What are nuts and what are they like?

When carrying out various construction work, a large number of all kinds of fasteners are used, including nuts. They can be made in a variety of ways. Such fasteners are most often made from a plastic or metal base. Today we will talk about the features of these products, their main varieties and characteristics.

What it is?

Products are fasteners with threaded holes. They make it possible to make a collapsible connection using a stud, screw or bolt. Also, parts of this type have a special structural part for the transmission of torque.

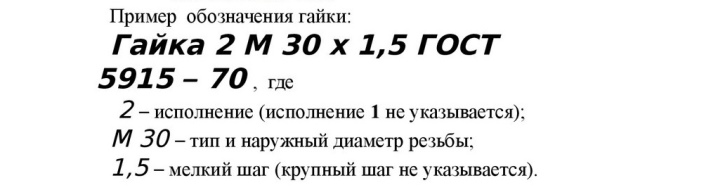

All nuts have their own marking, which also reflects the strength class.

Each model of such fasteners can only have strictly defined dimensional values, which are indicated in the relevant GOST standards.

These fasteners are widely used in various fields. First of all, they are used for a variety of mechanical assembly works, in the automotive industry. In the manufacturing process, parts are often covered with special protective compounds, which will significantly improve their properties and form a more reliable and durable connection.

How are they different from washers?

First of all, the nut will differ from a simple washer in that it has a threaded surface in the inner part, therefore the element is used to fasten different parts, the washer acts as a gasket or insulation.

Also, the nuts always have edges from the outside, they are a stop for the key. There are no edges on the insert, it usually has a simple, smooth outer part. The first part is most often made of metal, the second is made of metal, rubber, and plastic.

Species overview

There is a huge variety of these fasteners. Let's consider some of them separately.

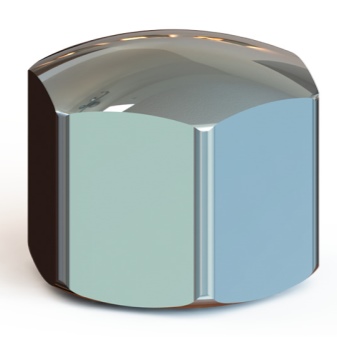

Hexagonal

These models are considered the most popular.

To tighten such a part, you will need special wrenches.

The side faces of fasteners are considered to be the main structural element that affects the torque as well as the fixing of structural components at the attachment points.

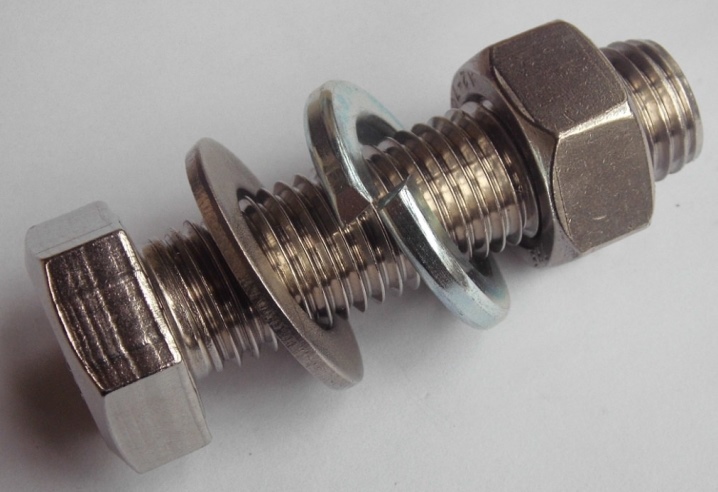

In the same set with such hex samples, as a rule, there are different types of screws, bolts or threaded studs. Together with the nut, these products form a strong and durable connection.

Washers of different thicknesses and diameters can sometimes be used to provide additional sealing.

Hexagonal variants are most often made from various types of high-quality steel, since this material is the most durable, reliable and hard. In some cases, plastic samples are also used. They should be used when joining structures that are not intended to withstand excessive loads.

Models of this type can be divided into several distinct varieties. The main characteristics and requirements for the production of nuts can be found in the DIN 934 standard.

Crowned

These types of nuts have slots on the top. Such fasteners are used to form connections in critical areas.

They are primarily intended to prevent self-unrolling.

Crowned specimens look like regular hexagons. But at the same time, they have vertically sawed slots. These varieties are particularly difficult to manufacture.

The main regulatory document according to which the production of castellated and low slotted nuts is carried out is GOST 5918-73. The European standard DIN 935 is also used. Fasteners of this type are distinguished by an increased level of strength. Most often they are produced in two versions: low and regular.

Crown models are screwed onto bolts, studs or screws that correspond to their dimensional values. They are predominantly manufactured from carbon steel and stainless steel.

