Features and varieties of moisture resistant plywood

In the construction market, plywood is very popular, which is dictated by the possibility of its use almost everywhere. For joining the wood veneer sheets, synthetic veneers are used, which provide some degree of protection against moisture. However, there are also certain species on the market that are more protective and can cope with the effects of water.

What it is?

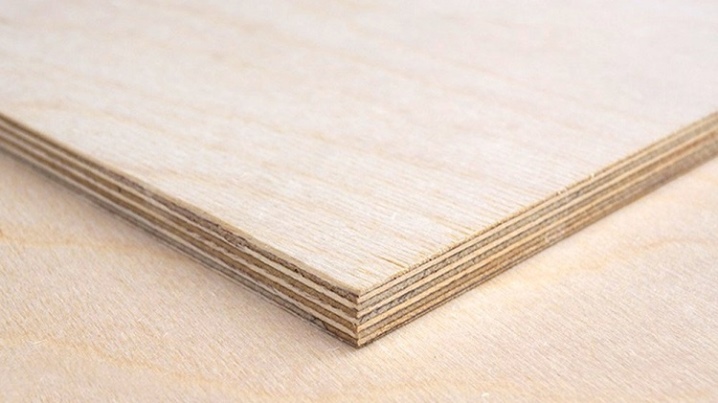

A distinctive feature of moisture-resistant plywood is that special substances are used for its production. It is these components that provide reliable protection of the material from moisture. In most cases, manufacturers use drying oil to impregnate wood, and a special paint and varnish coating can also be used. Even at the stage of forming the slabs, a certain level of resistance to moisture is set. This is done by adjusting the composition of the resins that are needed to connect the layers. Therefore, an experienced specialist only needs to look at the composition of synthetic resins in order to understand the degree of plywood resistance to water.

This manufacturing method makes plywood durable and maximally resistant to deformation. This can be achieved thanks to the presence of many layers, as well as special adhesives.

The main advantages of this material can be highlighted.

- High level of resistance to moisture. Such plywood will not deteriorate due to the influence of water. In addition, it does not stick to layers and does not lose its shape.

- Ease of processing. Despite the fact that the material boasts high strength, it is quite simple to process it. You can change the shape or mount plywood using various tools.

- The ability to combine with other building materials. A distinctive feature of this type of plywood is that it is very often used as an additional coating. This is possible due to the fact that it can be combined with natural or polymer components without any problems.

- Wear resistance (BS). Such plywood is able to cope with enormous mechanical stress, and the integrity will not be compromised. That is why the material retains its attractive appearance even after years of use.

- Resistance to temperature extremes, which allows you to install it even in the bathroom.

- Affordable cost. Plates of such plywood are several times cheaper than wood. In addition, there is always an opportunity to save money by choosing a material of lower quality and grade.

Comparison with other species

Moisture-resistant plywood has its own characteristics and advantages that distinguish it favorably from other options. Any plywood can be called moisture resistant to some extent, but only special waterproof options are able to cope with moisture for a long time. Among the main points that distinguish this material from others, it is possible to highlight its impregnation with drying oil, the presence of a special paint and varnish coating, as well as the possibility of including it in the composition of fiberglass.

On the modern market, waterproof plywood is presented, the thickness and dimensions of which can vary depending on the manufacturer.

In addition, each company offers products with a special degree of water resistance, which was achieved through the use of unique components.

It is the presence of these components that sets the material apart from others. Some of the most popular moisture-resistant components can be distinguished.

- Urea compounds, which guarantee maximum resistance to moisture, and also have an excellent effect on the strength characteristics of the product. In addition, such materials are not very expensive.

- Phenol-formaldehyde resins. They are characterized by extremely high efficiency, therefore, such plywood is often used for outdoor decoration.

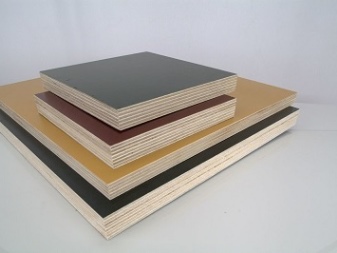

- Laminated boardswhich boast unsurpassed moisture resistance as well as the ability to withstand UV rays.

Standards

There are several standards of moisture-resistant plywood on the modern market, on the basis of which the types of this material are distinguished. Among the most popular and demanded are those presented below.

- General purpose plywood, which is a material that includes several glued veneer sheets. For the production of this material, coniferous varieties of trees are used. The production process is carried out in accordance with GOST 3916.1-96.

- Construction plywood, which is actively used in the process of construction and finishing works. This material is constructive, so no special requirements are imposed on it. In most cases, these are grade 3 and 4 plywood. For sizing raw materials, special adhesives made of phenol-formaldehyde resins are used. A distinctive feature of this plywood is usually impressive thickness, which is enough for almost any purpose.

- Furniture plywood, which boasts of its excellent external characteristics. Such products are not only distinguished by their resistance to moisture, but also cope with increased loads without problems. In addition, furniture options do not have any external defects, including chips or knots. In the process of processing, the material is well polished.

- Decorative moisture resistant plywood, which can be covered with various film materials. This option is also produced on the basis of GOST standards and may contain various options for synthetic resins.

