How to choose the right crushed stone for the foundation: criteria and recommendations

The basis of any house is a foundation, for which you should choose the highest quality building materials, if possible. One of the constituent components of the foundation is crushed stone. It is his choice that determines the strength and durability of the future structure (house), in addition, high-quality building materials allow you to avoid additional considerable costs, since you do not have to change and fix something during construction. To make the right choice, you need to understand all types of crushed stone and understand which grade and for what purposes is ideal.

Peculiarities

Crushed stone is one of the most common fillers for concrete mix, without which no modern building of a house or other object can do. This building material has many classifications and is endowed with different characteristics and features, which directly affect the quality of the future construction, and the strength of concrete, and the strength of the foundation. Despite the low cost as for a building material, crushed stone combines all the qualities that are irreplaceable in construction.

Crushed stone has the following features:

- high degree of strength - when compared with all fillers for concrete mix, the most durable of all types of crushed stone is granite material;

- moisture resistance - crushed stone does not react at all to moisture;

- excellent tolerance to temperature extremes - frost and heat, as well as resistance to environmental influences. Crushed stone is able to withstand up to three hundred changes in temperature cycles;

- high adhesion - due to the rough surface and acute-angled shape, the adhesion of the material to concrete is significantly enhanced;

- reduction of settlement and creep of concrete, which minimizes the occurrence of cracks and all sorts of deformations in the constructed building;

- ease of use;

- high performance properties.

In addition, due to the variety of types of crushed stone, you can always choose the one that is suitable not only in terms of technical characteristics, but also in terms of cost.

High-quality crushed stone must be selected based on the following technical characteristics:

- Flakiness is a characteristic of the flatness of a material. In total, crushed stone has 4 categories of flakiness: rounded, cuboid, improved and ordinary;

- degree of strength - the stronger the material, the better. The highest indicators of strength are endowed with two types of crushed stone: granite and gravel;

- radioactivity is an important characteristic that depends on the deposit of building material. High quality crushed stone is certified for radioactivity. This indicator does not affect the strength of the material, however, the level of environmental friendliness depends on it;

- frost resistance - this characteristic indicates the number of seasons that the foundation of this material will withstand. According to the level of frost resistance, crushed stone can be divided into stable, unstable and highly resistant;

- compaction coefficient - the density of crushed stone ranges from 1.2 to 3 g / cm³. This factor depends on the type of origin of the material. Crushed stone with a high degree of density is versatile and has an unlimited scope. The density and strength of this building material are directly proportional.

Views

Crushed stone for the foundation is divided into types by fractions, as well as by purpose.

By the nature of origin, this building material is divided into many types, among which it should be noted such as:

- granite;

- gravel;

- limestone;

- secondary;

- slag.

Each of the above types has its own characteristics, features and purpose, which is the decisive factor when choosing a particular type of material.

Granite

Granite crushed stone is a building loose and granular material of inorganic origin. The grains of crushed stone are quite large - from 5 mm and more, which are mined by crushing granite. Such crushed stone has excellent technical characteristics, which makes it a popular building material in various processes. It is a good aggregate for high quality concrete. Most often, it is found in a reddish or grayish hue, since it contains mica, feldspar and quartz. Granite crushed stone is the most expensive, as it can withstand enormous loads, has excellent adhesion to concrete, is resistant to temperature extremes and is endowed with high strength.

This building material is divided into such fractions as:

- 5–10 mm - used in the production of concrete, reinforced concrete products, asphalt, as well as for decorative purposes;

- 5–20 mm is one of the most demanded fractions in the manufacture of asphalt and concrete. In addition, it is used when pouring the foundations of a residential building, bridge structures, bridge sheets, as well as for decorative purposes;

- 10–20 mm - used in the production of concrete, reinforced concrete products, when laying foundations, when pouring structures for the construction of bridges;

- 20–40 mm - with the help of this fraction, crushed stone is used to fill sites, roads, and also make pillows for the base of the foundation and are used for decorative purposes;

- 25–60 mm - most often used in the construction of railways, a ballast layer is made. In addition, it is perfect for backfilling roads and sites, as well as in decorative projects;

- 70–150 mm - this fraction of crushed granite is irreplaceable in places with fluid soil and huge loads on dump sites;

- 0–0.5 mm is the screening used as a decorative material during finishing work. In addition, it is suitable for bedding paths, playgrounds and sports areas.

