Aerated concrete or gas silicate: which is better and how they differ?

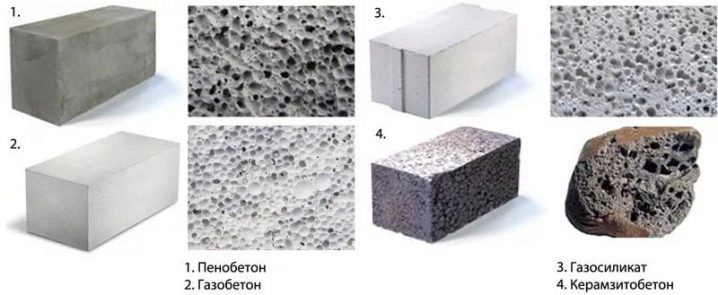

Building materials are found today the most diverse, and sometimes it is difficult for non-specialists to understand their features. A striking example is the confusion between gas silicate and aerated concrete, which have rather similar characteristics. But this similarity in no way means complete identity.

What is the crux of the problem?

Energy resources and heat supplied through the main heating pipes are becoming more and more expensive from year to year. Therefore, the demand for construction materials is increasing, which thoroughly restrain heat. Optimum results are achieved when using heat-insulating concrete types. Misunderstanding arises due to identical parameters and similar areas of use. Sometimes even experienced builders cannot quickly determine what is the difference between gas silicate and aerated concrete. Individual manufacturers are adding to the chaos by randomly naming their products.

Preparation methods

To understand the specific features of materials, you first need to figure out how exactly they are formed. Aerated concrete is made using Portland cement or other cement, to which sand and lime are added. But gas silicate belongs to the group of cellular concretes of silicate nature. It is formed from a combination of sand with lime (64 and 24%, respectively). The rest comes from additional additives and water.

The thermal characteristics of the aerated concrete block are created due to the porous structure. It is possible to form it in production using the swelling of the main mixtures due to the introduction of substances that form pores. The cavities of the finished product are bubbles with an outer section of 0.1–0.3 cm. These cavities account for 70 to 90% of the total volume of the material. If the design is made according to all the rules, the cells filled with air are dispersed in a uniform manner.

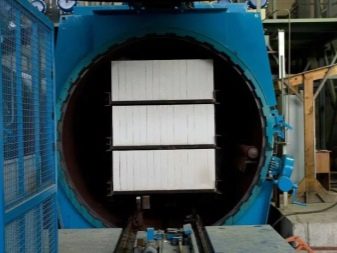

Any concrete must certainly harden. Heat treatment with steam helps to strengthen the gas silicate block. To do this, the workpiece is placed in an autoclave, where it is exposed to a temperature from +180 to +200 degrees. At the same time, the pressure reaches 8-14 atmospheres. With aerated concrete, the situation is different, it can harden both in an autoclave and in the open air, depending on the nuances of the technology.

Pressure treatment is considered preferable because it has the following characteristics:

- increases the rate of setting;

- makes the material stronger;

- guarantees stable geometry;

- drastically reduces shrinkage in use.

Both the gas silicate and the autoclaved aerated concrete are almost pure white in color. But the gray color unambiguously indicates that aerated concrete is in front of the consumer, processed without applying pressure.

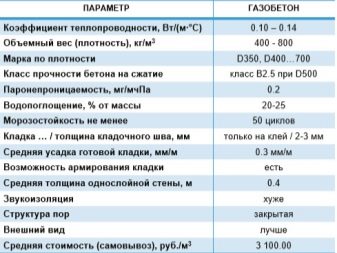

Evaluation of any of the listed materials is carried out taking into account such parameters as:

- density (specific gravity);

- water absorption;

- heat transmission;

- compression resistance - characterizes the mechanical strength;

- frost resistance - measured in the number of cyclical freezing and thawing;

- water vapor permeability;

- total thickness of the masonry.

Familiarization with the main technological characteristics shows that aerated concrete and gas silicate are not inferior to a friend in the following parameters:

- steam passage through the thickness of the material;

- protection from fire;

- suitability for cutting with hand saws;

- ecological properties;

- prevention of cold bridges;

- price;

- suitable for finishing with a wide range of decorating plasters.