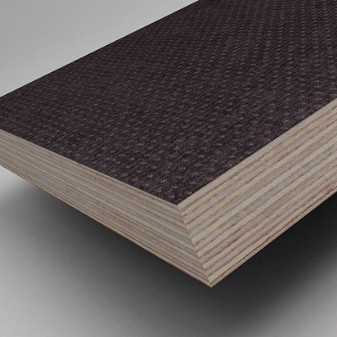

- Laminated plywood, which is characterized by its resistance to various environmental influences. That is why they are very often used to create surfaces with a high degree of wear resistance. A distinctive advantage of this material is its ease of installation and ease of processing. In addition, the surface is resistant to cleaning agents.

It should be noted that each type of moisture resistant plywood represents a specific standard that must be strictly followed during its production. All materials must have a special certificate of conformity, as well as marking with the designation of milestones.

Stamps

A huge number of plywoods are presented on the modern market, which differ in their classification. It is necessary to choose a certain type based on the brand that provides the degree of resistance of the product and exposure to water. There are several options among the brands presented on the market.

- FBA. These are sheet products, in the manufacturing process of which albuminocasein glue was used. Such a material cannot boast of a high degree of resistance to moisture, but it is quite safe from an environmental point of view and surpasses other brands by this criterion. Usually it is pressed or multi-layer plywood.

- FC. This material is made from birch veneer, such plywood is characterized by a high level of resistance to moisture.The unique features of the brand make it possible to use this plywood in the process of interior finishing work. This became possible due to the fact that the material is considered completely environmentally friendly and does not contain toxic components.

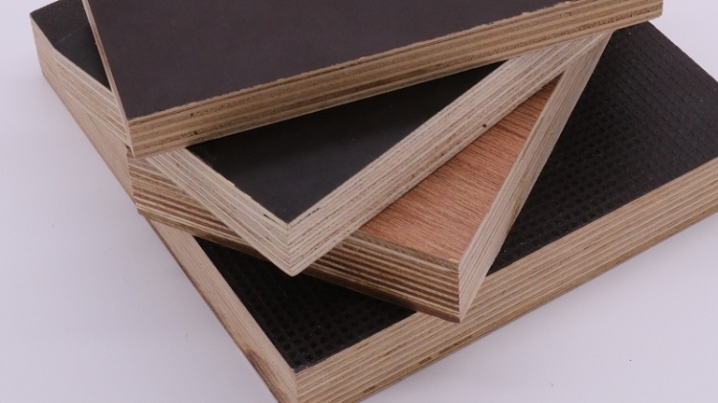

- FSF. A more advanced brand, the value of which is also at a high level. In the process of producing such plywood, a special glue made on the basis of phenolic resins is used. Birch wood is used as the main material. A distinctive feature of the material is its small thickness, so it can be used in external finishing works. But it is not worth using products indoors, since this brand contains toxic substances that can be released into the atmosphere during the use of the premises.

- FOF. Film faced plywood with unrivaled water resistance at the highest price point. This product can boast of its unique performance characteristics, due to which, even after years of use, the product does not lose its properties. In addition, the composition of the material does not include any substances harmful to humans, so this type of plywood can be used for interior decoration.

- FB (FBS). These are bakelized slabs, distinguished not only by their ability to withstand moisture, but also by resistance to mechanical stress. A high level of moisture resistance was achieved due to the use of phenol-formaldehyde resins in the production process.

In the construction industry, this brand is practically not used, however, it has proven itself very well in the aviation industry and in the process of building ships.

Dimensions (edit)

Plywood sizes vary from manufacturer to manufacturer. The average dimensions are 1.22x2.44 m, as well as 1.25x2.50 m. Of course, this is not all, but only popular dimensions. The choice of the most optimal one depends on the purpose for which the material will be used. As for the thickness of the slabs, it can be from 9 to 40 mm. It all depends on the number of layers of wood, of which there can be a minimum of 3 and a maximum of 21.

If the plywood is of the FC brand, then its length is 1.525 m. At the same time, the width reaches 1.20 or 1.55 m. The dimensions of FBS plywood can be measured in length, which ranges from 1.6 to 7.8 m, and the width does not exceed 1.60 m.

Applications

Waterproof plywood is considered to be quite versatile, so it can be used in almost any industry. The material received the greatest demand in construction. It is relevant when carrying out interior finishing work: covering walls, roofs and floors, as well as for creating decorative elements. In recent years, moisture-resistant plywood has been very relevant when creating billboards on the street, as well as in the production of containers. This material boasts durability, reliability and minimal weight, making it an excellent solution for shipbuilding and aircraft industries.

Thus, moisture resistant plywood is characterized by high quality, reliability and affordable cost. The versatility of this material is that it can be used in almost any industry. The most important thing is to choose the right type and brand, on which the degree of resistance to moisture depends, as well as the ability to cope with environmental influences. Waterproof plywood can be grooved, brown, white or black, shavings or birch.

You should pay close attention to every moment, because the effectiveness of the use of the material depends on it. The main difference between this material is that it does not lose its properties even when exposed to strong moisture.

In the next video, you will find a detailed overview of FSF moisture resistant birch plywood.

The comment was sent successfully.