Features of vertical wind turbines

The wind has a great driving force that people can use for their own purposes. It is a source of clean energy. Using a wind generator, you can get additional free power. In today's article we will consider vertical types of wind turbines, their features and types.

Device and principle of operation

A wind generator is the easiest way to obtain alternative energy for the needs of a home. This device is designed to convert the force of the wind into an electrical resource. Additional devices for determining the wind direction are not required. The described device is capable of working at a low height, which allows it to be serviced without the use of equipment for high-altitude work.

The simplicity of the design and the minimum set of moving parts make this device reliable and durable. The correct shape of the blades and the original structure of the rotor make it possible to obtain a high level of efficiency from the generator, regardless of the direction of the wind. During the operation of this generator, any noise is completely absent, so it will not disturb the user and his neighbors.

There are no emissions into the atmosphere, the unit can operate for many years without maintenance.

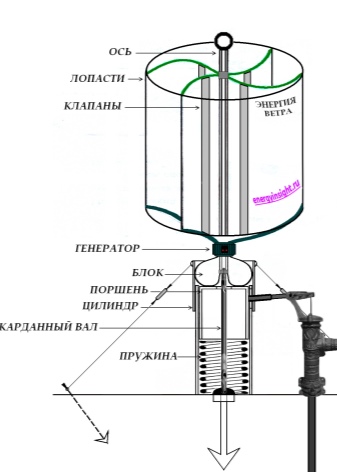

The principle of operation of the described generator is magnetic levitation. During the rotation of the rotor, impulsive and lifting forces and frictional forces arise, which brakes the rotor. The appearance of the rotating part is a cylinder fixed to the frame. The correct shape of the blades allows rotation always in one direction, regardless of the direction of the wind. Regardless of the model and type of such a generator, it will work only if the pressure of the wind flow on one side is greater than on the other.

If these conditions are met, then we will get a constant rotation of the driving axis of the generator and the generation of electricity. Since the wind has an effect on both sides of the rotating mechanism, this means that more force is required to start a vertical structure than a horizontal one. but if high-quality spare parts are used in the design, then self-promotion is possible.

With a minimum wind, high power cannot be obtained, but if the friction force is reduced in all possible ways, then this allows you to achieve the desired speed even at a wind speed of 3-5 m / s.

Advantages

As with other devices of this type, wind generators have their advantages:

- do not depend on the direction of the wind;

- the use of these devices is possible in light wind;

- installation noise is approximately equal to 30 dB .;

- an interesting and unusual product on your site will certainly interest all guests and neighbors.

But, like any device, "wind turbines" have a drawback - it is the impossibility to fully use the force of the wind due to the low speed of rotation of the rotor.

What are they?

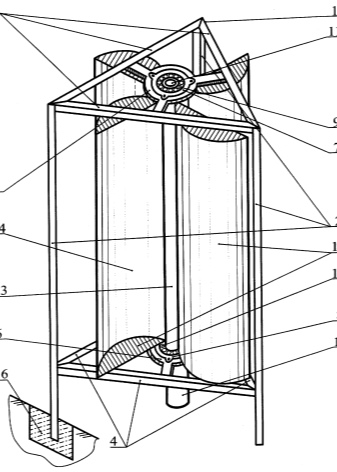

Among the vertical generators of the carousel type, which are used for domestic needs, various designs and types can be distinguished. They are very easy to maintain and not so complex in terms of construction. The main parts that need maintenance are at the bottom and are easily accessible. Consider the most famous and common types of wind turbines with a vertical axis of rotation.

