Door frame for interior doors

The door frame for interior doors is a link between the doorway and the door itself. It is needed as a supporting part of the structure, on which the entire power load is concentrated. It is fixed rigidly to the doorway, and door hinges, extensions, platband and related accessories are already mounted on it. It also fulfills an aesthetic role and can be either a separate element of the assembly or an extension of a homogeneous structure.

Door frame materials

The door frame, as a rule, matches the material of the selected door leaf. Between the rooms, you can put an iron door, for example, an armored one, and then the box will be steel. Plastic and aluminum doors are now being installed in public places, offices, shops, and the box in this case will be made of the same material. For swing, sliding and glass doors, the trap (frame) can be made of MDF or aluminum.

For the manufacture of the interior door frame, the following materials are used:

- Solid bar with the selected bosom, that is, the porch. The timber must be of good quality, dried, without cracks and knots, because the internal tension of the wood between the fibers over time and under the influence of external factors can lead to deformation of the canvas.

- Wooden array. Elite types of wood are oak, beech and ash. Doors made of mahogany are very beautiful: cherry, alder, walnut and eucalyptus. Of the cheaper species, spruce, linden, birch, maple are used, pine is most suitable.

This material requires final processing: grinding, putty, firing, painting, staining, varnishing or mastic at the request of the customer.

- Spliced timber along the entire length of the product using the "mini-thorn" technology or glued timber from small pieces of wood using the same technology. Retail sizes - 35x70x2100 mm. This material also needs finishing.

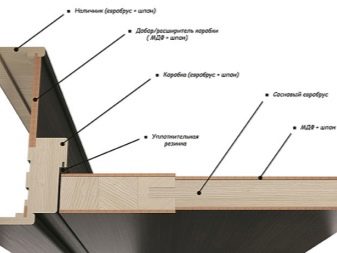

- Bars from MDF and HDF. Wood-based material impregnated with adhesives of medium and high density, pasted over with natural veneer. The thickness of the beams ranges from 30 to 60 mm, depending on the weight of the door leaf.

- Fiberboard strips Is a compressed laminated composite material with the required strength. Lined with artificial veneer.

Types of door frames

There are several types of door frames.

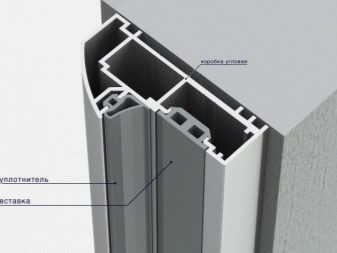

Corner

A versatile box that fits all types of walls. It is a construction of a decorative platband attached to the frame. The corner frame requires additional sealing of the gaps between the frame and the door leaf.

This will increase sound insulation and eliminate drafts.

End

It is used most often in an opening with thin partitions, for example, from plasterboard. This type of door frame is mounted in a metal frame to increase the reinforcement of the structure. Otherwise, the unreinforced structure will lead to loosening of the door mechanism as a whole.

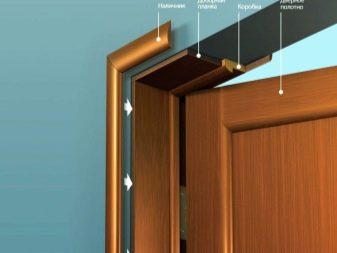

Encompassing

View of the box, consisting of a frame and an extension with a platband. The best option, which allows you not to worry about the preparation, revision and subsequent finishing of the doorway. As a rule, this type of box is already provided with sealing elements.

Telescopic

Represents a set of planks that are connected to each other in the manner of a designer or laminate locks. Simplifies the process of adjusting the door frame to the features of the opening.

It does not need gluing elements, as it fits together with grooves.

Profile configuration

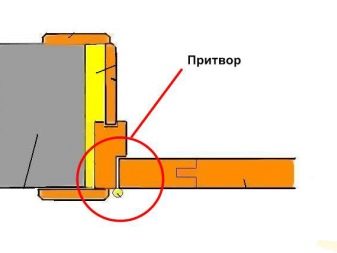

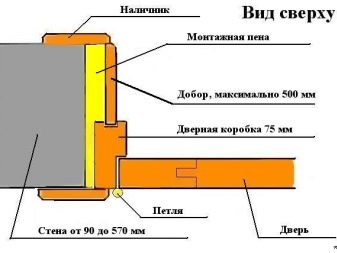

The door frame for interior doors is usually a rectangular bar with a selected quarter for the narthex.

The standard sizes are as follows:

- Thickness - 35 mm;

- Width - 60, 70, 80 and 100 mm;

- Length - 2100 mm;

- The width of the narthex is 30 mm and the depth is 10 mm.

The porch can be made in a semicircle or with ribs. For wide doorways in the timber on the back side, opposite the vestibule, a quarter is made for an additional 10/10 mm. In recent years, profiled telescopic boxes are increasingly being produced, into the side grooves of which the extensions and platbands that come with the kit are inserted. In the area of the vestibule, a groove is made for fastening the seal. If there is no such groove, then a self-adhesive seal is attached.

It enhances sound insulation and prevents the door from banging loudly when closed.

Box assembly methods

When buying a door block, the box can be attached to the door already assembled, but most often the door is completed with special bars made of the same material as the door itself. Sometimes the box has to be purchased separately. The assembled interior box has a U-shape, consisting of two vertical beams and an upper horizontal one. To the O-shaped form, another threshold is added in the form of a lower horizontal bar.

