Sibit characteristics and its use

There are many materials on the market for construction products, including sibit. Due to its characteristics, it is suitable for cold and southern countries. The use of such blocks allows you to quickly erect durable buildings with good thermal insulation. The material is popular not only in industrial but also in private construction.

What it is?

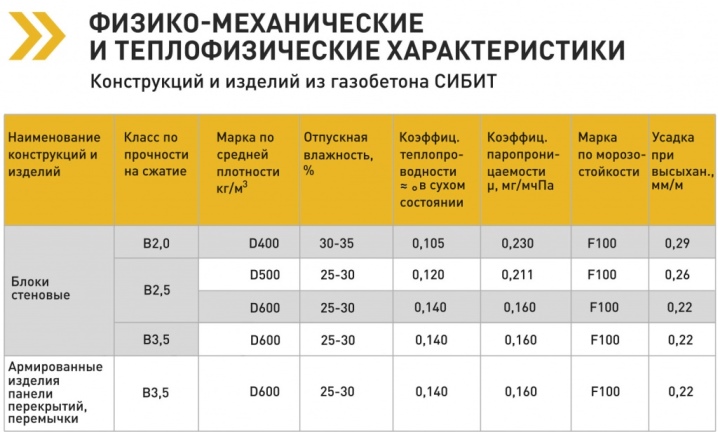

Sibit is a brand of aerated concrete, the word is made up of two other names: the Siberia plant and the Itong company. The production is located in the city of Novosibirsk, while using the technologies and equipment of the German company, which is the first manufacturer of autoclaved concrete. The material is lightweight, but durable, which explains its popularity. There are several advantages of Sibit.

- Low thermal conductivity. In comparison with brick, this figure is 4 times less. Sibit buildings can save up to 20% on heating, which is quite profitable, especially in the northern regions. In summer, the indoor temperature will remain at a comfortable level.

- Cold resistance. According to the GOST regulations, aerated concrete structures must withstand a certain number of winter cycles. Sibit's frost resistance is much higher than the minimum parameters. Blocks maintain their performance for 200 cycles due to their bubble structure. Moisture can accumulate in the pores and then evaporate freely, so the concrete does not crack.

- Ease. Compared to brickwork, a square meter laid out of sibit blocks weighs 5 times less. This allows you to save on pouring the foundation, avoiding the need to install powerful supports. In addition, installation work does not require the use of special equipment and takes less time.

- Water vapor permeability. Indicators are 0.17 g / m2, which is 6 times higher than that of bricks. This characteristic allows you to understand how breathable the material is. With the free evaporation of moisture in the room, an optimal microclimate will be maintained. The house from Sibit will not have problems with mold and fungi, residents will not suffer from dry air.

- Fire safety. Aerated concrete is made from natural components that are not prone to flammability. Depending on the characteristics of the structure, it will be able to withstand a fire load from 3 to 7 hours if you use Sibit blocks for construction.

- Versatility. Plates from this material can be used for the installation of floors and roofs. They allow you to turn the attic into a residential attic and maintain a comfortable temperature there, as well as save a little during construction. Also, walls are erected from sibit, but it is not recommended to load them with heavy objects - this can be considered a small minus. When designing an interior, it is better to provide for floor cabinets, and not wall cabinets.

Among the shortcomings, you can include the need for finishing - you will have to purchase additional materials to create a comfortable and attractive indoor environment. Outside, the building will also need to be protected from negative atmospheric influences. In addition, when erecting a building on several floors, the installation of a frame support will be required. Despite some drawbacks, Sibit still outperforms other popular materials.

- The foam block contains artificial additives, and its shape does not always differ in ideal geometry. Autoclaved concrete is environmentally friendly and manufactured to exacting standards.

- Gas silicate is similar in composition, however, it is less resistant to frost and more expensive.

- Wood concrete is afraid of the cold and weighs more, it is not so convenient to work with it.

- The heat block has a lower thermal conductivity, in this it wins, but it has a dubious component in its composition - expanded polystyrene, and when handling it, extreme accuracy is needed so as not to spoil the material.

- Expanded clay concrete is stronger, but it needs additional insulation. Also, the blocks are smaller in size, so installation will take longer.

Sibit has many advantages over other materials. All this is achieved thanks to modern technologies.

How is it produced?

The secret of quality lies in strict adherence to proportions and production standards. As part of the mixture for the manufacture of aerated concrete, the following components are used:

- cement;

- sand;

- water;

- lime;

- aluminum powder.

The ingredients are crushed and ground thoroughly to remove all excess impurities, for example, sand processing can take up to 8 hours. After preparation, the dry components are placed in a special container, and then the bottom layer is poured with water and stirred until a creamy consistency. The solution is left for a while to allow it to harden.

The resulting blocks are cut to size and placed in an autoclave oven for 10 hours. Under the influence of strong pressure, concrete acquires increased strength and stability, its performance characteristics are improved when compared with a material obtained by natural hardening.

Quicklime is used as a binding component.

The substance is supplied in special closed containers to minimize interaction with air. When aluminum powder is added, a reaction occurs between it and lime, which leads to the formation of a porous concrete structure. The pore volume is approximately 3/4 of the total area of the block, which is why the material is lightweight.

For sawing, a machine method is used, which allows you to achieve ideal geometry. The cuts are smooth, and the dimensions exactly correspond to the specified parameters. Finished blocks are placed on pallets. After packing, the materials are transported to the warehouse. Depending on the size of the products, their number in the pallet and the total weight may be different, it is better to check this when purchasing.

Overview of block types

The gas block can be more durable, capable of withstanding a serious load, or designed for laying insulation. Also under the brand name "Sibit" are produced floor slabs, insulating panels and other types of products. All aerated concrete materials can be divided into three categories.