Crushed granite has a lot of advantages and only the only drawback is the high price segment.

Gravel

Crushed gravel is a non-metallic, free-flowing material that is obtained by crushing or screening quarry (rock) rocks. It is frost-resistant, however, its strength is somewhat lower than that of crushed granite, but this does not prevent its use in many types of construction work. Crushed gravel is divided into two types: sea and river. The huge advantage of gravel is its low radioactivity and ability to absorb radiation, which is why it is quite popular. Due to its affordable cost, this type of crushed stone is widely used in the construction of residential buildings, roads, in the production of concrete, reinforced concrete products. This material has a medium density, low flakiness, which allows to achieve good shrinkage and tamping in the manufacture of a building mixture, and also has a good cultivation capacity. In addition, crushed stone has a low percentage of impurities and dust, which does not exceed 0.6.

The material has such fractions as:

- 0–0.5 mm is a gravel screening that can be used in landscaping and for sprinkling roads;

- 3–10 mm is a fine fraction, which is widely used for pouring floors and for laying foundations;

- 5–10 mm is a rather demanded fraction that can be used in the production of concrete for a foundation;

- 20–40 mm is the middle fraction. This type of crushed stone is needed for the manufacture of concrete for the foundation, as well as for drainage work;

- 40–70 mm is a coarse fraction that is used during road repair works, for drainage works, for concreting and strengthening of various structures.

Crushed gravel is an excellent choice when laying the foundation of a private residential building.

Limestone

Limestone (dolomite) crushed stone is a hard natural building bulk material, which is obtained by mechanical crushing of rocks in quarries. Further, the resulting material is carefully sieved and divided into fractions used in various industries. Most often, such crushed stone is found in white, but sometimes it comes across both light yellow and gray. The color of the material depends on the presence of impurities in the rubble (iron oxide, quartz and clay). This building material has excellent technical characteristics: low level of radioactivity and high strength.

According to the flakiness, limestone crushed stone is divided into three classes, such as:

- cuboid;

- ordinary;

- improved.

In addition, due to the unique molecular structure, crushed limestone has a high degree of frost resistance. It can withstand even record low temperatures. By dividing the material into five fractions, it is used in the production of concrete, building mixtures, road surfaces, foundations for garages, storerooms, summer buildings, as well as for mechanical filtration of water in industrial tanks.

Secondary

Secondary crushed stone - this type of crushed stone is obtained by crushing and processing bricks, asphalt, fragments of reinforced concrete structures and other construction waste, that is, construction waste turns into useful material. It is used as a bedding for sidewalks, concrete platforms and floors, but it is not suitable for a foundation under a building, since it is not endowed with all the technical characteristics.

Slag

Slag (cast) crushed stone is obtained by processing dump or steel-making slag. This is a fairly inexpensive building material, and since it has a specific composition, it can be used in the production of heat-resistant concrete and mineral wool. As a base, it is suitable for houses with a small area.

The size

The list of the main characteristics of crushed stone also includes its fraction - the size of the stones. The possibility of its use in construction work depends on the fraction of crushed stone.

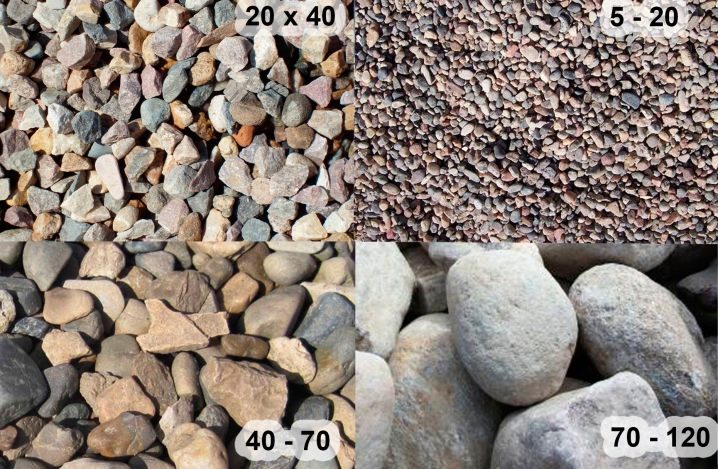

So, crushed stone is divided into three main fractions, such as:

- small - belongs to the material of the following sizes: 3x8, 5x10, 10x20, 5x20 mm;

- medium - crushed stone with dimensions of 20x40, 25x60 mm;

- large - presented in sizes 20x70 and 40x70 mm.

