Making metal doors with your own hands

The choice of metal doors on the market is large enough, and everyone can choose the best offer for themselves. But often the high cost of factory products frightens off, and its developers cannot predetermine all the needs of the buyer. In addition, custom-made designs with unique geometries or the use of atypical materials can result in significant cost and lead time increases. In case of self-production, you can be more confident than ever in the quality and perfection of the door you create.

With the right materials and tools and at least minimal skills in handling them, you can prepare a good metal door pretty quickly. The main thing is to strictly observe the sequence of technological operations and the requirements for each of them.

Peculiarities

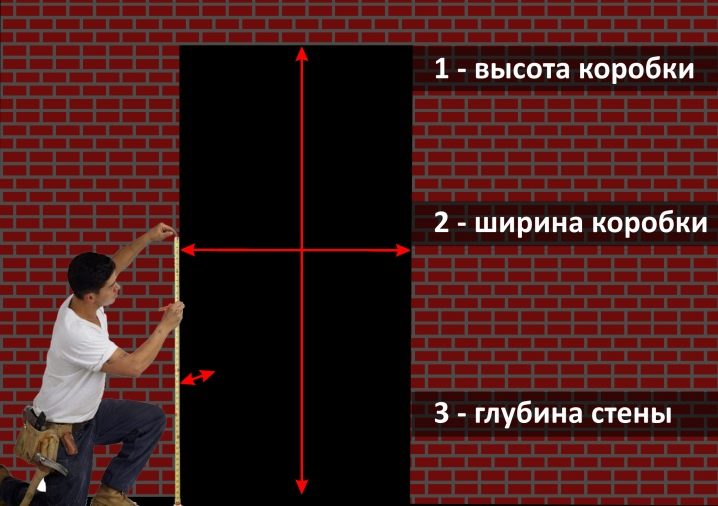

The production of the frame of metal doors begins only after measurements. On all sides, be sure to leave a gap of 2 cm so that the box easily and freely enters the opening. Gaps are also needed from the canvas to the box, and the sheet of metal should slightly go over the edges of the frame. The weld seam should not be longer than 4 cm, while for each meter there should be at least five seams. To make hinges, you need to take a metal rod with a diameter of 2 cm, which is welded to the box on one side, to the canvas on the other. A prerequisite for the success and long service of a homemade door is thorough anti-corrosion treatment.

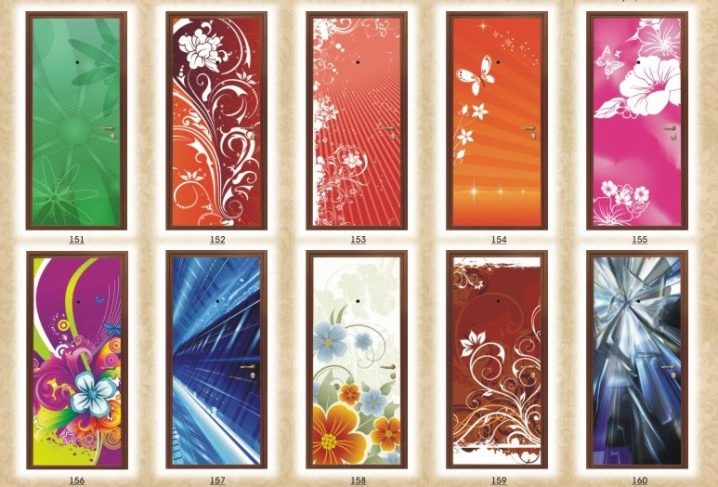

The choice of materials for cladding and its features vary very widely, in fact, you are limited only by your own stylistic preferences.

How to: step by step process

Assembling a metal door with your own hands will definitely require the use of:

- Steel sheet (thickness not less than 1.5 mm);

- Metal corner;

- Hinges (how many are needed determines the strength of an individual hinge and the mass of the block);

- Lock, handles and other accessories;

- External surface cladding material;

- Polyurethane foam;

- Anchor bolts and electric drill;

- Welding equipment;

- Welding table;

- Assembly goats;

- LBM with a disc for metal.

But this list is only approximate and preliminary, it can be modified and refined depending on which entrance door you need. High reliability is ensured only thick steel sheet or sandwich version, that is, a pair of sheets separated by an insulating material.