Heat insulating

They are used for additional insulation of walls or the construction of objects that do not experience significant loads during operation, for example, fences or small outbuildings. The density of blocks of this type can vary from D400 to D500.

Structural

They are used for the construction of load-bearing supports or for laying ceilings. They can withstand heavy weight and are highly durable. They are used to construct various buildings, both residential and industrial. The density of products in this category is from D900 to D1200.

Structural and thermal insulation

Combines the advantages of the two previous types. They are suitable for the construction of walls of residential buildings, while you can not use additional materials for insulation, since aerated concrete will retain heat well. You can also split products by item. The manufacturer's assortment includes:

- wall blocks;

- floor slabs;

- reinforced lintels;

- blocks for installing partitions;

- thermal insulation panels;

- additional elements.

In addition, on sale you can find related products, for example, glue for aerated concrete with the same name "Sibit". It is used as a masonry mortar, as well as for leveling surfaces.

There is also a winter version of the glue that allows you to work at temperatures down to -25 degrees.

Dimensions and weight

Depending on the type of product, the block sizes will differ:

- for wall models of category B2, the parameters are 600/200/250 mm, for B3 the width is 300 mm, for B4 - 400 mm;

- the smallest blocks for internal walls have indicators of 625/100/250 mm, for the largest ones, the width reaches 150 mm, other characteristics do not change;

- floors differ in length - from 2 to 6 meters, they can withstand a load of up to 800 kg.

A standard block with characteristics of 600/200/300 mm weighs 18 kg. At the same time, a similar volume of bricks (about 15-20 pieces) already gives 80 kg.

This is a noticeable difference that affects the speed of installation work, and one of the reasons for the popularity of Sibit in different areas.

Applications

Blocks are actively used for the construction of various objects:

- low-rise buildings;

- industrial building;

- warehouses and technical buildings;

- baths and garages;

- fences.

The material is in demand in private and industrial construction, it is suitable for the installation of load-bearing structures, wall insulation, laying of ceilings. Depending on the type of work, building blocks with a suitable density are selected.

Attractive cost and availability allow you to purchase a consignment of goods for private needs.

Usage Tips

Sibit is quite popular, so it is easy to find it in hardware stores. When buying, it is worth considering the following points:

- choose blocks that have a uniform color and structure, it is advisable to come to the base and look at the batch of goods with your own eyes, and not order remotely;

- ask the seller for a quality certificate to make sure that there is no fake in front of you - such a document in the store must be provided at the request of the buyer;

- make sure that the aerated concrete is well packed, do not purchase the product without a protective film, as it may be damaged during delivery.

It is not so difficult to properly lay the sibit with your own hands. Due to the lightness of aerated concrete, it is easier to work with it than with other materials. The installation speed also increases, large blocks are stacked much faster than small bricks.

You can build a house in a few months, and a small building, such as a bathhouse, will take even less time.

Transportation of aerated concrete does not require serious costs. The material is delivered to the site using a truck. Blocks can be transported across the territory on a utility wheelbarrow or carried manually. They have special holes-handles for convenience. It is important to be careful not to drop the items as they can break or crumble due to their fragile structure.

When building houses, baths and garages, standard wall blocks 200/300/600 mm are usually used. The volume of one such product is 0.036 m³, respectively, you can calculate the flow rate per 1 m3. The result is the number 27.78, which needs to be rounded to the nearest integer, as a result 28 blocks are required.

Products are shipped from the factory in pallets. Additionally, protective packaging is used so that the material is not damaged. When buying blocks, it is important to take into account how many pieces are in a pallet, this number can be different. For example, for a standard size of 200/300/600 mm, options are available for 25, 40 or 50 pieces.

Working with blocks will not cause problems, if you already have experience in laying bricks, the basic principles are about the same. Particular attention should be paid to the first row, it is important to accurately measure the angles, control the verticality using a plumb line or level. At the same time, there are certain nuances that are important precisely when laying a sibit.

Use a special adhesive. It is designed specifically for interaction with this material, therefore, when applied, it provides a strong adhesion between the elements. An exception can be made for the first row, since thermal insulation is pre-laid on the foundation, and the blocks can be safely attached to it using a conventional cement and sand mortar.

Process correctly. Sibit can be cut, sawed and planed, which allows you to quickly get additional elements right on the site using the tools at hand. But if you need to drill holes, choose a drill over a hammer drill, as it can crumble the porous structure of the material.

Observe order. After laying the first row, you need to wait a few hours and only then start with the second. The surface of the blocks should be treated with a special plane so that it becomes rough, then the glue will set better and the adhesion will increase. Reinforcement is performed when the fourth row is completed. Iron rods are placed in the cut grooves.

Choose the optimal temperature. It is best to do construction in a warm, but not hot time. The suitable range for work is from +5 to +25 degrees. If the temperature rises higher, the blocks will have to be moistened, and in winter it is necessary to use a special cold-resistant glue, otherwise the structure will not hold.

It should be borne in mind that buildings from sibit require finishing work - both external and internal. It is necessary to protect the material from moisture and other influences. It is important that the lining does not clog the pores of aerated concrete, it must breathe freely. For this, a small air gap is left between the facade layer and the wall.

Before applying the plaster, it is necessary to use a primer solution, as well as apply a reinforcing mesh, since the surface of aerated concrete itself does not have high adhesion. It is important to choose finishing materials that are suitable for working with a cellular base. In addition to plaster, protective paint can be used.

If you build a house from Sibit in compliance with all technologies, use high-quality finishing materials, then the structure can stand up to 100 years or more.

The basics of laying sibit on polyurethane glue in the video below.

The comment was sent successfully.