Hinges for aluminum doors: types and recommendations for selection

Hinges for iron doors have their own characteristics. This is due to the considerable weight of the covering structures. The durability of the doors depends on the type of hinges, their quality and endurance.

Requirements

Hinges for metal doors are large. Various materials are used for their manufacture.

- Steel. It is characterized by reliability and moderate cost. However, this material is prone to corrosion.

- Stainless steel. Stainless steel is characterized by high strength properties, corrosion resistance.

- Brass. Brass products have excellent electroplating properties. Due to processing by means of casting, it is possible to create various types of designs.

- Aluminum. Hinges made of such material are characterized by aesthetics and low cost. However, due to their low strength properties and rapid wear, such hinges are not used in heavy metal door structures.

Loop elements must have the following characteristics:

- long service life;

- high quality;

- versatility;

- reliability.

The types of hinges for aluminum doors, as well as their technical characteristics, are regulated by the GOST 5088-2005 standard. According to the established rules, the elements have a certain size, shape, purpose.

Varieties

Depending on the type of hinge design, several types of models are distinguished.

- Models with a ball inside. The ball located between the rods prevents rapid wear of the mechanism and ensures smooth movements.

- Bearing models. Ball bearing mechanism provides ease of movement, long service life. The presence of the bearing significantly slows down the wear of the hinges, prevents the occurrence of a squeaky sound, jamming, and subsidence of the structure.

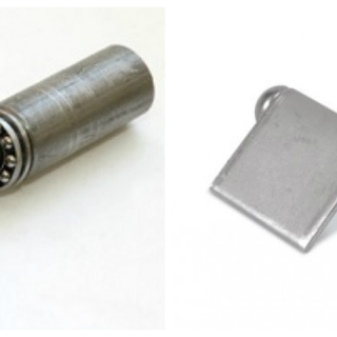

There are two types of ball bearing mechanisms:

- elements in the form of a cylinder with a ball;

- drop-shaped loops (shaped like a drop).

Both those and other roller elements have high strength characteristics. They are able to withstand the considerable weight of a metal door.

They also distinguish between types of hinges with a different installation method.

- Screw-in. The hinges consist of two cylinders one behind the other. Rods are attached to them. Their number can be different: from 2-4 rods. With their help, you can open the door in one direction only.

- Pendulum. With their help, you can open the door in both directions.

- Overhead. The elements are attached to the top of the box and door. They are rarely used in residential buildings.

- Spring loaded. These are hinge mechanisms in the form of two cylinders going one after the other. They have a spring inside the structure. The detail allows you to return the door to a closed state without anyone's help. Such 3-piece mechanisms are rarely used in metal doors, as they wear out rather quickly.

- Internal. The shape of the loops is in the form of a flat rectangle or a cylinder. The mechanism in the form of a rectangle is secured with pins. The hinge mechanism is unique in that it is completely invisible when the door is closed. Even with a strong desire, such loops cannot be cut from the outside, therefore they are most often used for increased security against penetration into the room. If the door is located on the street side, then there is no need to worry about the negative influence of the external environment - the hinges are reliably protected from corrosion and jamming.This can be manifested due to sudden temperature changes.

- Hinged. The structure is in the form of a rectangle with a cylinder with a hole on the edge. This mechanism is relatively inexpensive.

Mechanisms for fastening door structures differ according to the side of the fastening.

- Right-sided. With this arrangement, the door structure will move counterclockwise.

- Left-handed. In this case, the door structure will move clockwise.

- Mixed. One-piece mechanisms are suitable for any direction of door opening.

Selection Tips

Correctly selected door hinges will contribute to a long service life of the entire door structure, as well as provide the best functionality of the mechanism.

Before purchasing a door, it is important to think over its weight in advance, the opening option and what the load will be. It is also necessary to calculate the possibility of wall shrinkage, the influence of weather conditions, ensuring the safety of the room. With this in mind, it will be better to choose the type of hinges for attaching to the box. Ideally, the door mechanism will consist of elements matching in color and design.

If there is already a door, then it remains to choose the hinge elements. Here you will have to select the most suitable canopy option, taking into account the necessary requirements.

For example, if the door has a lot of weight, then it is better to choose cylindrical hinge elements with the largest number of pins. For this, ball bearing mechanisms with the best strength properties are suitable. If the door is lightweight, then options with a flat shape are suitable.

You can also solve problems with high weight when installing several attachments (more than two). This is especially true if the door will be used frequently, since the mechanism wears out quickly under increased loads.

In the event that the door faces the street, then for reliability it is more expedient to choose an internal type of canopy.

Such elements are characterized by versatility, aesthetics, and long service life. However, it should be borne in mind that this type of fastener has low strength properties: during operation, there may be cases of sagging. Due to the complexity of installation, the repair of such mechanisms is difficult.

It should also be remembered that internal canopies have a certain opening angle of the door - this can create considerable difficulties when bringing large objects into the room.

If the house is new and it is assumed that the walls will shrink, then perhaps the best option would be hinged elements with the ability to adjust.

When determining in which direction the door mechanism will open, the appropriate type of hinge should be selected.

An important role is played by the manufacturer's brand - the quality of products, strength properties, and wear resistance often depend on this.

Installation and adjustment

How door hinges are installed depends on their type.

In order to install the door on screw-in hinges, it is necessary to cut the upper part of the hinges into the door, and the lower part into the opening.

The hinge mechanism is easy to adjust both horizontally and vertically. The possibility of adjustment allows you to correct the processes of wall shrinkage. Any misalignment of the doorway can be smoothed out by twisting the hinges in the desired direction.

Depending on the type of hinge, the door height can be adjusted without dismantling or by shifting the elements. When carrying out work, one should take into account the reliability of fastening the awnings, the ratio of their positions. Only after making sure that everything is proportional, you can start welding.

In contrast to screw-in hinges, the internal awnings cannot be adjusted.

The hinges are attached to the door frame and frame using a hole in the cylinder. When removing the door, such hinges need to be dismantled.

In the case of a ball bearing mechanism, the elements in the form of a cylinder are welded to the plates - this provides the necessary clearance between the door structure and the fasteners.

In the case of a drop-shaped type of fastener, welding is not required, since the shape of the element technologically provides the necessary gap between the door structure and the fastener.

When installing a ball bearing mechanism with your own hands, some points should be taken into account.

- The door structure is fixed to the door frame in such a way that all its edges are in close contact with the surface. Gaps between doors should be the same on all sides. It is important to avoid distortions.

- Before work, the hinges are treated with grease, otherwise the ball may be welded to the hinge during welding.

- When installing the hinges, it is important to ensure a functional gap between the door and the fastener - only then start welding.

- After welding, the welding seams are cleaned. This is done for an aesthetic purpose.

- The final stage of work is surface treatment with a dye. This is done in order to protect the material from corrosion.

The installation process for the internal fastener is quite specific. It includes the following works:

- holes are cut for fasteners - they must be perfectly even;

- first, the hinges are welded to the inner surface of the lute, and then to the inner surface of the door structure.

The process is quite laborious and requires great precision and accuracy. Neglect of the nuances of the installation can lead to a rapid loss of functionality of the mechanism, breakdown. It will be difficult for an amateur to cope with such work, so it is better to entrust it to professionals.

To extend the service life of the mechanism, it is necessary to periodically lubricate it, adjust the position.

See the following video for the differences in door hinges.

The comment was sent successfully.