In addition, there are non-standard sizes of crushed stone, but they are not used as a building material, they are used in decorative and landscape works.

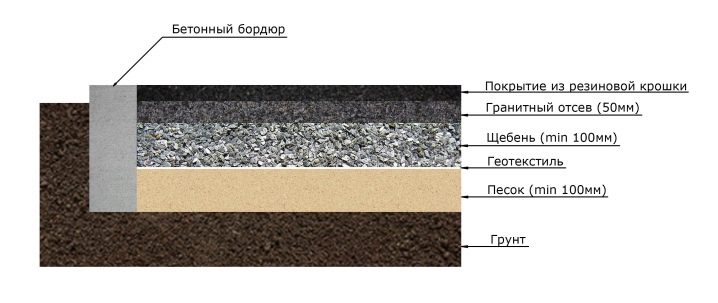

Filling device

Before laying the foundation for the house, many actions are performed that precede a serious process, the so-called preparation. In this case, it is necessary to comply with all norms and rules so that in the future you do not get distortions of window and door frames, the appearance of cracks on the walls and drafts. The key to a high-quality foundation is bedding.

For its implementation, it is necessary to use high-quality building materials that have the following features:

- are not heaving;

- do not lose their properties with temperature drops;

- perform drainage functions during compaction;

- do not contain flammable impurities.

As a rule, the bedding (pillow) is made from a construction mixture, which includes concrete, sand, crushed stone. The thickness of such a pillow can be from 25 cm to 60 cm. The bedding can be sand, or it can be made of rubble. The sand option is budgetary and quite common.

The technology for erecting a crushed stone lining (pillow) should be carried out, observing the following steps:

- A trench is pulled out, the bottom of which is covered with fine crushed stone or coarse river sand. The layer should be 10-15 cm;

- further, there is a layer of crushed stone. According to SNiP, compacted gravel or a thin layer of concrete is needed, in which the cement is at least five percent. The thickness of such a layer is 20–25 cm;

- crushed stone is well leveled and compacted with a vibratory saw. All free space must be eliminated.The filling of crushed stone should reach the level of the edge of the trench. It is from this mark that the countdown of the foundation will begin.

A sand pillow is the best option for people who are constrained in the funds provided for the foundation. It is made using coarse sand. Before backfilling, it is necessary to cover the bottom of the trench with roofing material or geotextile to prevent mixing of sand with the soil. In this procedure, tight compaction is also important, which can be easily done with a roller. After careful preparation and creation of the cushion, the foundation slab is laid.

Advice

When buying materials for laying the foundation of a house or other construction work, you should take into account all the technical characteristics of crushed stone and choose it strictly for the intended purpose. For the foundation of a residential building, crushed stone with a fraction of 20–40 mm of cube-like flakiness is optimal, and for a summer kitchen, a gazebo or a bathhouse, crushed stone of a smaller caliber - 5–10 mm is suitable, even crushed lime is allowed. You need to choose the material taking into account your expectations, material capabilities and the advice of the master.

In addition, in the process of building a foundation, you need to pay attention to the following tips:

- it is necessary to take into account the established requirements regarding the ratio of the crushed stone fraction to the type of future structure;

- do not allow any dirt on the gravel;

- remember that the concrete must completely encircle the rubble;

- the grade of crushed stone should be higher than the grade of the solution itself.

If you have doubts when choosing a building material or you do not have enough skills and knowledge when pouring a foundation, then it is better to contact a specialist and get expert advice or assistance.

For information on how to choose the right crushed stone for the foundation, see the next video.

The comment was sent successfully.