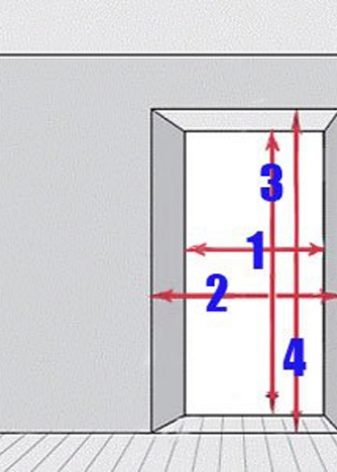

An iron door is sure to be made by exact dimensions. Standard openings reach 80-90 cm in width and 200 cm in height.

To completely eliminate errors in measurement, you need to reach the very base of the walls, knocking down layers of decorative coatings on a certain part of them. Or cut through the vertical casing with a hammer and chisel. You need to measure on each of the four sides, both inside and outside.

Leaving a gap of 2 cm you should not be afraid - it will help to correct the skew of the opening, and when the need for fitting is no longer necessary, it can be easily closed with polyurethane foam. A corner is cut strictly to the size of the box, it is placed on any rectangular plane, ideally on a welding table. If you use a trestle as a stand, do not forget to check their geometry. Only if the lengths of the diagonals coincide with each other, you can weld the corners.

In most cases, it is enough to create a structure from a 1.5 mm professional pipe or an equal angle 45x3 mm - a thicker structure will still not become truly armored, but it will turn out to be prohibitively heavy. With a low level of welding skill, it is worth buying a sheet of 0.2 cm, there will be less risk of burning it.

Further, in the profile with the help of a grinder, a cutout is made for the lock. Wooden slats of a certain length must be hammered into the frame, this will then simplify the sheathing of the structure. A hinge block from a metal profile is welded onto the hinges and the box, thanks to which the rest of the welding work will be noticeably easier. Pay attention to the accuracy of measuring the distances between the loops, they must be the same on the boxes and on the frames, otherwise the installation of the door at the entrance to the apartment will be too difficult.

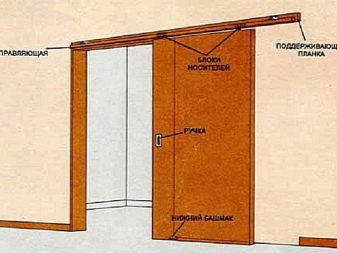

Making sliding doors is not much more difficult than ordinary ones. This solution will save a lot of precious space in small housing. The classic sliding system (compartment) can be suspended, cassette; some options are equipped with upper and lower guides. It is the last type that should be recommended to those who do the work on their own, because it is more reliable than others. But you will need to take care on the correct setting and fastening of parts.

The gaps should be as small as possible, the fit should be carried out as accurately as possible. A threshold or recess is made at the bottom so that the rail can be mounted.

It will take a lot of time to clean the guide, otherwise, under the influence of fine litter, it will quickly become clogged with dirt and fail.

Suspended systems can be attached to the top of the doorway or to the ceiling itself, depending on how high the door and the room are. The canvas in this version is 1-1.5 cm from the wall, and not a single piece of furniture will come out of this space. False panels, masking the upper rails, can be installed both on the very section along which the door moves, and on the entire interval from one wall to another. A more time-consuming, but also more interesting option from a design standpoint is the placement of a "border" around the perimeter of the room. Such a decision will have to be abandoned, if it is not possible to place the guide high enough.

A cassette door can be made if a special structure (niche) into which the canvas is to be removed was initially provided for when creating walls or partitions. You can use an additional drywall block, but it will absorb 10-12 cm of room space. When in the first place a tight fit of the door end when closing and enhanced sound insulation, and the room is large enough, this can be neglected. Unfortunately, even the simplest designs of sliding cassette doors that you create yourself will be very expensive to perform.

The cascade type differs from the traditional use of not one, but several canvases at once, for each of which a special rail is allocated. If you need to divide the room into two parts, the device should diverge like a partition. A group assembled next to one wall will be able to block the entrance to the room only by the width of a single canvas.

Assembling a product according to the "accordion" scheme is even more difficult. It is not recommended to do it yourself without professional installation skills. In addition, the "accordions" almost do not interfere with the propagation of sounds and the escape of heat.

To mount a radial sliding door, you will need to build a semicircular plasterboard wall; whether to install it in the doorway or use it as a full-fledged partition at full height is up to you and only you. If you wish, you can supplement such a design with a cassette, inside which the canvas will "hide". Most often it is formed from hollow walls inside. As in the case of the "accordion", if you do not have sufficient experience and skills, you should not take up the work.

