Installation of the door frame of the interior door

Sooner or later the moment comes when you decide to renovate your home with renovation. You will have to take care not only of furniture and wallpaper, but also of replacing interior doors. It is important to remember that the door is an important element of the interior, and it should look perfect, therefore, the installation process will have to be approached especially responsibly.

Peculiarities

A standard door unit consists of two elements:

- Boxes, consisting of an upper, mock and looped beam (boxes for blocks with a threshold, supplemented with one more lower beam);

- Doors.

The hinge beam carries the main load of the door.

The threshold is often not set, but sometimes necessary to avoid drafts.

Most often, the door leaf is hung with two hinges. The kit may include a door handle with a latch. If the platbands are not included in the factory set of the door block, they must be purchased separately.

In factory designs, the stationary platband is usually combined with the box. When assembling a box from separately purchased materials, it is better to purchase a telescopic casing, since it is very easy to install. When the door opening is wider than the door frame to be installed, the deficiency is made up for with extras. If you do not want to buy additional elements, the walls are trimmed with slopes. Too wide an opening can be reduced by installing a bar on the side of the hinge rack. In such cases, it is attached, like the feigned post, to the wall using anchors, and the hinge post is attached to the timber with self-tapping screws with a smaller diameter.

The door block consists of many parts, and for its assembly it is important to know all the parameters of the components. Their dimensions primarily depend on the height and width of the wall into which the door unit will be built. A box with a width of 108 mm will fit into a brick wall with a thickness of 70 mm. If the wall is 100 mm thick, the box size will be 120 mm. This is the size of typical finished blocks in our country. If you have a collection box, it is important to measure in advance.

Measurements are key during the installation process. It is important to carefully calculate the height of the uprights and the top bar. The dimensions of the finished box should be less than the dimensions of the doorway by 20-30 mm.

Thus, the gap between the block and the wall will be 10-15 mm. Sometimes the opening is much larger than required, in which case the excess gap is filled up with bricks or sewn up with drywall. If the gap is not too large, then the openings are filled with polyurethane foam from all sides, puttied and closed with platbands.

Doors can have different configurations:

- The door frame is fully assembled, with embedded hinges and a hinged door. This is a very convenient option. Everything is ready for installation, all that remains is to mount the block in the opening.

- Canvas and box. All parts are available ready for assembly. All elements are combined with each other, but not assembled. The consumer will have to put everything together and build it in on his own.

- Only the door leaf. You need to purchase all the necessary lumber separately. In this case, you have an advantage. You can adjust the box to fit the opening during assembly.

Door frames can be made from the following materials:

- From a bar. Such structures are very durable, but require special processing, since they are not attractive outwardly. They are treated with impregnations, stain, tinted varnish. The result is very strong and durable blocks.

- From fiberboard. Basically, it is compressed paper. This material is suitable for constructions with the lightest doors possible. Fiberboard door blocks are short-lived and quickly fail.

- Made of MDF. Door frames are as attractive as possible and strong enough. Their lifespan mainly depends on the topcoat. Usually it is veneer, laminate or PVC.

There are 2 types of door block shapes:

- Full box. Consists of two side profiles, lintel and threshold.

- In the form of letter P. This box has no threshold.

To replace the old door block with a new one, you need to follow these steps step by step:

- Dismantle the old door frame.

- Assemble the main supporting structure.

- Equip the door leaf and frame with the necessary fittings.

- Correctly install the box in the opening.

- Hang the door leaf.

- Install platbands.

When dismantling the old box, the platbands are preliminarily removed. The way they are removed will depend on the method by which they were attached. If they are planted on liquid nails or glue, then simply pry them off with a tool and pull them to the side. The same applies to telescopic platbands, they are easy to dismantle. If the platbands are nailed, you will have to use a nail grabber, and possibly an ax. When removing the false and looped beams, it will not be superfluous to saw them in the middle, this will facilitate their removal from the opening. Then you need to check the strength of the wall, and if necessary, then strengthen it.

For this, work is carried out on concreting. If the doorway itself is weakened, then set the steel corners "in the girth". You can reinforce the opening with a steel profile, or use corners and a profile at the same time for guaranteed strength.

Strengthening the old wall will significantly increase the service life of the door frame.

Assembly methods

Despite the fact that there are a lot of assembly methods, the most common among them are only 2, and they are easy to do with your own hands. The profiles are attached to each other at an angle of 45 and 90 degrees. The measurements are noticeably different.

45 degrees

All work is done on the floor. We lay out the profiles and carry out measurements and calculations.

We will have 3 details:

- 2 vertical profiles;

- looped and feigned racks;

- jumper.

To calculate the height of the vertical profiles, you need to add the height of the door, the thickness of the lintel, 2 gaps of 3 mm on each side and the thickness of the threshold, if provided. The length of the threshold and the lintel is folded in the same way - the width of the door, the thickness of the vertical profiles are measured and added, and 2 gaps of 3 mm are added. After the calculations, you need to make a markup and cut the timber.

