All about glass hinges

Special glass hinges allow you to mount doors and furnishings without drilling holes in them that could damage fragile materials. They have a special design that allows you to reliably fix even rather heavy and massive hinged elements. It is worth learning more about what types of glass hinges are in the assortment in order to make the right choice.

Peculiarities

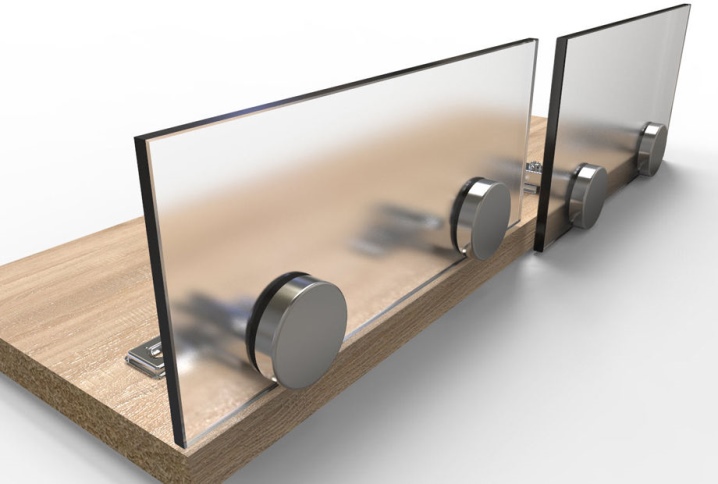

The main features possessed by glass hinges are directly related to their purpose. Since through fastening is not the best option, other fixing methods are used here. Most often, this is installation in special clamps that can withstand significant loads during operation. This is especially important in frameless structures where there is no edging made of wood or metal.

When installing in humid rooms, attention is paid to the corrosion resistance of materials, and sometimes to heat resistance, as is the case with the fastening of doors in saunas, walls in shower cabins.

One of the important requirements is the aesthetics of the hinges, because they remain visible on the surface of the transparent glass. With frameless fastening, these elements are selected so that they look attractive, have a symmetrical design without defects. One of the key parameters is the size of the loops. Too large elements will spoil the overall appearance of the door or other suspended structure.

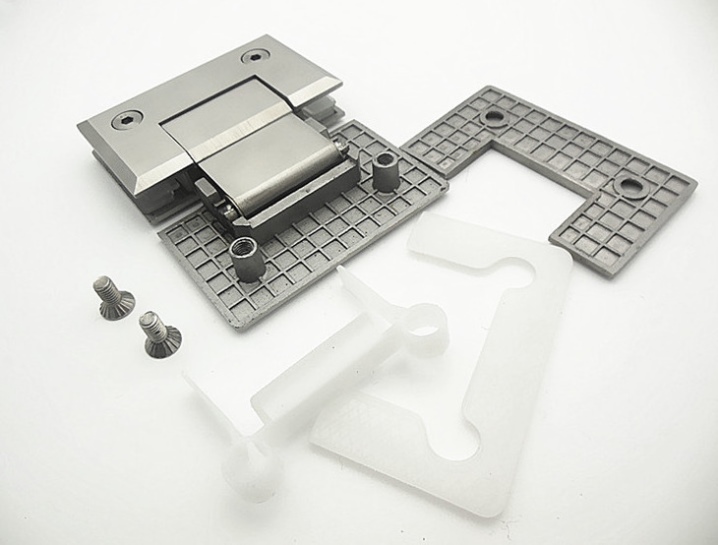

The presence of protective elements is another important distinguishing feature of specialized fasteners. Glass hinges are equipped with special gaskets made of flexible and resilient polymers. This avoids damage to the glass sash.

Species overview

Hinges for glass doors, sashes, furniture are divided into groups according to the features of their design, installation method, location. The internal structure will be fastened differently than the entrance one. The axial one differs markedly in the way of opening from the swivel one. Additional fittings also matter: models with a door closer mean automatic closing of the sash. All these factors must be taken into account in the classification.

By installation type

All hinged structures for glass elements are divided into mounted without drilling - inset, as well as through, screwed into the sash. They have different operational and functional loads. In the furniture industry, hinge fasteners are most often used, similar to both front doors and swing cabinet doors. They have special gaskets and can withstand a weight of up to 20 kg.