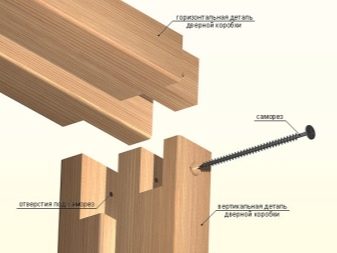

Large and thick boxes are assembled using a spike connection. To do this, grooves are cut out at the edges of one sheet, and grooves are made on the other sheet, corresponding to the dimensions of the grooves. The assembled spike joint is drilled through, and a key made of a denser wood is driven into the hole, or the joint is pulled together with self-tapping screws. Nails can also be used. When assembling, joiner's glue is used.

For the rest of the wooden boxes, it is enough to wash down the bars at 90 or 45 degrees and pull them together with self-tapping screws. All elements of the box with decorative features are cut strictly at 45 degrees. This job requires a miter saw or miter box with a fixed hacksaw. A hacksaw should have a blade with a fine tooth, for example, for metal. It is very difficult to prepare blanks reinforced with artificial veneer in another way, because it is simply impossible to putty or hide inaccuracies with any other method. These types include telescopic boxes.

Mounting

The door frame can be installed in different ways.

- Internal way. It is based on fixing the box in several places: in the hinges, under the lock plate and in the wall. In these places, the box is fastened with self-tapping screws, after which spacers are installed, and the resulting space is filled with mounting foam. This method provides a strong and durable fastening, however, it requires the utmost accuracy in the calculations and fitting the door, because after the foam hardens, it will no longer be possible to adjust the door.

- Bolt-on. Reliable and time-tested mounting option.

- Holes are drilled in the box.

- The box is applied to the opening, they indicate the places where it is necessary to make holes in the wall.

- The box is attached to the opening.

- The bolts are decorated with plugs.

- Suspension mounting. Hangers are plates attached to the box. After fixing them, the box is placed in the doorway, leveled and fixed with bolts in the hangers. This method is applicable only before the finishing of the room, since the suspensions on the wall must be hidden with plaster.

Casing box for a wooden house

Houses made of natural wood have the properties of "breathing" or "walking". This manifests itself when the wood dries out and the house itself subsides.So that the doorway does not lead along with the house, and the rigid door structure does not interfere with the "walk" of the wall, a casing (jig) is placed in the place of the opening. There are three main ways to install it.

They differ in the different location of the thorn:

- The thorn is a monolith. When the box canvases have a monolithic T-shape with a spike in the middle, and a groove for it is made in the wall opening.

- Into the deck. The box canvases have a monolithic U-shape with a groove in the middle, and the spike is made on the wall opening.

With a sliding block bar. This is the easiest way. It should be considered in more detail.

To work, you will need the following tools:

- fifty board;

- self-tapping screws.

- sealant;

- roulette;

- level;

- construction stapler;

- screwdriver;

- chainsaw;

- bar 50/50 mm;

- With a chainsaw, cut out the doorway of the required size. In the middle of its vertical sides, a groove is chosen for the bar. The same chainsaw cut off a bar less than the length of the groove by 50 mm. You can use not a solid block, but collect it from pieces. They hammer it into the groove so that it fits freely, but does not dangle. There is no need to fasten it, it is sliding.

- The board must be of the correct width. Cut it in length 50 mm less than the height of the doorway. In the upper part, cut a quarter 50 mm wide and 20 mm deep for the horizontal part. On the sides of the opening, strips of jute are shot with a stapler, leaving the bar free so that it does not screw on the screws. Planks are inserted into the opening and leveled. They are screwed with self-tapping screws 65-75 mm in length through to the bar, sinking in the canvas, while making sure not to stitch the bar through and through. The attachment points are putty.

- A horizontal board is cut to length. At the top, a quarter, apply a sealant and drive it into place. Fasten the box together with self-tapping screws from the back of the horizontal board. The distance left free above it is by no means foamed, but filled with tow.

Telescopic box advantages

In wooden houses, especially old buildings, one often has to deal with the problem of fitting the door frame to the deformed opening or the width of the walls. Before the advent of telescopic doorframes, these tasks were solved by using extensions and masking them with platbands. For the door to function properly, the doorway must represent a single plane on both sides. The telescopic device of the box solves the problem of fitting: the retractable fragments allow the box to be adjusted to any thickness of the opening.

Thanks to the elements moving in the grooves, it is possible to adjust the degree of adherence of the box to the wall.

Telescopic boxes are made of wood or MDF. Aluminum models are less common: they are more practical, do not dry out, and have a longer service life. Covered can be any color to match the door.

Installation of the telescopic box is simple and does not require professional skills. During installation, fasteners are not used, which then have to be decorated.

In case of repair, the box can be easily removed, and after completion of construction and finishing work, it can be put back in place. Telescopic boxes are suitable for absolutely any type of building. They can be successfully used both in new buildings and in the houses of the old fund.

Selection Tips

Before proceeding with the selection of a door frame for an interior door, all dimensions should be carefully verified, because the slightest error or inaccuracy of measurements can lead to the impossibility of installing the frame.

The door frame should be selected from the same material as the door.

For a massive door made of a wooden bar, an MDF box is not suitable, since under the weight of natural material the frame is simply deformed, and the door will cease to function normally. In hardware stores selling doors, you can contact a consultant for help with calculations.As a rule, manufacturing firms supply their products with special tables of standards and classification, according to which you can choose the most suitable option.

You can see what points you need to pay attention to when installing the door frame in this video.

The comment was sent successfully.