Features of repair of door closers

Of course, polite people have always tried to close the doors by hand. But this affects their mechanism badly. Therefore, special closers have become widespread - but these parts also have to be repaired periodically.

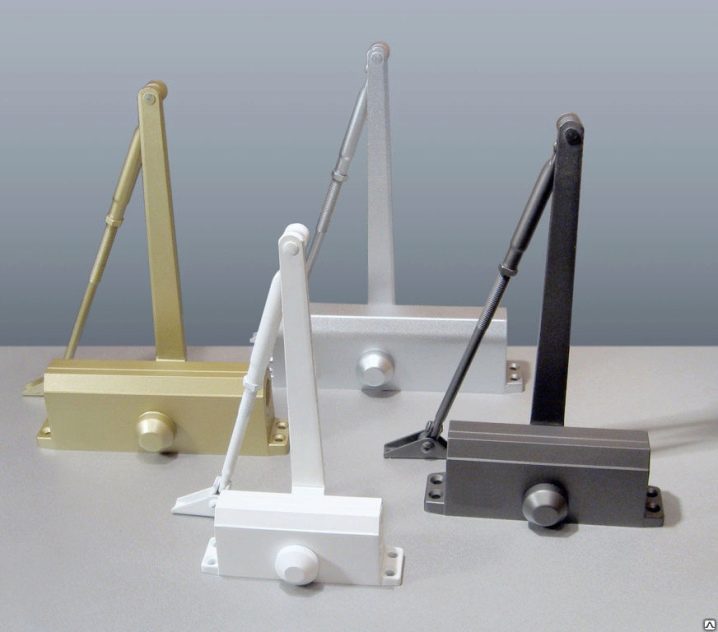

Types of closers

Already when buying door accessories, it is important to select them very carefully - then repairs will need to be done less often. It is worth paying attention to the design: the more complex it is, the more difficult it will be to fix the product with your own hands. A good door closer is one whose power is fully consistent with the severity of the web. The classification is based on the moment of inertia. Those products that allow smooth adjustment of the force are marked in a special way: the class of the system is indicated by a hyphen.

But this is not the only point that needs to be taken into account. You also need to pay attention to the permissible climatic conditions. Take into account the minimum and maximum operating temperature, the level of the difference. As for the design of the working mechanism, there are three main varieties.

Spring loaded. Morally outdated, does not allow you to control the opening and closing of doors.

Eccentric. It uses a shaped cam that can set an arbitrary moment of inertia.

Gear. The most massive group that allows doors to close softly.

The transmission of force is most often carried out by a hinge (lever) mechanism. The torque will be transmitted by a folding arm. It is this design that is quite reliable, lasts a long time and greatly facilitates repair. If a device with a sliding channel is used, it will look aesthetically pleasing, but it will become more difficult to use the door. It is even more difficult to open the door when installing a door closer on the floor, in addition, this option is rather complicated.

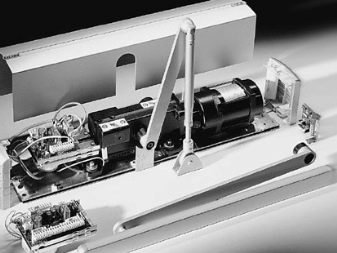

The linkage devices have a spring and an oil-filled hydraulic system inside. The purpose of this system is to amortize movement. When the door is opened, the spring must be compressed. In this case, the fluid moves under the pressure of the piston, and the spring is straightened. Since the tightness of the box can be broken, you must carefully monitor whether oil is leaking.

Symptoms and causes of failure

We must not forget that a door closer is a complex device. Therefore, its repair is not always possible. In some cases, it is possible to repair it, of course, but it will be very expensive. Common defects are:

leakage of working fluid;

mechanical destruction;

imbalance.

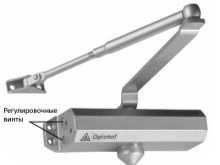

If the door closer opens tightly, you need to adjust it. For this purpose, a couple of screws are used, both must be adjusted strictly for yourself. Damage can be attributed to harmful effects of weather conditions. If the temperature is constantly changing, if it is snowing or raining, if the air contains a lot of dust, the structure can easily fail. When the closer does not work or works hard, the breakdown may be associated with improper use of the device.

Common mistakes are:

fixing the canvas in the open position;

opening the door to an unacceptable angle;

excessive force when opening or closing;

insufficient care of the closer.

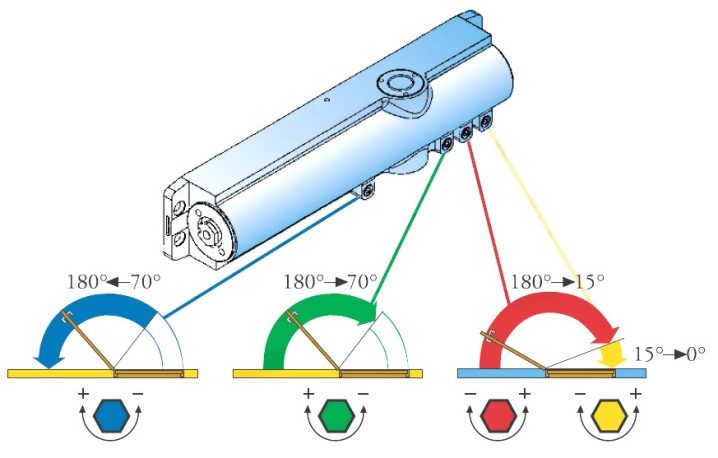

In winter, the speed of the door closer decreases, and in the heat it increases. This is due to a change in the viscosity of the working oil. Therefore, when changing the season, additional adjustment of one of the valves is required.If the door closer does not close the door completely, you must first of all be guided by the instructions in the instructions. Along with adjusting the speed, it is often necessary to adjust the intensity of the kick - to tighten the spring.