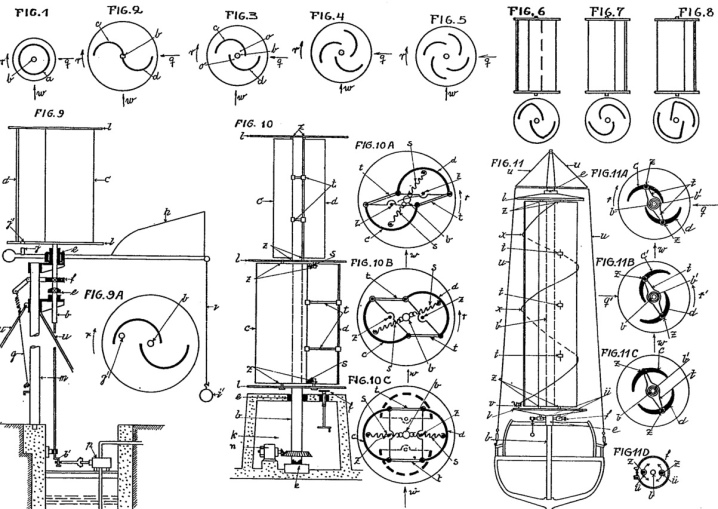

- Savounis rotor. It consists of 2 cylinders, in which the rotation speed and wind speed are independent of each other. Even with sharp wind gusts, the unit continues to rotate at the initially set speed. Under this condition, we can say that the absence of a connection between the wind speed and the generator rotation speed is an advantage, however, in this case, the air force is used only by 1/3. The geometry of the blades allows them to work only ¼ turn.

- Rotor Daria. The design can have 2 or 3 blades. The assembly and installation is very simple. Powered by manual start. The described installation does not have high power.

- Helical rotor. The rotation of this generator is uniform and smooth. The design removes excessive load from the bearings, which significantly extends the service life of the device. Installation of this type of installation is very time-consuming and laborious. The complex design has influenced the increase in the final cost of such a product.

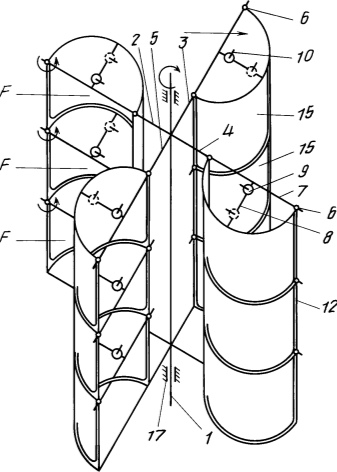

- Multi-blade rotor. This design with blades of different shapes and directions allows the device to operate even in very weak winds. This generator is considered a powerful power converter and has a high level of efficiency. The energy from the force of the wind is extracted as much as possible. This design, in addition to being expensive, has a high noise level.

- Orthogonal rotor. Such an installation begins to operate at a wind speed of 0.7 m / s. The design consists of 1 axle and blades. The noise level is minimal. In addition to all the technical characteristics, it is worth noting its interesting and unusual appearance. The service life of such a device is several years.

It should be noted that heavy blades and structures in general make it difficult to mount the device at a serious height. In addition to vertical wind generators, there are also horizontal models. Different versions of these devices have from 1 blade, their performance is higher than that of vertical ones. But they have a very strong attachment to the direction of the wind.

Review of popular models

Before considering the popular models of wind turbines, you need to understand their parameters and selection criteria for the described products. The main selection criteria are:

- maximum product power;

- the amount of energy produced for 1 month;

- the minimum air speed at which the generator can operate;

- terms of Use;

- the presence of devices that protect the installation from overloads;

- lifetime;

- product price.

Today wind generators are produced by many countries, including Russia. They are produced by several organizations:

- OOO SKB Iskra;

- CJSC "Wind Energy Company";

- LMV "Vetroenergetika";

- CJSC "Unit-drive".

Russian-made units are not as well-known and in demand in other countries as rotary models of German, Danish, Chinese and Belgian production. The world's leading wind generator companies are spending huge amounts of money on the development of new types of blades, generators, precise calculations for gear ratios. The products of these companies have a large selection of capacities from 1-10 kW and additional equipment that can be purchased separately (sets with a hub, inverter, batteries). In addition to power, there are differences in price and component parts. Russian companies produce wind generators with different types of rotors and maximum device power. The following models of the new generation are considered the best-selling products.

- VUE-1.5. This is a compact unit that can be transported by any type of transport. In installation and operation, it is simple and straightforward. This little generator is virtually silent. Has a rated power of 1.5 kW. The output voltage is 48 V. The wind speed for normal operation should be in the range of 2.5-25 m / s.

- VUE-3 (6). Such a device is intended for autonomous supply of a small consumer (private house). The rated power of the described installation is 3 kW, but with the installation of additional equipment (inverter and batteries), the power can be increased to 6 kW. Output voltage 48 V. Required wind speed for operation - from 4 to 30 m / s.

