All about plywood boxes

Plywood boxes are a familiar, but at the same time, almost irreplaceable thing. These versatile boxes can be used in many areas of life. If there is a need for plywood boxes, then it is not necessary to immediately run to the market, you can try to make them yourself.

Description

Plywood boxes can be made from different types of wood, often birch, linden or pine. The box body is made from edged boards, and their covers are made of plywood, chipboard. The dimensions of this product may vary, therefore, if necessary, manufacturers can add stiffening ribs, consisting of 12, 16, 24 strips.

The thickness and configuration of the parts of the box is influenced by the purpose and weight of the cargo that will be stored in it.

The production of plywood boxes is regulated by GOSTs. These products are characterized by the following advantages:

- low cost of material;

- good performance;

- low weight;

- environmental safety.

In addition to the above features, plywood can withstand all kinds of treatments, and the application of various inscriptions is no exception. Boxes of this type are quite durable and capable of transferring moisture, even if the product gets wet, it will not lose its operational capabilities. Plywood boxes have a well thought-out design, so they can be quickly disassembled and assembled. Since the boxes are lightweight, the transportation of goods in them is characterized by a low cost. Despite the lightness, plywood boxes are very reliable and preserve the integrity of the products that are in them.

Plywood products also have disadvantages, such as a high combustion rate. Also, if wet and not dried, such boxes can swell and become moldy.

Therefore, the owners of the boxes should remember that the latter need ventilation and drying.

What are they?

Depending on the purpose, the plywood box can have a different design. This type of container can be with or without a lid, retractable, high, folding, collapsible, with a pencil case or a lock. But there are the most common types of plywood products.

- Folding box. The box is characterized by the principle of fastening the side walls to the bottom. The connection of structural elements is carried out using awnings.

- Box - the packaging is quite simple. The sides are attached to each other with nails and self-tapping screws. These products are used for transportation purposes, which is facilitated by the compactness of dimensions, namely 50 by 40 cm.

- Decorative box. Such a box is characterized by slotted fasteners.

Appointment

Plywood boxes have found their use in household needs, as well as during the transport of goods. Such a container is quite popular nowadays; it can have the following purpose:

- general;

- for vegetables;

- for little things;

- for flowers;

- for tools;

- for postal deliveries;

- gift.

Valuable and fragile cargo is transported in plywood boxes. In addition to shipping boxes, decorative plywood boxes are in great demand, for example, for wrapping gifts for February 23rd. This type of container is also used for CNC, as well as for the manufacture of the bottom of furniture.

Manufacturing

Making plywood boxes with your own hands is not difficult. First of all, the master should decide on the type of container and its dimensions.

Materials and tools

Before proceeding to the main stage of making a box from thin plywood or wood, you need to select the dimensions and thickness of the workpiece, and, if necessary, make a drawing.

Since wood canvases can be formed from different types of wood, their properties can also vary.

- Birch. This material is currently considered the most common. The use of this type of wood guarantees the originality of the pattern, as well as a smooth base.

- Pine. Pine wood is very dense and strong, as well as resistant to mechanical stress.

- Linden. Linden base for drawers contributes to the flexibility and strength of the products.

In order for self-made boxes to be of high quality and last a long time, craftsmen should use wooden sheets of different thicknesses.

For the bottom, it is worth taking plywood with a large thickness, and thinner for the side walls and roof.

Before proceeding with the direct construction of the box, the master should prepare the tools, which are indispensable in this work. It is worth stocking up on the following devices:

- jigsaw;

- woodworking machine;

- drill or screwdriver;

- furniture stapler.

In addition, when assembling containers, you cannot do without wood glue, sandpaper, building corners, a pencil, small nails, masking tape.

Fittings

Accessories are parts and particles for auxiliary purposes, with the help of which you can create a solid product. Also, packaging devices are needed to strengthen all kinds of boxes. Thanks to the fittings, the boxes ensure the safety of the goods.

Among the most popular products for creating plywood boxes are the following:

- tapes for strengthening boxes;

- handles with different sizes;

- hinges, latches, ears;

- corners, transport pockets, fittings;

- ventilation grates;

- drain nets;

- hardware;

- welded structural elements.

Also, if necessary, rollover sensors are mounted on plywood boxes. They aid in tracking box tilts and overturns.

How to do it?