In some cases, the problem is associated with the insufficient strength of the apparatus itself. If this is the case, no amount of adjustment will help. Yes, twisting the spring will then give a positive result, but the shelf life of the product will be shortened. It would be much more correct to purchase a more powerful closer and replace the existing one. It is important to take into account that problems can also be associated with errors in the installation of closers, as well as doors in general.

Required tools

For the simplest problems that you can fix yourself, you need:

flat screwdriver;

curly screwdriver;

replaceable parts;

welding equipment.

DIY repair

Most often, liquid flows out of door closers in winter and autumn. This is due to the wear of the oil seals or the appearance of mechanical defects. If only a part of the workforce is gone, it is quite easy to fix the device. It remains to find an extra hole and close it. But if there is no liquid left inside at all, you can forget about the smooth opening of the door.

Even if the product looks the same as before, it will not be possible to repair it. Almost always, the body is completely changed. Things are much better if the lever is mechanically damaged. Bar breakage is most likely. This part of the mechanism is outside and is fully accessible to all destructive influences.

It doesn't matter what exactly happened - whether the knee was deformed, whether it was bent, or the structure was completely destroyed. In all cases, special welding helps. But it is important to understand that in case of serious problems, it will turn out to be too laborious a way out. Replacing the barbell will be much more practical in many cases. These parts are produced in a wide range, so it is required to check whether the purchased spare part is compatible with the installed design.

If you decide to carry out a full repair yourself, you will have to dismantle the closer. Unscrew the fasteners carefully. After parsing, the mechanism is laid out on a flat, solid surface. This will help prevent the loss of component parts. The first step is always to inspect the surface of the case to help identify mechanical damage. The problem area is degreased, after which the damage is eliminated using cold welding or glue.

Then you need to refuel the mechanism. For this purpose, open the hole where the adjusting screw is tightened. It is completely unscrewed. Attention: if constructively such an action is not provided, it is better to refuse it. Next, the working fluid is collected into the syringe and injected through the hole.

It is not necessary to fill in the oil with syringes. Any device that helps to deliver a narrow stream under pressure is suitable. After that, you need to get rid of the air that will be present inside the cylinder. This is done by repeatedly simulating the opening and closing of the sash.

We must act carefully and carefully. Both excessive strength and weakness in such actions are unacceptable. It so happens that a lack of oil is detected. In this situation, the missing volume is added, the mechanism is pumped again. Only after making sure of its normal operation, you can return the screw to its place.

Checking work

It happens that the mechanism is operated without any particular complications. In this case, there is no need for serious repairs, especially replacement of parts and oil. But still, the changing characteristics of the closers should be monitored. During long-term operation, the device must be adjusted. First of all, you need to monitor the speed and uniformity of the door.

An equally important point is how tightly the door adjoins the opening when the closer completes the move.If breaks occur, the temperature difference is almost always the cause. Closing the doors too quickly or too slowly is corrected by turning the control valves. The movement of the web can be slowed down by moving the valve in the direction of travel. Acceleration, on the other hand, requires the valve to be turned counterclockwise.

To adjust the speed of the door to the opening, it is necessary to turn the second valve. Sometimes it is required to hold the web when closing. This is done by leaving the door open at right angles. Bringing it to this position, tighten the latch vigorously. But you cannot turn it more than 2 turns.

Precautionary measures

In order to repair the door closer less often, it is necessary to inspect it at least once every 6 months and eliminate the detected defects. With daily use, you cannot:

"Help" the closer to close the door;

interfere with the closure manually or with the help of extraneous devices;

hang and fix heavy objects on the canvas;

allow children to use the door as a swing;

violate the provisions of the company instructions.

When servicing, it is necessary to add or change oil only of the recommended samples. Each company that produces closers prefers one or another option. At the same time, serious studies are being carried out showing how the reagent will affect the corrosion and mechanical properties of the product. In some designs, water-glycol formulations are used, in others, machine oil. Replacing one mixture with another is unacceptable.

But if the exact analogue of the technical fluid is not on sale, you will have to fill the closer with synthetic motor oil for cars. This is almost a universal option, but it is still worth paying attention to its behavior at different temperatures. Due to the high cost of such oil, many recommend using a shock absorbing fluid. But even here you need to understand that it is used at your own peril and risk - no one, except the owner of the door, bears any responsibility for the consequences.

How to repair and adjust the door closer, see the video.

The comment was sent successfully.