How to unscrew the screw?

The need to understand how to unscrew a screw arises even among experienced craftsmen who are faced with a break in the slot or other problems when removing fasteners. Such situations happen quite often when using a power tool, and when manually installing hardware. It is not always possible to fix the problem immediately. It is worth talking in more detail about how to properly unscrew a triangular and stuck screw, with a torn cross for a screwdriver and with lapped edges.

How to twist different types?

The main difference between different types of screw fasteners lies in the types of their splines and the shape of the caps. The rules for unscrewing are also different, since in each case you need to act in accordance with the characteristics of the hardware:

- Straight. Both large and very small can be easily unscrewed with a regular flat-blade screwdriver. The basic rule for working with such hardware is a tight fit of the tool tip. The slightest gap significantly increases the chances of a slot breaking.

- Cruciform, or Phillips. A distinctive feature is the ejection of the tool during screwing. This increases the likelihood of a breakdown. It is the cruciform variants that are the champions in unscrewing problems. When working with them, it is better to follow the non-screwing rule.

- Pozidriv... Cruciform with notches and parallel edges. This option does not have the problem of pushing out the tip of the tool, and more force can be applied during the final screwing of the fastener. Visually, Pozidriv differs from Phillips only in the presence of serifs. But the bits for them are different, like screwdrivers, otherwise the break of the slot will be inevitable.

- Hexagon. Internal slot in the form of a hexagonal recess in the screw head. For its correct tightening, the correct selection of a wrench or a screwdriver is important - the tool must sit tightly, without gaps. If there is an air gap, the tool tip will rotate, grinding the splines.

- Asterisk, or Torx. It appeared as an improved alternative to the hexagon. The screw withstands high tightening force and is centered. With the right choice of the bit, it will be quite difficult to rip it off.

- Three-beam... A variant considered vandal-proof due to its low prevalence. It comes in different shapes: Y-type, Ti-wing. In the first case, the slot looks like the letter of the same name, in the second - on the turbine blades.

- Vandal-proof TORX Plus... The slot of this screw is made in the form of a five-pointed star with a central pin. Vandalism is that only a special bit is used for installation, it is not included in the standard sets of tools. Do not unscrew the screw with other tools.

- Vandal-proof triangular slot (TA). It looks like a recess in the screw head, it can be turned not only with a special tool, but also with a hexagon or a slotted screwdriver of a small diameter. The probability of failure is low, the bat is easy to make yourself.

- One way. Screws with a straight head only. When trying to unscrew the screwdriver or bit, simply throw it out of the groove. It is impossible to turn it out in the usual ways.

- With external splines. To work with them, use a special tool with a recess that matches the shape and size of the mounting head. Available in square, pentagonal, hex, Torx, 12-point, or dodecad.Box wrenches are suitable for working with most of them; head licking occurs often when excessive force is applied during work.

These are the main types of screw fasteners that have problems with unscrewing. It is worth analyzing in more detail how to solve them.

How to remove problem screws?

Unscrewing a screw if its crosspiece is torn off is not an easy task. Licked hardware can be on a laptop or hold a car wheel, but there are still stuck and rusted bolts, options with a torn off head and with a left-hand thread. All of them are quite amenable to twisting, if you approach the matter correctly.

Tool change

If we are talking about ordinary screwdriver, its edges can be ground off in the course of previously performed work. If the contact is clearly poor, you should try changing the instrument. The one that fits snugly in the slot is selected. It is worth paying attention to the marking: for PH and PZ, screwdrivers with different types of tips are needed, they are not interchangeable.

The main rule: if the screw is too tight, you need to stop and stop ripping it off even more.

Using pliers

The method is relevant only if the screw head is located on the surface of the material, not sunk into it. The side parts of the cap are captured with pliers, counterclockwise rotation is performed. If the screw gives in, there is no need to rush - it is better to act slowly and carefully.

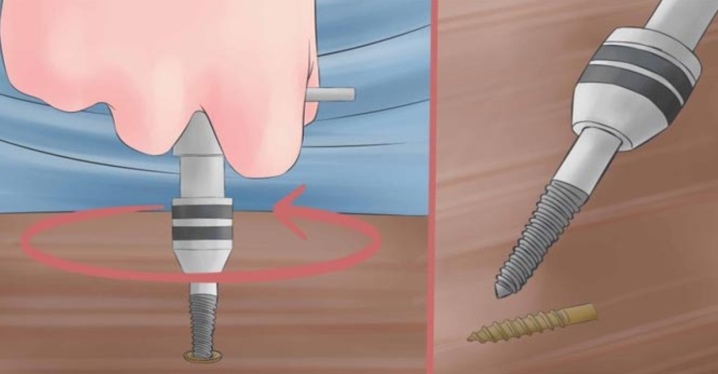

Power tool

If you cannot manually remove the jammed screw, you can try dismantling with a screwdriver or electric drill... To do this, the cartridge is freed from the bits, the hat is opened and fixed in it. It is important to remember that the power tool must have a reverse mode - it is in it that the work takes place. With a cap on the outside, this is the easiest way to remove the problem screw.

