Choosing a gas generator

The choice of a gas generator is a very important matter that requires attention and accuracy. We'll have to understand the features of inverter and other gas generators for generating electricity, in the specifics of industrial and domestic power generators using natural gas.

Features and device

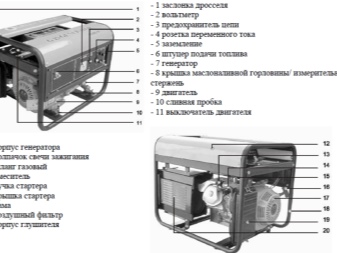

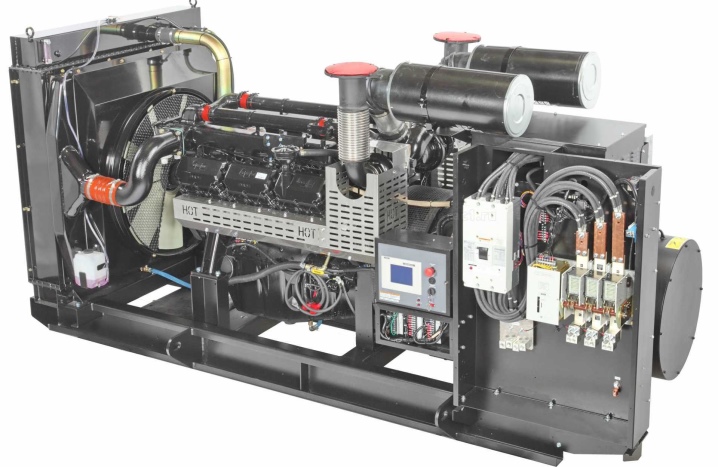

A gas generator, as it is easy to understand by its name, is a device that releases the latent chemical energy of a combustible gas and, on this basis, creates a certain amount of electric current with certain parameters. Inside is a typical combustion engine. A typical design involves the formation of a mixture outside the engine itself. A combustible substance supplied to the working volume (or rather, its combination with air in a certain proportion) is ignited by an electric spark.

The principle of electricity generation is that the internal combustion engine uses the Otto cycle, while the motor shaft rotates, and from it the impulse is already transmitted to the generator.

The gas supply from outside is regulated by means of a gas reducer. Another gearbox (already purely mechanical) is used to control the twisting motion. Gas-fired generators can act as cogeneration systems, which is not available to their liquid counterparts. Some of this equipment is even capable of producing "cold". It is obvious that the areas of application of such systems are wide enough.

Where is it used?

Electricity generation at a gas-fired power plant is useful for:

- cottage settlements;

- other settlements remote from the city and from ordinary power lines;

- serious industrial enterprises (including as an emergency resource);

- oil production platforms;

- downhole sections;

- uninterrupted power supply of water supply and industrial treatment complexes;

- mines, mines.

A large indoor or outdoor natural gas generator may also be needed:

- at a small and medium-sized production facility;

- in a hospital (clinic);

- at construction sites;

- in hotels, hostels;

- in administrative and office buildings;

- in educational, exhibition, trade buildings;

- at communication complexes, television and radio broadcasting and telecommunications;

- at airports (airfields), railway stations, seaports;

- in life support systems;

- at military facilities;

- in campsites, permanent campgrounds;

- as well as in any other area where autonomous power generation is needed, optionally interfaced with centralized heat supply systems.

Types and their characteristics

There are several types of gas generators that differ in some characteristics.

By time of continuous work

Such a wide variety of uses for gas generators means that a universal model cannot be created. The possibility of permanent operation or at least long-term use can only have water-cooled systems. Appliances with air heat dissipation are designed for short-term switching on, mainly in case of minor power failures. The maximum time of their continuous action is 5 hours. More detailed information can be found in the instructions.

By power

A gas power plant with a capacity of 5 kW or 10 kW is suitable for powering a private house.In larger private homes, appliances with a capacity of 15 kW, 20 kW, and so on are required - sometimes it comes to 50-kilowatt systems. Similar devices are in demand in the small commercial sector.

So, a rare construction site or a shopping center will require over 100 kW of electricity.

If it is necessary to supply current to a cottage village, a small microdistrict, a port or a large plant, then systems with a capacity of 400 kW, 500 kW are needed. and other powerful equipment, up to the megawatt class, all such generators produce a current of 380 V.