Every person who has a great desire can make a plywood box with his own hands. During the manufacture of containers, it is worth observing consistency and accuracy. To increase the service life of the box, it is worth remembering the following rules:

- make the bottom of a material with high strength;

- the walls can be made thinner than the bottom, but excessive savings in this case are not welcome;

- it is not necessary to make a lid, its creation is required only if it is provided for by the peculiarities of using the box;

- pens can be bought in a store or made by yourself;

- if desired, the box can be decorated with decorative elements and fittings.

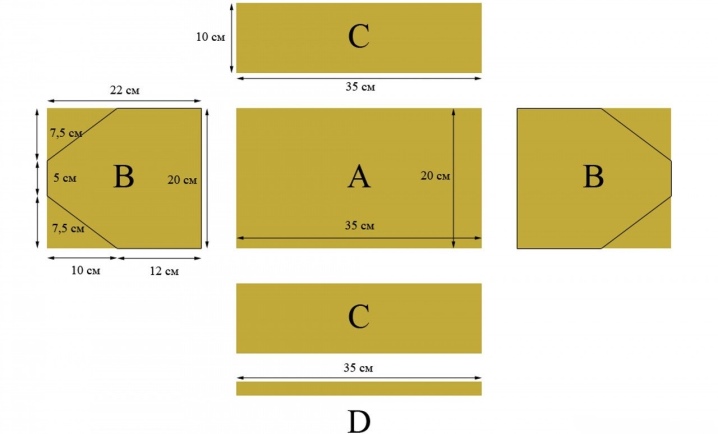

In order to avoid mistakes during the assembly process, experts recommend making a diagram with real measurements in advance.

Assembly

After the drawing and all materials are prepared, the master can proceed to assembling the box. In order to make a homemade container, you will need to complete certain steps in stages.

- Pre-approved measurements are transferred to plywood sheets. For this work, it is worth using a simple pencil and making them thin lines that can be easily erased.

- Saw out the main parts. The procedure should be carried out carefully in accordance with the lines.

- They make grooves that contribute to the solidity of the future box. At this stage, you can use a jigsaw or a standard hacksaw.

- The finished container parts must be processed with the necessary tools and sandpaper. In this case, a grinding machine will come in handy, which will help reduce the time and effort of the master.

- You can begin to fasten the prepared parts of the structure, start applying construction glue to each of the joints and grooves.

- To dry the box, it is determined in a dry and warm room for about 4-6 hours.

- The dried plywood parts of the box are connected together with self-tapping screws.

If necessary, fix the handles, you need to drill holes. The fittings are fastened with furniture bolts.

Experts do not recommend using self-tapping screws, as they can cause the structure to loosen after a while.

Sometimes craftsmen install small wheels on plywood containers, thanks to which the movement of the box becomes more comfortable. You can use a regular furniture bolt to attach the wheels.

The assembly of the mailbox takes place a little differently, since it has a roof. For its manufacture, parts are cut out and attached to a box for a couple of decorative awnings. The toolbox has a handle that is formed from a handle. Screw the part with a long self-tapping screw through the side wall.

Decor

Before you start using plywood containers, it should be processed in order to level the surface and fill up the excess holes with wood putty. It is characterized by quick application and drying. After the putty has dried, the master can begin to varnish the surface of the box.

Using varnish, you can achieve a more attractive appearance of the box, as well as its protection from temperature extremes and high levels of humidity.

Decor elements, which have a rack-like appearance, are fixed to the container using construction glue. If self-tapping screws or bolts are used in the work, this can lead to a violation of the aesthetic appearance, making the box rough. The outside of the box can be painted in any color using acrylic paints.

It is not difficult to make a plywood box with your own hands, provided there is a great desire, as well as tools. This type of work is characterized by simplicity, speed and minimal financial costs. It is recommended to form external walls with a jigsaw. To avoid the accumulation of unpleasant odors in the plywood box, holes are made in the bottom for ventilation. Cutting them out should be neat and at the same time chaotic or symmetrical.

High-quality plywood packaging can become a worthy alternative to a wooden product, since its performance is no worse. Some of the disadvantages of a plywood box can be easily compensated for by its minimal cost. This type of container can be made by hand, not only in accordance with standard sizes, but also by individual measurements. If there are a lot of small items in the house and there is nowhere to store them, then a simple and affordable plywood box can solve the problem.

How to make a plywood box with your own hands, see the next video.

The comment was sent successfully.