Often a special zinc coating is applied to their surface.

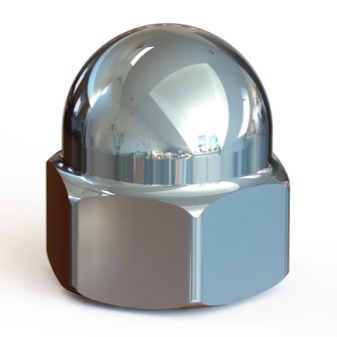

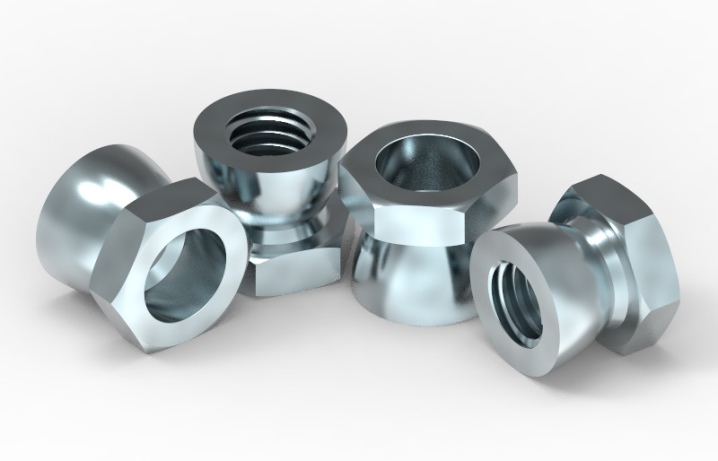

Caps

Such varieties are taken in cases where it is necessary to make a neat and reliable threaded connection. They are metal products equipped with a special spherical cap.

These nuts are considered decorative.

If necessary, paint can be applied to their surface.

During the manufacturing process, products undergo thorough processing, due to which they acquire special resistance to corrosion.

The spherical cap allows you to completely close all burrs and other irregularities. GOST 11860-85 assumes two designs of cap parts: spherical and flatter. They will differ in the depth of the cap. The second option will require the most accurate adjustment of the length of the bolts.

Cap nuts are rarely installed together with washers, because the load on the finished joint is usually minimal, so there is no need to use additional elements.

Such fasteners can be made of stainless steel, carbon steel, alloy steel, brass base, galvanized metals. But you can also find models made of durable plastic, such options should be used when creating various pieces of furniture.

These models are used for a standard hexagon. Such deaf varieties help to form the strongest and most durable joints of various materials.

Square

Samples of this type are also screwed onto studs, screws or bolts. They are distinguished by a non-standard head shape that allows you to securely hold fasteners without the use of tools.

Square specimens should be used in cases where it is necessary to create the most durable and reliable connection of the structure. These cage fasteners, compared to standard hex types, have a larger surface, which necessarily comes into contact with the part to be fixed, which provides maximum resistance to loosening.

Most often, square nuts are fixed together with flat washers to prevent sharp edges from damaging them and significantly increase the level of strength and reliability. These varieties can have fine, medium or coarse threads. Often it is additionally covered with a layer of yellow or transparent zinc.

Square specimens are fairly easy to fix. In addition, it will be convenient to work with them in a confined space.

To secure them, you can use not only wrenches, but also pliers.

Wing nuts

These types of nuts are used to create strong connections without the need for tools. Fasteners of this kind are elements with two petals on the top.

They act as supports when the fastener is tightened or unscrewed.

Wing nuts are most often made from high quality and durable stainless steel. They can be attached together with washers and pins, allowing you to provide the most durable and strong connection of materials.

These fasteners are constructed from brass, cast iron and steel. They can be produced both by forging and by casting. The products are mainly used in shipbuilding, car assembly, submarines. They will be able to retain all their properties and appearance even with constant contact with water or with aggressive chemical components. Varieties with slightly rounded ears are called German. Models in which they have a rectangular shape are called American.

With flange

These instances look like a simple hex nut with a slight expansion on the bottom. Moreover, it may have special notches that prevent parts from loosening. Flanged models are generally available in stainless steel or carbon steel.

Flanged specimens can be made with or without a protective coating. In the first variant, most often the surface is subjected to galvanic treatment, during which it is covered with a thin layer of zinc. It provides, among other things, the special resistance of the material to the formation of corrosion.

The use of flange nuts greatly speeds up the assembly of various designs, because it does not take time to fix the washer.

The diameter of the flange must be larger than the diameter of the fastener itself.