How to choose and apply?

All this does not mean, however, that aerated concrete and gas silicate really coincide with each other in all respects. In this case, the difference is already manifested in the composition of the adhesive solutions offered by the manufacturers of certain blocks. The adhesive is a combination of sand and cement, the specific properties of which are determined by additional additives. It is only thanks to such additives that it is possible to compensate for the styling speed. A classic astringent solution, even a very good one, will not help in this case.

When comparing different materials and trying to evaluate which one is better, it is important to understand that all these judgments are relative. The gas silicate blocks improved by pressure will definitely be of high quality, but a lot of additional money will have to be paid for their merits. Low density gas structures become brittle, but this is "justified" by the increased protection against heat loss. Aerated concrete, obtained without an autoclave, is rather fragile, but it can be obtained independently. These blocks are easy to make on site, saving money. The gas silicate block under identical processing conditions differs from aerated concrete for the better in almost all properties, except for liquid absorption, therefore, gas silicate is used only where the humidity does not exceed 60%. In more severe conditions, the material degrades too quickly.

Important: if water penetrates into the pores of both one and the other material, the thermal parameters are significantly reduced.

This means that the facades must be protected from atmospheric moisture.

To solve a similar problem, use tools such as:

- facade paint;

- plaster;

- siding;

- plaster in the form of a thin layer.

A facing brick with a gap for air blowing (the gap is 300-400 mm) can also be used. It is recommended to cover the outside wall with an extended roof overhang. The larger it is, the less dangerous the precipitation is. All finishing materials that are applied over aerated concrete and gas silicate must have a good level of vapor permeability. If this condition is not met, excellent ventilation is required.

The passage of steam through insulation, paint or plaster should be more intense than through structural material. Recommended additional insulation using mineral wool. When finishing or heat protection is performed in several layers, the penetration of steam into each next layer should be more active than into the previous layer. Failure to comply with this requirement may result in condensation. Pockets of mold will soon appear.

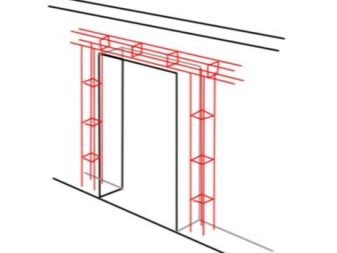

If you have to fix suspended furniture made of gas silicate or aerated concrete, dowels are used. Aerated concrete blocks are additionally fastened using anchor bolts. For both types of structures, foundations with thoroughly calculated parameters and dimensions should be created. It is also advisable to prepare waterproofing. Strengthening is performed on the first and every fourth row. It is also advisable to reinforce the door and window openings.

Additional Information

Self-production of aerated concrete is mostly done in forms, divided into standard sizes. The purchase of complex and expensive cutting devices does not justify itself. It is important to remember that with an identical average density of a substance, gas silicate retains heat better. Therefore, it is recommended to use it in the coldest places. The choice of aerated concrete or gas silicate does not affect the speed of construction.

Gas silicate is also preferable where there is a need for enhanced sound insulation. But its resistance to fire is somewhat weaker, as is its service life.The aesthetic characteristics of gas silicate are higher than that of aerated concrete, but it is worth remembering that everything is so unambiguous only when comparing materials without external finishing. Therefore, this circumstance is important only with maximum cost savings. Summarizing what has been said, we can conclude: the final choice depends only on personal priorities, with the exception of individual cases when the situation allows an unambiguous decision to be made.

When you need special geometric accuracy of dimensions and shapes, the choice in favor of gas silicate is fully justified. When laying on a mortar of cement and sand is planned, you need to use aerated concrete that has not been autoclaved. The advantage of gas silicate blocks is improved grip between parts with grooves and ridges. Protect both materials from moisture immediately after the completion of the shrinkage of the structures. Important: when buying ready-made blocks (both gas silicate and aerated concrete), you need to give preference to the products of well-known companies.

See below for the advantages of gas silicate or aerated concrete blocks.

The comment was sent successfully.