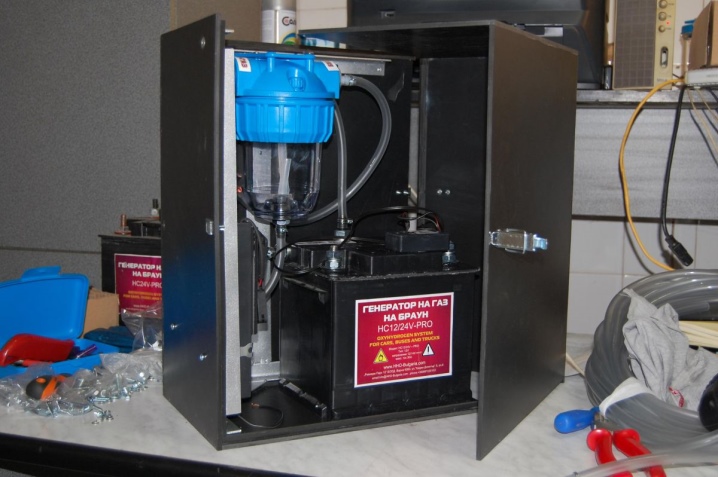

By type of fuel

Liquefied gas generators powered by a cylinder are quite widespread. In well-developed and well-developed territories, trunk systems are often used, into which natural gas is supplied from a pipeline. If it is difficult to make a choice, you can opt for a combined performance. Attention: connection to supply lines is made only with official permission. It is quite difficult to get it, it will take a lot of time, and you will have to draw up a lot of paperwork.

By the number of phases

Everything is quite simple and predictable here. Single-phase systems are preferred for specific equipment capable of receiving only single-phase current. In normal household conditions, as well as for the power supply of industry, it is more correct to use a three-phase generator. When there are only three-phase consumers, then the current source must also be 3-phase. Important: it is also possible to connect single-phase consumers to it, but this is done using a special method.

By cooling method

It is not so much about air or liquid heat removal, but about their particular options. Air can be drawn directly from the street or from the turbine room. It is very simple, but such a system is easily clogged with dust and therefore is not particularly reliable.

A variant with internal circulation of the same air, which gives off heat to the outside due to the heat exchange effect, is more resistant to external clogging.

And in the most powerful devices (from 30 kW and more), even the optimal air heat removal schemes are ineffective, and therefore hydrogen is more often used.

By other parameters

There are synchronous and asynchronous gas generators. The first option is clearly more expensive, however, it allows you to abandon the auxiliary stabilizers. The second is more cost-effective and optimal as a backup current source. Another important property is the method of starting the generating equipment. It can be included:

- strictly by hand;

- using an electric starter;

- using automatic components.

A very serious property is the volume of the sound. Low noise devices are preferable in many ways. However, it should be understood that even "loud" generators can be equipped with special covers, and the problem is successfully solved. The inverter machine can generate a large amount of current, while still delivering a steady voltage.

Inverter-based units are useful for travelers, owners of summer cottages, country houses, they are also useful for powering small repair equipment.

The inverter generator is also often the choice of hunters and fishermen. For the simplicity and stability of work, many experts praise the gas-piston type of power plant. The high efficiency testifies in its favor. The minimum power is 50 kW. The highest level can reach 17 and even 20 MW; in addition to the wide variation in power, it is worth noting its suitability for a wide range of climatic conditions.

Special attention should be paid to gas turbine generators. Such systems are composed of a selection of gas turbine engines operating in conjunction with the main unit. Generation varies over a very wide range - gas turbine complexes can generate 20 kW, and tens, hundreds of megawatts. A side effect is the appearance of a large amount of thermal energy.This property is valuable for large commercial projects.

Top Models

Among the household and industrial options, one can single out models that are especially popular.

Household

A very good option is Greengear GE7000... The proprietary Enerkit Basic carburetor testifies in favor of this model. This device is easy to use.

A two-stage regulator is provided. There is also a throttle valve. As required, the voltage rating varies from 115 to 230 V.

Key parameters:

- country of the brand - Italy;

- country of actual production - PRC;

- calculation for liquefied propane-butane;

- thoughtful electric starter;

- combustion chamber capacity 445 cub. cm;

- gas consumption in the limiting mode 2.22 cubic meters. m in 60 minutes.