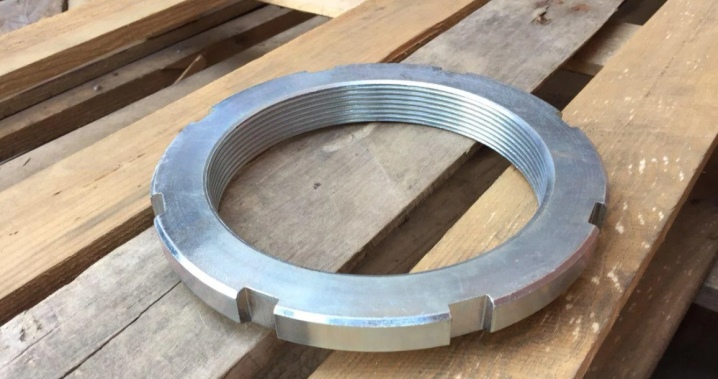

Slotted

Slotted fasteners are a metal ring. At the same time, a thread is applied to the inner hole, and special slots are applied to the outer surface, which are formed using a router. These products for connecting structures are fixed with a wrench of the appropriate size.

These nuts are widely used in a wide variety of industries. Most often they are used to work with couplings, bearings. Fasteners can easily withstand significant weight loads.

Slotted samples can be used even in aggressive environments.

For their manufacture, brass or stainless steel is taken. They can be coated with special protective compounds: nickel plating or zinc plating.

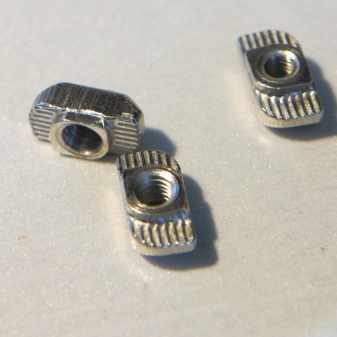

Embedded T-shaped

These specimens should be used when working with wood. They will allow you to reliably hold the workpieces in the machine during their processing. The base of such models has a simple round shape. The fasteners also have a threaded part inside.

Hidden

These instances are installed directly inside the structure. This mount is particularly durable and durable. Secret varieties are more often used when creating pieces of furniture, fastening sheet materials. These nuts have a cylindrical shape, there is a threaded element in their inner part.

Conical

Such models have the form of a tapered fastener, on the inside of which a thread with a spiral is applied. On the other hand, the part can be made both closed and open.

Tapered elements are often fully hand-tightened.

They have found their wide application in mechanical engineering. Fasteners are created from various types of steel. Special protective coatings are applied to their surface, which allow the use of ready-made compounds in conditions of high humidity or in an aggressive environment.

Presser

These nuts are used for the grinder, they provide a secure fixation of the grinding wheel.

Special quick-clamping specimens are also distinguished separately. The latter are made from the hardest and highest quality types of steel, they help to remove working wheels with just one movement of the hand.

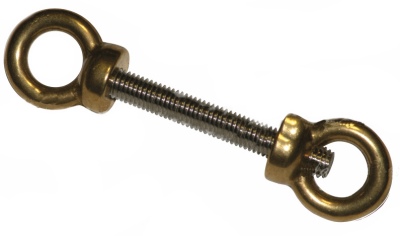

Eye nuts

These instances are created with a threaded through hole (inch or metric). A rod-type fastener is screwed into it, due to which the strongest fixation is obtained.

Eye nuts differ in that their threaded part is located at right angles to the plane of the metal ring.

This feature makes it possible to twist the part using a lever.

Often these nuts are combined with eyebolts. Such products will make it easy to withstand the heaviest loads. As a rule, for the production of such elements, carbon steel is taken, which has increased resistance to temperature extremes and moisture.

Press fit

The press-fit model is also called press nut. Such instances are used to work with metal sheet material. Outwardly, they resemble simple fasteners, but at the same time it is supplied with a small projection in the form of an inverse cone with a ring.

Such products are also equipped with small teeth that prevent the part from loosening. Some varieties are performed with floating teeth.

Special anti-vandal fasteners should be noted separately. They look like a part with an internal threaded thread and a special hole in the head. Some of them are made with a non-standard configuration that prevents the part from loosening.

The vandal-proof version can be fixed with keys and screwdrivers. Parts are often used in elevators, entrances, and transport. These products should be made from the strongest and most durable types of steel.

Separately, it should be said about special riveting nuts. These fasteners are very similar in appearance to simple rivets, but at the same time they are characterized by an internal threaded part. The specimens are widely used in industrial construction.

To install the nut, you will have to use a powerful hand drill with a movable type metric hairpin.

Special welded nuts are permanently fixed to the structure, after which a bolt is also screwed in there. This option is ideal for thin walls that will not allow a threaded bolt hole.