- VUE-30. The installation is focused on powering a large house or several houses. Its rated power is 30 kW. The output voltage has a range of 90-400 V. The wind speed for the installation should be from 4-60 m / s.

How to do it yourself?

A wind generator is not a very complex structure that almost anyone can assemble if he has the initial skills in working with a hand tool and has knowledge in electrical engineering. Consider the process of assembling the simplest wind generator for users who are starting to master alternative energy sources.

Tools and materials

In order not to be mistaken in size and assemble everything correctly, you can use any ready-made drawing from the Internet or you can draw your own and check it in practice. To manufacture a reliable and high-quality structure, you will need:

- sheet metal for the manufacture of blades with a thickness of 0.8-0.9 mm, it should not be too thin and weak so that it is not bent or broken by a strong gust of wind, but too thick material is also undesirable, since excess weight of the structure will lead to rapid wear of the bearings;

- steel plate 40 mm or other diameter;

- steel pipe 25 mm;

- axle shaft from any car with a bearing;

- steel corner;

- 2 pulleys of different sizes;

- car generator.

Manufacturing scheme

The assembly diagram of a homemade wind generator is simple, you can always add your own design solutions to it. 4 blades need to be made from sheet metal, the size of which will be 1000 by 800 mm. A steel strip is used to fasten the blades together. As a result, the design should resemble the shape of a drum. The blades should point from the center to the outside. This direction will allow you to have a larger sail to capture the air flow, and when the blade turns, its streamlined shape will have minimal air resistance.

A vertical stop is made of a steel pipe, which is attached to the axle shaft on one side, and the resulting blades are installed on the opposite side.

The axle shaft itself is attached to bearings on bearings, which is made in any form and from the available materials. After the structure is assembled, it's time to place the generator on it.

For greater productivity, we need pulleys of different radii. The one that is larger is attached to the mast, and the smaller one is attached to the generator itself. If the generator has its own pulley, then you can use it. After that, the generator is ready to generate current, but it needs to be sent to the place we need. To do this, we attach wires to the contacts. It is desirable that they are copper and have a cross section of at least 1.5 sq. mm.

Service

Like any technique, wind generators need regular maintenance. For high-quality and trouble-free operation, it is necessary to lubricate all moving parts of the structure. This procedure must be carried out at least 2 times a year. Since the structure has constant vibration, it is necessary to tighten loose nuts and wire fasteners during maintenance. Weak and slack ropes must be tightened and the blades inspected for cracks and tears.

In such products, it is advisable to use closed-type bearings so that less moisture and dust gets into them, and the nuts should have a self-locking plastic ring. This will not relieve the user of the need to maintain the mechanism, only provide a longer service life. If traces of corrosion are found on metal parts, it is necessary to take timely measures to protect the metal.Rust paint will fix the situation.

Such maintenance will help to extend the life of the unit and ensure the correct operation of the unit without jamming and difficult turns.

Where to install?

One of the most important conditions for the operation of a wind turbine is the choice of its installation site. The ideal option for the operation of the described device is an open area and an installation point above all extraneous structures and natural obstacles to the wind. (houses, trees, hills). If these requirements are neglected, then the efficiency of your generator will drop. If it is possible to place a vertical-axis generator on the river bank, then this is a very good solution, since the winds from the water blow especially often. A good option for placing your generator is on an artificial or natural elevation. Field locations are also suitable for placing this fixture. Simply put, any terrain where there is no obstacle to the wind will suit him.

It is possible to place a generator of this type within the city or in densely built-up areas, but only on the roof and as high as possible, this is the only way you can achieve the best result. Installing this device on the roof of an apartment building can be difficult. Written consent from all tenants and permission from the management company will be required. In addition, the noise of the unit can be heard on the upper floors, because of this, an already installed structure may need to be removed. Placement on the territory of a private house is much easier and faster, since you do not need to take permits and negotiate.

So that your generator does not interfere with anyone, it must be placed at a distance of 10-15 m from residential buildings, and then it will not interfere with anyone.

A vertical wind turbine with a multiplier is presented below.

The comment was sent successfully.