There are the following types of loops.

- Overhead. Used for tightly pressing the glass to the end line of the cabinet. Versatile and widespread.

- Half waybills. Necessary if the vertical supporting part of the structure holds the hinges for 2 sashes from different sides at once. The optimal choice for multi-section structures.

- Mortise. Provide full immersion in the end cavity, if necessary. Convenient in dressing areas with hinged doors.

- Inset with through fastening. In this case, the glass is drilled through and clamped with screws.

- Corner. They are needed for fastening the doors not at a right angle in cabinets that are complex in their design.

- Adit. Essential for corner furniture with false side panels.The hinge has a maximum bend of the lever, which makes it easy to use with a significant thickness of the support.

In addition, there are awnings created specifically for heavy suspended glass structures. They provide opening in different planes, do not spoil the appearance of the product.

By appointment

Here the classification is extremely simple: loops can be furniture or interior. For example, large-format fittings designed for a weight of 20 kg or more are installed on a glass door in a store, shopping center, bathroom or sauna. Hinges for the glass front of furniture, cabinet doors or showcases will be more compact. They are designed for glass thickness up to 10 mm and a load of no more than 20 kg.

By construction type

The main division on this basis is made on open (installed in plain sight), and hidden loops. It is customary to consider separately awnings... They are used in sliding and sliding glass doors and where the opening range must be up to 180 degrees. Reinforced hinges withstand the load of 2 canvases at once. The main classification is as follows.

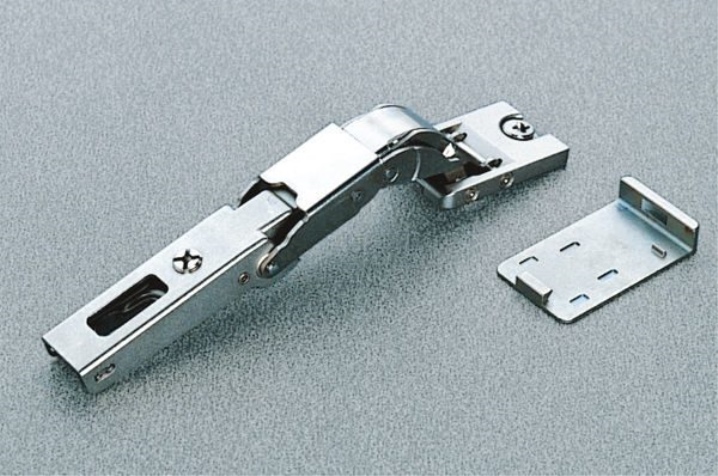

- Articulated. Traditional furniture options with a swivel mechanism. In the case of glass, hidden and semi-overlaid options are most often used.

- Reinforced. They use a four-hinge structure, which is fixed in 3 planes at once. Hinges allow you to expand the opening angle up to 165 degrees, they are overhead, semi-overlay and internal.

- Pendulum / carousel. Variants with a central pivot, on which the door leaf rotates around its axis. They can be equipped with limiters and other additional fittings, they are used when decorating entrance groups.

- Leading. Designed for sashes weighing no more than 20 kg. Needed for a tighter closure. Suitable for both wardrobes and doors.

- Hinged 180 degrees. Installed in bathrooms and showers or when fixing radial-type canvases.

- Universal. Can be mounted on either side of the glass structure.

These are the main types of glass hinges, distinguished by the type of their design.

By installation method

There are several basic methods of glass structures installation: with or without drilling of the sheet, with a clamp. For example, in furniture cabinets, cabinets and other furnishings, overhead hinge options are usually used.

If the structure provides for a frame made of wood or metal, installation can be done in the traditional way, with drilling.

Drilling connection

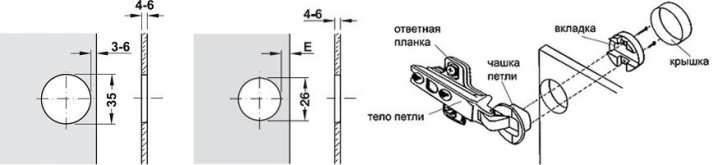

In the through installation of fittings, front cups and counter plates are used - decorative elements that cover the hole in which the fasteners are installed. The through connection is also used in all-glass doors. The mating part of the hinge is fixed at the required height in the sidewall of the furniture facade.