All of the above varieties can be divided into two large groups: inch and metric. In the first option, the diameters of the fasteners will be indicated in inches, in the second case - in millimeters.

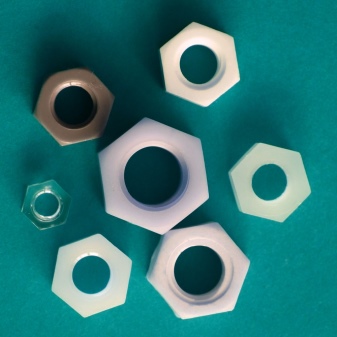

Materials (edit)

These fasteners are made from different materials.

- Steel. When creating them, stainless, carbon, alloy steel is used. This metal is characterized by high strength, hardness, density, corrosion resistance, as well as heat resistance and heat resistance. Steel materials lend themselves well to cutting and processing. They also differ in weldability, which ultimately allows you to get the most reliable connection.

- Brass. This metal also has good resistance to corrosion, aggressive environment, water. Brass alloys are fairly easy to machine and have good strength and density. In addition, these metal substrates are often made with additional additions of iron, tin and nickel.

- Plastic. Compared to the two previous options, plastic nuts are much less durable, so they should only be used for structures that will not be subject to high pressure and weight loads.

- Copper. This option is not often used to create nut fasteners. Copper bases cannot boast of sufficient strength and hardness. But at the same time, they practically do not corrode. Copper is characterized by a high degree of ductility. This material should be used in the manufacture of decorative fasteners.

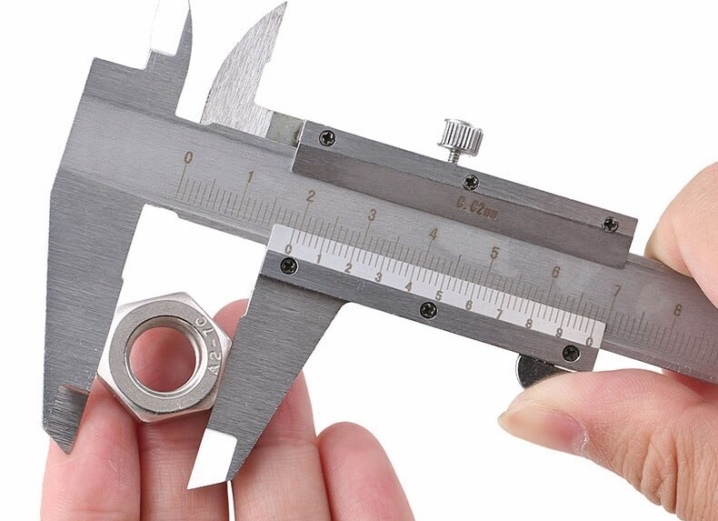

Dimensions and weight

These values are indicated on the product labeling. They must correspond to the values according to GOST. The size of the nut is the distance between two parallel faces.

The most common are samples with dimensions of 10, 12, 14, 16, 18, 20 mm. The weight of fasteners can also vary significantly depending on the material from which they are created, the size, and the type of protective coating.

It should be remembered that high-strength varieties have a higher mass compared to simple models.

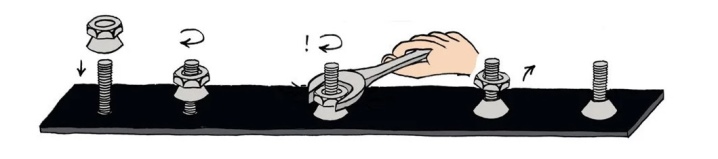

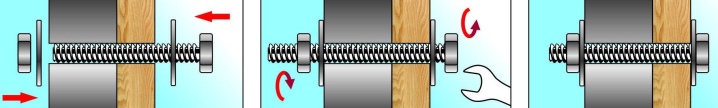

How to tighten correctly?

In order for the connection to be as reliable and durable as possible, the fasteners should be tightened correctly. To do this, prepare all the necessary tools with which the parts begin to gradually tighten.

In this case, at the moment of tightening, you will need to ensure that you do not overdo it. Otherwise, this can lead to the fact that the finished connection will lose its integrity and will soon break.

The technique for fixing nuts may differ depending on the specific type of fastener.

How to unscrew quickly?

To remove the old nut, you can use the same tools with which they are installed. They gradually unscrew the products from the structure.

If the junction is rusted, then first it is necessary to treat this area with a special solvent, sometimes brake fluid, table vinegar, carburetor cleaner or kerosene are used.

You can also use the heating method, in which case you will need a gas torch, lighter or blowtorch. As a last resort, just boiling water will help. At the same time, the nut is very hot, and then they try to unscrew it with a wrench.

The comment was sent successfully.