The easiest way is to make a sliding hinged door.Calculate the fittings properly. It is better to lay an excess margin of safety than to face the sudden destruction of your product. The canvas will inevitably be larger than the doorway itself. The length of the upper guide is defined as twice the width of 1-2 canvases.

Double doors begin to be made, like ordinary ones - by measuring the existing opening. It should be 90-110 mm wider than the box.

If you need to narrow an unnecessarily large passage, apply:

- Lumber;

- Putty;

- Plaster.

By purchasing butterfly loops, you can avoid screwing them into the wall. When hanging a swing door, it is necessary to take into account the level of the floor, the horizontal and vertical axes are strictly observed. When gaps appear, they are sealed with polyurethane foam. Do not forget to carefully remove the excess, which necessarily falls on a free surface.

Masking of cracks is done using platbands; holes for the installation of handles and locks are made before the final hanging. When the installation is over, immediately check whether the sashes are straight, whether they open without hindrance or not. A safe lock with a cylinder or a lever device should be chosen at the entrance; an armored pad guarantees additional protection against drilling. Never place locks at the ends of doors, such an arrangement will make the home almost defenseless from any intruder.

To insulate a metal door, it is advisable to use mineral wool, which freely passes water vapor and does not accumulate moisture.

Installation of a door with a window is almost the same as usual work. The required opening is easy to cut with a grinder. Stiffeners must be prepared, including diagonal ones.

This opening is filled with a decorative lattice, and when the canvas is painted, you can start working with glass.

Welding technology

It is not difficult to weld a metal door yourself, but this must be done in small parts. Do not make seams longer than 4 cm. From the beginning of one seam to the beginning of the other, there should be exactly 20 cm. Work proceeds from the center to the edge using the reverse step method and from different sides. Cooking the door at home, take your time, Take breaks from time to time to cool down the product.

Then the workpiece must be lifted above the welding table, pieces of pipes and profiles are placed under the box. The hinges are made of steel rods with a diameter of 2 cm. To make them work better after being attached to the box, a ball from the bearing is placed inside any hinge. Watch carefully so that the axes of the upper and lower loops coincide. The top of the hinge is attached to the sheet, and its lower fragment must be welded onto the box.

The potholders must be cut off immediately after the hinges are welded. Entrance doors are polished and finished to perfection. You can insert the lock without any problems: a fragment is cut from the corner of the frame in such a way that it turns out to enter the lock without problems, but there is no gap left. After installing the locks, holes are marked for fasteners, keys, handles. These markings will help you drill suitable holes.

How to finish?

The door decoration is able to emphasize the asceticism and severity of forms or to bring a feeling of lightness and grace into the space. In both cases, solid wood and veneer can be used. Since self-assembly of doors is designed to save money, then the coating is chosen cheaper, warm MDF upholstery is often used, which is in no way inferior to more expensive products from elite varieties of wood.

An alternative to it can be considered:

- Leatherette;

- Plastic panels;

- Vinyl leather.

Please note that even if a material is selected for finishing the inside of the front door, it must be very resistant to mechanical and temperature influences.

Decor options

Non-standard metal doors must be finished in an original way.

Most often they are:

- Sheathed with wooden planks;

- Upholstered with soft materials;

- Pasted over with a film that reproduces the appearance of a natural tree;

- They are simply painted in the color they like.

Welded forged parts can look very stylish and attractive. They are able to radically change the appearance of the entire structure. In any case, regardless of the decoration method, you will have to start decorating with a primer and painting.

To decorate a metal door, a lining or other wooden plate, screwed onto self-tapping screws, can be used. In another version, the canvas is covered with leatherette, which hides a layer of insulation material.

Successful examples and options

The use of steel platbands painted to match the color of the main structure looks good. Having applied OSB, you will need to putty the surface if you still want to stick the film. Grinding will not work, no matter how hard you try to achieve a positive result!

The easiest way is to putty the rough coating not on the door itself, but before attaching to it.

Decorative films that imitate a panel look beautiful. Never use painted MDF outside, it is too weak. The consumer characteristics of laminated panels, which can be with interesting prints or patterns, are much better. And if you have free money and want to get a durable cladding, buy oak or birch, beech, mahogany veneer.

For information on how you can make a metal door, see the next video.

The comment was sent successfully.