, the power of the generator increases. Thus, in order to achieve a stable voltage in the network, it will be necessary to increase the capacitance of the capacitors.

See the following video about the principle of operation of an asynchronous generator.

The comment was sent successfully.