Only glass with a thickness of no more than 8 mm is suitable for drilling. More massive flaps simply will not hold in the base body.

For cabinets in an aluminum frame, special hinges have been created, designed to be fixed in the sidewalls of this metal. Their installation requires minimal effort, does not spoil the appearance of the glazing.

Clamping structures

Such glass hinges are equipped with grooves, inside of which fragile material is embedded. The pivoting element of the fittings is made of a U-shaped metal profile. The standard thickness of the opening is 8-10 mm, and spacers are also placed inside to compensate for compression and regulate the density of fixation. Most often, these liners have a vinyl or rubber structure, as well as an adhesive part that allows them to be tightly attached to the glass.

Adhesive bonding

Such hinges are attached to the supporting structure inside the body or on support pins in its upper and lower parts. Also, UV bonding technology can be used, with a composition that is polymerizable under the influence of rays. This option is good for all-glass structures. Canopies can be hinged or U-shaped.

Materials (edit)

Glass hinges are made of materials with high strength and corrosion resistance. Let's consider them.

- Stainless steel. Metal with a polished surface looks attractive and can withstand significant operational loads. The outer part is matte or glossy, and goes well with glass.

- Silumin or aluminum. Colored soft metals with a silvery-white surface are used in inexpensive lightweight structures. When oxidized, aluminum, like alloys based on it, changes color to a dull gray, and needs periodic cleaning.

- Brass. The non-ferrous alloy has a characteristic golden color, often enhanced by additional decorative spraying. The bearing capacity of such hinges is lower than that of steel hinges, but in terms of aesthetics they are superior to other options.

These are the main metals to consider when selecting glass hinges.

Ordinary steel is prone to corrosion, quickly loses its visual appeal, so it is rarely used without decorative chrome plating.

Top manufacturers

There are dozens of hinge options on the market suitable for use with glass structures, but not all brands are trustworthy. The best quality fittings of this type are made in the EU countries: Germany, Czech Republic, Italy.

Among them, one can single out a company Dorma - a German company and a recognized market leader. Italian Metalglas is also among the leaders. Among the popular brands, such manufacturers from Germany as WSS, Paul + Sohn GmbH... Russian firms are represented by brands Atlantic, Kinglong, Orman.

Selection rules

When choosing hinges for glass, you need to be guided by the basic principles that are important in fixing fragile material.

- Estimated load. It is calculated based on the weight of the suspended structure and the number of holders. The thicker and more massive the sash is, the more reliable the hinges should be. The presence of a frame and hanging fittings must also be taken into account.

- Opening angle. It determines how far the sash can be opened. For entrance groups, this figure should be 90 degrees or more. For hinged furniture sashes, a standard right angle is usually sufficient.

- The presence of adjustment. If possible, during operation, the hinges can be tightened taking into account the deformation of other elements. This is convenient, but not necessary.

- Appearance. Hinges installed on glass should be in harmony with the structure as a whole, provide it with additional attractiveness.

These are the main guidelines to follow.

Besides, it is not customary to combine tinted and colored glasses with brass mountings. In the bathroom and in the kitchen, the hinges must be stainless.

How to install?

Self-assembly of hinges with drilling in glass is not recommended. This requires precise equipment and calculation, otherwise the material is easily damaged. Working with fasteners without drilling does not require such efforts. It is enough to mark on the frame the place where the hinge will be located, fix the fittings with screws in the desired position.

Then a sealant and glass are inserted inside the groove so that the inside of the canopy adjoins it. After that, it remains only to adjust the level of clamping force with special screws, as in a clamp. Sometimes glue is additionally used for a stronger fixation.

The installed glass part must be checked for compliance with the specified geometry. The sash should not be skewed, open or close with force. Locking fittings and handles are installed after hanging the main structural parts.

You will learn how to properly attach the hinges to the glass door in the next video.

The comment was sent successfully.