Metal doors with a thermal break: pros and cons

Entrance doors perform not only a protective, but also a heat-insulating function, therefore, special requirements are imposed on such products. Today there are several types of structures that can protect the house from the penetration of cold. One of the best options are metal doors with a thermal break.

What it is?

Metal doors transmit heat very well, which does not allow maintaining the optimal temperature inside the room. Today, this problem is solved with the help of various insulation materials, which are placed under the sheets of the frame.

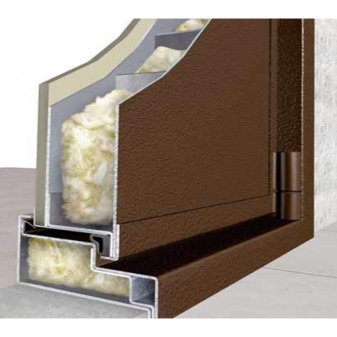

Thermal break doors - one of the varieties insulated structures. A feature of these products is the use of several layers of insulation, between which a thermal insulating gasket is placed. This layer can be a variety of materials with minimal thermal conductivity characteristics.

A door with a thermal break consists of several main components:

- inner and outer steel sheets (they are attached directly to the metal frame);

- cork fiber (this substance acts as an additional insulation);

- insulation (here they use two sheets, between which foiloizol or other similar materials are placed).

Iron doors of this type are often installed directly on the street. Their use indoors does not have any aesthetic and rational efficiency.

To improve the quality, thick steel sheets are used as the base material, which can withstand heavy loads.

Advantages

Thermal break doors are gaining immense popularity. They are perfect for various climatic zones where the temperature drops below 0. This is due to several advantages of such doors. These include:

- High performance of thermal insulation. With the help of such products, you can create comfortable living conditions inside a private house or city apartment.

- Qualitative technical properties. Doors are not only strong and durable, but also resistant to fire (they can withstand burning for a certain time).

- Wear resistance. The use of a thermal break excludes the formation of condensation on the surface of the web. This prevents the formation of ice, and also excludes the spread of corrosion on the metal surface.

- Soundproofing. The canvases are distinguished by good sound insulation characteristics. Such products will be the optimal solution for apartments near which noise is constantly present.

- Ease of use. The use of high-quality fittings eliminates the large weight of the canvas. Its movement is quite easy, which allows even a child or a fragile girl to cope with the doors.

- Durability. When manufacturing doors, the surface of metal components is coated with special protective agents (zinc-based polymer primer, anti-corrosion mixtures, etc.). They prevent corrosion and extend the life of all elements. To increase the resistance of the metal to mechanical damage, it is also amenable to laser processing.

disadvantages

Thermal doors are versatile designs that are perfect for installation as entrance elements. But such products still have several significant disadvantages:

- Considerable weight. Many doorways cannot withstand such designs. The solution to this problem is additional wall reinforcement with metal inserts.

- Incorrect installation. If the door is installed with a bias, then this will nullify almost all of its advantages. This design can allow air to pass through, resulting in heat leakage or condensation. Therefore, all installation work should be entrusted only to experienced and proven specialists.

- Simple design. Doors of this type consist of straight sheets that are attached to the frame. Today, almost no manufacturer supplements them with decorative elements. This makes the doors look monotonous and boring. But still, there are modifications that are equipped with small decorative overlays in the form of forged products, etc.

- Optimal microclimate characteristics. It should be noted that thermal doors are protected against ice formation if the amount of condensation is minimal. If there is high humidity in the room (especially from the street side), then the liquid itself will settle on the metal. With the onset of severe frosts, the outer side of the structure will begin to freeze over. Technically, this will not affect the interior in any way, but over time it can disable external insulation and lead to the formation of drafts.

Considering all the disadvantages of such products, the choice of a door with a thermal break should be approached very responsibly. Be sure to take into account customer reviews of various manufacturers. Some models may have a dramatically high price (most often this is a three-circuit model), but the technical properties will be almost the same as those of cheaper products.

This will allow you to choose not only a warm, but also a durable structure for a relatively small amount of money.

Insulation materials used

The quality of thermal doors depends on many factors, among which the type of internal filler is considered the main one. Today, in the production of three-circuit structures, several types of insulation are used:

- PVC. This material is one of the most affordable, but at the same time it is not able to withstand severe frosts. Therefore, PVC doors are suitable only for regions with a temperate climate.

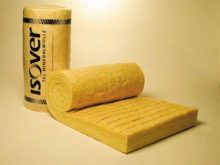

- Mineral wool and foam. Often these substances are combined together, which allows you to keep warm in the house in temperatures down to -25 degrees.

- Fiberglass. This material retains heat very well. But if the doors are operated at high temperatures, then this can provoke the release of harmful substances from the fiberglass.

- Wood. One of the highest quality heat insulators. This material perfectly retains heat without emitting any harmful components into the external environment. The only drawback of wood is its high cost.

Qualitative characteristics

Thermal doors are not only heat preservation products. Today, many manufacturers pay attention to other structural parameters of metal sheets. Such products have several strong technical properties. These include:

- Reinforced frame. Almost all doors are made of solid steel sheets, at least 2 mm thick. The frame itself is welded from a special profile that can withstand significant loads. This, in turn, leads to an increase in the weight of the web.

- High quality fittings. Here, locks and hinges are installed that are able to withstand significant blows, and can also withstand burglary for a certain time.

- The quality of the metal. All structural elements are made of improved types of steel, therefore, doors with thermal breaks are of much higher quality than conventional metal products.

- Fire resistance and tightness. It should be understood that all these parameters are not always present in thermal doors. Some of these features may exist, while others are not always relevant.

If certain characteristics are important to you, then such a door can be made to order from a trusted manufacturer.

For information on the differences between metal doors with a thermal break from other models, see the next video.

The comment was sent successfully.