Model Mitsui Power Eco ZM9500GE not purely gas, but of the bi-fuel type. It always operates with an output voltage of 230 V and provides a single phase current. The brand is registered in Japan and released in Hong Kong. Electric and manual starter provided. The combustion chamber has a capacity of 460 cubic meters. see gas.

When choosing the cheapest gas generators, you should pay attention to REG E3 POWER GG8000-X3 Gaz... This model provides for starting both manually and with an electric starter. A well thought-out design allows you to work confidently even with a reduced pressure in the gas line. The device weighs 94 kg, produces three-phase current and is cooled by the ambient air.

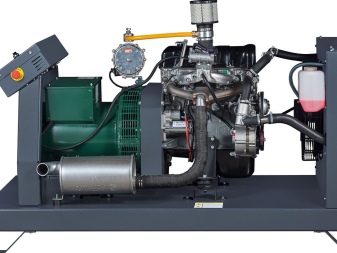

Industrial

In this segment, the Russian MTP-100/150 generator sets, manufactured in Barnaul, stand out. In addition to gas piston devices, this selection also includes utilization devices. Optionally, the equipment is equipped with electric units made in accordance with the 1st category. The systems are suitable for both main and auxiliary (backup) power supply. Associated petroleum gas can be used along with natural gas.

Other properties:

- correction of current parameters in manual and automatic modes;

- The battery is charged automatically;

- the readiness to accept the load during autonomous activation is indicated by a signal;

- local control of starting and stopping the system from the operating panel.

Gas reciprocating power plants are actively supplied, for example, NPO Gas Power Plants company... The TMZ-based model has a total capacity of 0.25 MW. The motor shaft makes up to 1500 turns per minute. The output is three-phase alternating current with voltage of 400 V. The level of electrical protection complies with the IP23 standard.

How to choose?

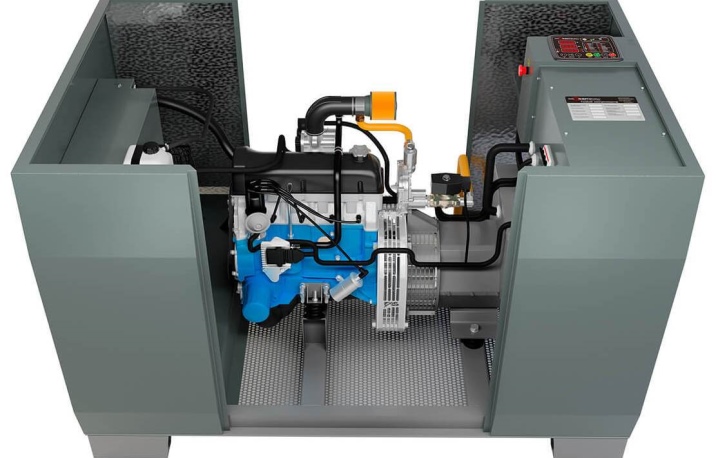

Getting electricity for a summer cottage or a private house using a gas generator is, of course, a very attractive idea. However, not all models are suitable for specific tasks. First of all, you should decide on whether the generator will be installed indoors or outdoors. These are completely different classes of equipment, and they are not interchangeable!

The next important point is stationary placement or mobility (usually on wheels).

Until all these points have been determined, there is no point in choosing by other parameters. Then it will be necessary to find out:

- the required electrical power;

- the upcoming intensity of use;

- responsibility of the working area (the required degree of reliability);

- the required level of automation;

- gas consumption;

- type of gas consumed;

- the ability to use additional non-gas fuel (optional);

- cost of equipment.

In domestic and industrial conditions, bottled propane-butane and pipeline methane are most often used. Among propane-butane, summer and winter varieties are additionally distinguished, differing in the proportion of gas mixing.

It should be borne in mind that generators can be reconfigured, and this feature is also worth looking into when buying. Selection by power indicators is exactly the same as for gasoline and diesel analogues.

Usually, they are guided by the total capacity of consumers, plus they leave a reserve of 20-30% for a possible expansion of their composition.

