The principle of operation and features of wood-fired gas generators

Energy has long been the basis of human economic activity. And today we will consider the principle of operation of a wood-fired gas generator, one of the most environmentally friendly and efficient devices. It can be used for various purposes: for heating a house, for generating electricity, as fuel for a car engine.

Moreover, if earlier the gas generator was only an industrial one, today it is not a problem to find a household analogue.

Main characteristics

Gas power generators are special installations that are used to convert gas into electricity by burning it in chambers under high pressure. Recently, you can find and wood-fired gas generator. In this case, wood will be the fuel. And more and more often they work for sawdust - this gives a rather high efficiency of such devices.

If we talk about gas, then its advantage will be that it heat capacity higher than that of diesel type or gasoline, and the cost will be slightly lower. Yes and using a gas generator at home is quite convenient, because there are no harmful substances or odors during work. In general, even the simplest home-made device can supply the home's electricity needs... Users of such devices note that they are indispensable in places where it is not failed. The wood-fired gas generator is used by some as a device that propels a car. According to them, it is significantly cheaper than using gasoline.

But such a device is not too cheap, because its price starts at 35 thousand rubles. However, you can do it yourself.

Advantages and disadvantages

A gasifier that runs on wood has a large number of positive characteristics and not too many disadvantages. First, you should talk about the benefits.

- High efficiency. This indicator for gas generators is kept at 90%, which is pretty good. For comparison, solid fuel boilers have an efficiency of 75%.

- A number of models are equipped with automated combustion control mechanisms.

- The fuel burns out completely. One tab of firewood provides up to a day of operation of such a device. And if instead of firewood you use coal, then the bookmark may be enough, in general, for several days.

- Firewood usually burns out completely, which leaves a very small amount of ash. For this reason, there is often no need to clean the device.

- Any solid fuel can be used as fuel.

- Even long firewood can be thrown into the combustion chamber, so there is no need to cut it into small chips.

- The emission of harmful substances during the operation of the device will be minimal. For this reason, a number of motorists have paid attention to such devices.

- Substantial cash savings on fuel.

If we talk about the shortcomings of wood-fired gas generators, then there are only three of them.

- Factory made models are expensive.

- Condensation sometimes forms inside the chimney. To avoid its formation, the temperature inside the gas generator must be 60 degrees.

- Most models have fans at the air outlet inside the air separation compartment.They can operate in manual mode, but some models require electricity to operate, making the gas generator dependent on electricity.

Device and principle of operation

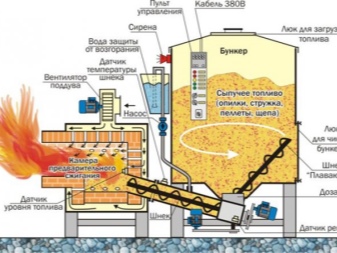

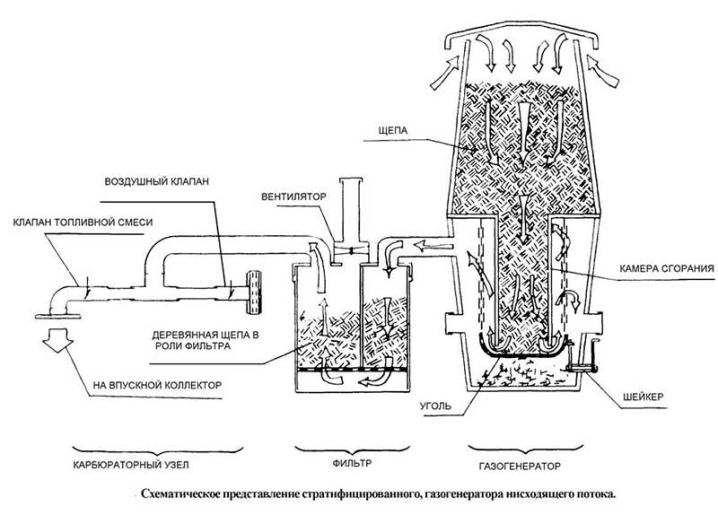

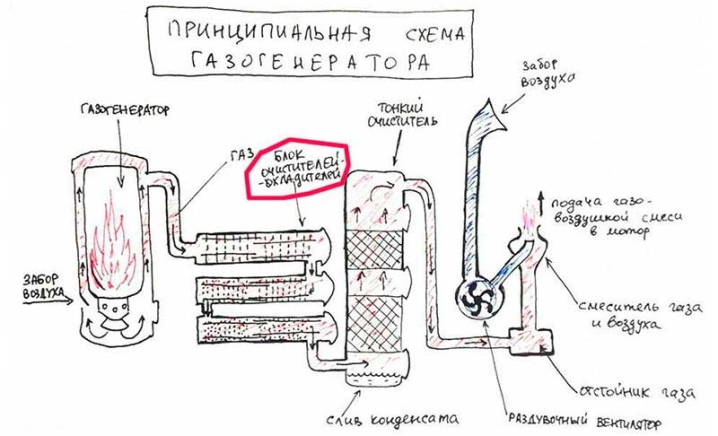

The device in question has a simple design, because all the processes that take place inside it, based on pyrolysis type combustion... That is, the principle of operation will be the same as in pyrolysis boilers, in which wood burns with a lack of oxygen, emits many different gases. The wood-fired gas generator consists of the following elements:

- bunker;

- hulls;

- combustion chambers;

- loading hatches;

- grates of the grate type.