Next, you need to mark the part of the vestibule profile that will be deleted. The marked part needs to be cut down, further sawing should be done to the depth of the ledge. We put the sawn bars around the door, marking the gaps by inserting pieces of cardboard. We mark the attachment points for future hinges, retreating from the bottom and top of 20 cm. We apply the hinges to the marks and bait on the screws to the corresponding bar, marking the place for sampling the material and the points of subsequent screwing. Using the mark made, select the material with a chisel to a depth corresponding to the thickness of the hinge flap. We screw the loops into the resulting grooves. We apply the upper and second vertical profiles, keeping the gaps, and check the perpendicularity of the elements in relation to each other. Then we connect with screws. They must be screwed in at an angle of 45 degrees to the surface and perpendicular to the cut of the joint. The screw holes must be drilled in advance.

90 degrees

In this version of the assembly, we will attach the upper beam over the side ones. That is, it must be placed on top. The length of the side profiles is calculated as follows: we measure the height of the door and add 2 gaps of 3 mm each if the threshold is set.If the threshold will not be installed, add 1 cm for the bottom gap so that the door does not touch the floor and does not scratch the coating. The entire assembly is carried out in the same way as the previous one, except that the screws must be screwed into the panel perpendicular to the surface.

We examined how the door frame will be assembled, but before installing a new one, it is necessary to dismantle the old block. We first remove the platbands. When removing the false and looped beams, it will not be superfluous to saw them in the middle of the height, this will facilitate their removal from the opening. Then you need to check the strength of the wall and, if necessary, strengthen it.

For this, concreting work is also carried out. If the doorway itself is weakened, then set the steel corners "in the girth".

The opening can be reinforced with a steel profile, or you can use corners and a profile at the same time for greater strength.

Installing a door block of an interior door is not an easy task, but with a competent approach and a detailed study of the nuances and features, almost everyone can do it. When installing a door into a wall with a standard thickness of 70 mm, using an add-on element, a mounting block is installed between the wall and the frame to reduce the door opening. The platband installed then will hide the additional element. This method is suitable when the doorway is even in height, but slightly larger than the required width.

On polyurethane foam

A door block with a fixed door and inserted spacers that maintain a gap between the door and the frame is placed in the prepared opening. The structure is carefully checked using a plumb line and level for vertical positioning and fixed with wedges in the wall opening. It is necessary to align very carefully in order to avoid further skewing of the door in the frame. Then the gap is carefully filled with polyurethane foam.

Apply the foam slowly, in small portions.

First, a thin layer, then an additional one, until the opening is filled. The main thing is not to overdo it. The box will stick exclusively to the foam. After it dries, the excess is cut off and the platbands are installed.

How to fix it?

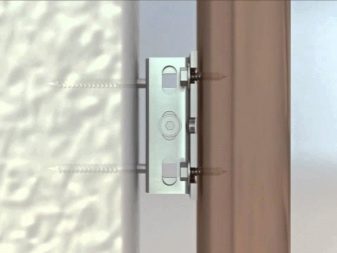

To fasten the door to metal hangers, you will need metal fasteners used when joining drywall structures. You will need at least 4 of them. The door with the installed fittings is hung on the frame, spacers or pieces of cardboard are installed in the technical gaps. Then hangers are screwed on the outside of the box. Then we insert the block into the opening and fix it with wedges. We align the structure correctly with a level. Next, we need to note where we will attach the suspensions. On the marked areas, select the material for the plates. Align the structure again and fix the plates to the wall. We plaster the grooves with screwed in suspensions, fill the gaps with polyurethane foam.

When fastening with the through method on anchors, holes for them are deliberately drilled in the marked places of the side profiles. First, we mark the places for the anchors, 2 on each side. With a 14 mm drill we make a hole for the plug. Next, we make a hole for the anchor using a 10 mm drill. We install the box in the opening, align and fix it with wedges. Then we drill the concrete with a special drill and install the anchors. The box, installed with anchors, is very strong. If you replace them with screws, the plugs will be one size smaller. At the end, platbands are installed. This method is ideal for installing particularly heavy doors.

Often, for greater reliability, the door frame is attached to anchors or self-tapping screws hidden under the hinge leaves.

Another hole must be drilled between the screws in the hinge flap. It is through it that the anchor will be attached. From the side of the porch, fixation is carried out under the lock plate. Thus, 3 attachment points are obtained. Spacers are installed under the door and the gaps between the box and the wall are foamed.When the foam dries, the excess is removed and the platbands are attached.

What if the door hits the box?

Sometimes self-installation of the block is not perfect, the door can cling to the profile and close with difficulty. It is important to understand why this is happening - the box or the door itself is swollen, and how these situations are eliminated.

If the box has moved, you need to check the hinges and make sure that the problem is not in them. Most likely, the polyurethane foam swelled up during temperature changes and the box was slightly deformed.

To fix this, you need to drill through the box with long screws and hide the holes with color-coded plugs. You can also use anchors.

If the door is made of wood, then you need to remove the lock and grind the end. To do this, you need to put sandpaper on a board or block to get a flat surface. When sanding, the door should be checked for touch. If the problem is resolved, we put the lock in place, and the sanded end is tinted and varnished.

We have considered the most common examples and options for installing interior door frames, as well as mounting methods. This will help to competently carry out the preparation and installation of the door block with your own hands. With a well-done work, problems during the operation of the door will not arise.

You can learn more about how to properly install an interior door from this video.

The comment was sent successfully.