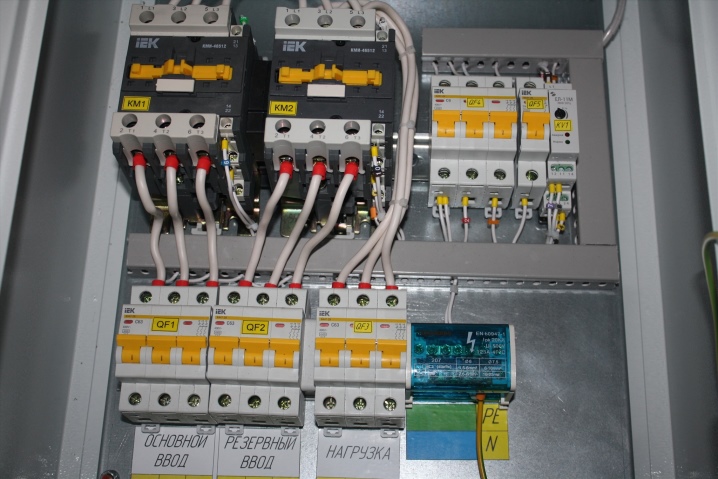

Besides, the excess of the total power over the calculated values should also be due to the fact that the generators work stably and for a long time only when the load does not exceed 80% of the maximum level. If the power is selected incorrectly, the generator will be overloaded, and its resource will be used up unreasonably quickly. And the cost of fuel will rise excessively. Attention: when connected to a three-phase switchboard through the ATS, it is quite possible to buy a single-phase device - it will cope with the task no worse than a three-phase analogue.

When choosing a generator for an engine, there are two real options - a Chinese manufacturer or some transnational company. A number of states have companies supplying budgetary single-cylinder air-cooled engines, but there are no such companies in Russia. When choosing equipment that is used only periodically and does not experience a significant load, overpayment for a trademark is inappropriate. In this case, it is quite possible to restrict ourselves to ordinary Chinese equipment - all the same, the products of leading companies will work for at least 5 years. For critical areas, it is more correct to choose models with an increased working resource and increased fault tolerance.

There is much more variety of proposals in the segment with liquid heat removal. There are already quite decent Russian motors. They are reliable enough and can be repaired without any problems.

For cold regions, it is appropriate to select a generator designed for a winter grade of gas. An alternative solution is the addition of an AVR and a cylinder heating complex, which also excludes the occurrence of failures.

It is very good if, in addition to the gearbox, another safety system is provided - a valve based on an electromagnetic principle. It will completely block the flow of gas into the reducer itself if the voltage suddenly disappears. An important parameter is the level of electrical protection. If the unit complies with the IP23 standard, it can be as good as it wants, but it is not protected from moisture. Equipment for indoor installation should be selected only if high-quality supply and exhaust ventilation and an exhaust gas discharge system can be prepared there.

It is necessary to find out information about service and read reviews. With regard to brands, the best reputations are for:

- Generac;

- Briggs end Stratton;

- Kohler-SDMO;

- Mirkon Energy;

- Russian Engineering Group.

Recommendations

Even the best gas generators can operate stably in freezing temperatures rather than freezing temperatures. If possible, they should be protected from the cold - including when the manufacturer indicates the frost resistance of his products. Ideally, such equipment should be taken to a separate room. LPG fuel should only be supplied to boiler rooms at ground level or higher structures. For natural gas generators, this requirement is optional, but highly desirable. Even the smallest equipment should be located in rooms or halls with a capacity of at least 15 m3.

When choosing a site, it is necessary to provide for free access to the unit for employees of technical and service services. They must be able to fit freely around any piece of equipment.

High-quality ventilation, sufficient level and regularity of air exchange are also critically important. Any exhaust must be taken out of the premises (nozzles are provided for this purpose). Another significant requirement is the availability of forced ventilation and fire extinguishing equipment wherever gas generators are used.

In any case, the device can only be installed in accordance with the technical plan, which is coordinated with the official authorities. The centralized connection is made according to a carefully calculated installation plan, and its preparation is very difficult and expensive.Bottled gas is easier, but you will need another room to store the containers. Such fuel itself is more expensive than that supplied through the pipe. It is imperative to take into account the pressure of the incoming mixture.

See below for an overview of the gasifier.

The comment was sent successfully.