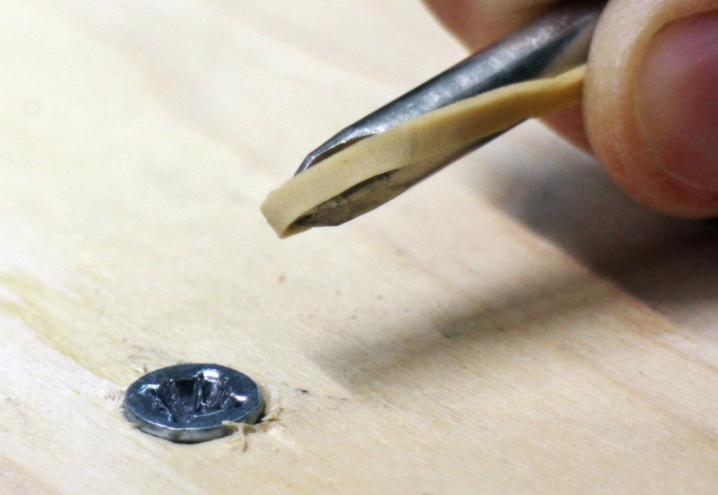

pad

With weak contact with a hat recessed deep into the material, it becomes too difficult to unscrew the problematic fasteners. The use of an additional layer between materials sometimes helps to solve the problem. For example, a piece of thin rubber, leather, or an abrasive part of a household sponge can be used for these purposes. The gasket is fixed over the head, improving grip, a screwdriver or screwdriver bit is inserted from above.

Notch formation

If the slot is torn off, you can unscrew the screw, making a notch on it with a grinder or a hand tool... Then, with a screwdriver of a suitable size with a flat tip, turning out fasteners. To further facilitate twisting will help short-term heating of hardware... Thermal expansion will help slightly increase the diameter of the hole, making it a looser fit.

Slicing faces

With an external type of torn slot, a simple solution can be cutting new faces on it. Processing is done with a file or grinder, a hacksaw for metal. Even 4 edges will allow you to use a wrench of a suitable diameter to get rid of a tightly seated screw.

Using a special tool

When other methods do not help, you can use the extractor by screwing it into the body of the fastener - this works even if the cap is blown off. Some of these devices require pre-drilling the hole. Extractor you need to wedge it in the screw, and then unscrew it along with the problem hardware. At the same time, the material is not damaged; this technology can be used on all types of fasteners, except for self-tapping screws made of hardened steel.

Cold and hot welding

A torn cap or lapped splines often do not solve the problem of removing the interfering screw. To regain control of the threaded connection, you can weld or glue the nut to its surface with a compound of the "cold welding" type... In this case, the screw can be removed using box or regular wrench.

Drilling

It allows you to completely remove a screw that is too deeply recessed. This method works with wood surfaces.... You can simply drill out the hardware itself, later replacing it with a new one. In addition, a good solution may be to use a cork nozzle that can pull out a solid section of the wooden surface along with its contents.

Soldering

A small screw or screw with torn off slots (most often cross-shaped) can be tightly connected to the screwdriver using soldering. To do this, hot tin is applied to the head of the fastener, and the tool tip is immersed in it. Let the compound cool and adhere well. Then you can easily unscrew the screw, which has become a continuation of the screwdriver, clean the tool from traces of solder.

Stuck and rusted screw

Here we also have to deal with the consequences of exploiting the connection. Remove rust it is possible with the help of special formulations, a few drops will be enough. Then used impact screwdriver (can be replaced with a chisel) and a hammer. Under shock loading, the stuck and rusted parts of the screw become movable. Once they give in, you can change the tool and unscrew the problematic threaded element in the traditional way.

Knowing what to do, if the screw head does not unscrew or has completely fallen off, you can unscrew almost any problem hardware. It is enough to be patient and act carefully. Then it will be quite easy to unscrew even a screw with torn off edges for a Phillips screwdriver.

Recommendations

A tool useful for unscrewing different types of screws is best purchased in advance and kept close at hand. This moment is especially relevant for owners of garages and personal vehicles. Here an extractor for unscrewing broken hardware will be as useful as possible - it is better to choose a universal type of construction, with a shortened working part. With it, it will be possible to unscrew the problematic fasteners even in hard-to-reach places.

There are some simple tips to help you reduce the chances of edges or splines breaking off.

- Select exceptionally high quality fasteners with a hardened head.

- Securely fix the tool tip in the slots. When a screwdriver or bits slip, the protruding edges are erased - it will be more difficult to turn out such a hardware.

- Maintain the tool in working order. On a key or screwdriver, the edges also often turn out to be licked, which greatly interferes with the normal unscrewing of the fasteners.

Considering these tips, you can avoid the occurrence of problems with unscrewing screws for various purposes from the parts fastened by them.

In the next video, you will learn how to remove any screw.

The comment was sent successfully.