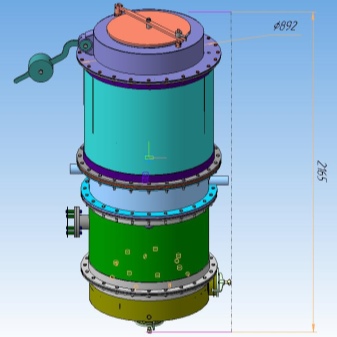

Now let's say a little more about them. Frame It is usually made of sheet steel and is either rectangular or cylindrical. Bottom welded to it legs... If we talk about the hopper, then this element is also made of sheet steel, which contains little carbon. He usually happens cylindrical or rectangular... It is inserted into the housing and attached to its walls with screws. And also must be lid, which will close the upper opening leading to the hopper. Asbestos is commonly used as a sealant.

Combustion compartment located on the bottom and made of steel, which contains a lot of chromium. It is here that solid fuel combustion occurs with an insufficient amount of air. Between the internal parts of the body and this element, there are usually asbestos cords... And on the walls on the sides there are tuyeres for oxygen access, through which it is supplied to the combustion chamber. The lances are connected to the air distribution tank, which communicates with the environment. When oxygen comes out, it overcomes check valve. It is necessary to block the exit of the gas formed during the burning of firewood into the atmosphere.

Grate usually located at the bottom of the gasifier. It must keep the fuel hot. In addition, through special holes, ash, which is formed during the burning of wood, ends up in the ash pan.

If we talk about loading hatches, then usually the device has three of them. First is installed at the top and its cover opens horizontally. For sealing, the already mentioned asbestos cords are used. By the way, modern devices are equipped with a special shock absorber spring at the hatch attachment point, which automatically works if the pressure inside the gas generator exceeds a certain level. And under its action, the hatch simply opens.

Second the hatch is at the level of the recovery area and is loaded with fuel. A third the hatch will be located at the bottom of the generator next to the ash pan. It will be used for cleaning.

If speak about principle of work, then, first, the fuel enters the drying zone. It is located at the top of the unit under the loading hatch. The fuel is dried here at a temperature of almost 200 degrees.

After that, the fuel enters the dry distillation area, which is located below. Here, the already dried fuel is charred, because the temperature will be 2 times higher and is 500 degrees.

This removes a number of organic acids and gums.

Further, the fuel enters the combustion area, which is located even lower. Here it completely burns out under the influence of a temperature of 1200 degrees. It is here that oxygen is supplied through special lances. When burning, carbon dioxide and carbon monoxide gases are released.

The last one will be recovery zone. Here, the gases that were released earlier rise and enter this zone. Coal is placed here through the special hatch, which is held on the grate. The gases react with coal to create carbon monoxide. But coal contains water, due to which the formation of hydrogen, methane, nitrogen and a number of hydrocarbon-type compounds also occurs.

This mixture of gases is cleaned of impurities and then combines with air.And it can be used for some household needs.

How to do it yourself?

Now let's try to figure out how to make such a wood-fired gas generator with our own hands. First, we will consider what we need, after which we will try to understand the manufacturing process of this device.

Preparation

So, to create a gas generator yourself, you will need to prepare:

- used gas cylinder;

- the barrel from which the gasifier body will be made;

- welding machine;

- several screws;

- valves and filters for gas cleaning, which can be purchased in specialized stores.

In addition, you will need to prepare blueprints model that interested. Their use should not be neglected, because they allow you to fit all the necessary components to each other as accurately as possible and save you from any mistakes and unnecessary mistakes. Therefore, it is better to have them at hand and carefully read them before starting work.

To create the case, you will need to prepare the corners and pre-cut and cut according to templates sheet steel. Prepare for the hopper sheet products. And you will also need heat-resistant steel, from which the combustion chamber is made. For the neck of the combustion chamber, asbestos gaskets are needed, with which it is separated from the body.

Manufacturing scheme

Let's try to figure out how to assemble a wood-fired gas generator with our own hands. So, to begin with, it is produced assembly of the body from pre-prepared steel sheets, which are connected to each other by welding. After that, the legs should be welded from below.

The second stage produces creation of a bunker. Its shape can be anything you like. After it is done, it must be placed in the case and must be fixed inside with bolts. It should be completed with a lid.

The next step will require place the container in the lower area of the hopper, which will be the combustion chamber... It can just be cut out of a used gas cylinder. Here you should be careful and before working with the cylinder, fill the container with water so that the residual gas does not accidentally explode. We cut off the upper part, and make the remainder a combustion compartment.

The next step requires create oxygen distribution box... Its installation takes place behind the body. A check valve is installed at the outlet of it.

The place for installation must strictly correspond to the plan.

The grate is made of cast iron. The penultimate stage will be creation of a device for oxygen supply and gas outlet. They must be installed at the top and bottom of the gas generator respectively. And the last step will be the installation of the chimney.

Security measures

If we talk about security measures, then first of all you should be careful when working with a used gas cylinder. It is imperative to fill it with water before starting work, because gas residues can be stored inside it, and when sawing without water, they can explode, which is fraught with injury and damage.

One more point to be mentioned - all actions should be carried out exclusively in accordance with the information on the drawings. This will ensure that everything is done correctly and that the wood fired gasifier will actually work as planned. In addition, when creating such a device, only high-quality materials should be used that will withstand high temperatures and guarantee the durability of the structure and its strength.

It should be said that almost every person who has at least a little experience in working with ordinary tools can make a wood-fired gas generator with their own hands. And this is a great alternative to factory models, the price of which is significantly overpriced.

For information on how to make a wood-fired gas generator, see the next video.

The comment was sent successfully.