All about brushing wood

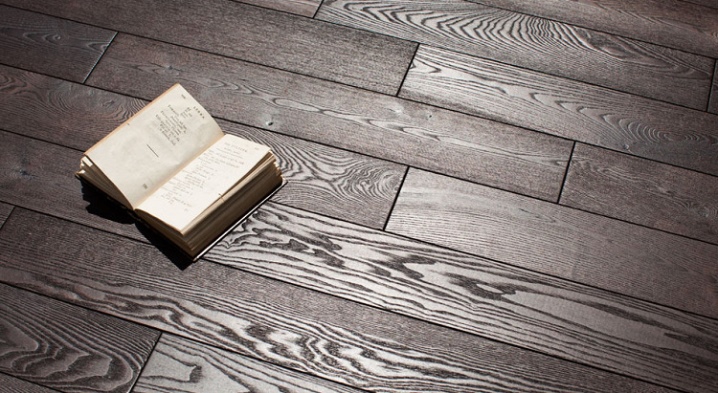

Wood brushing is a rather original technology that allows you to quickly give wood an aged look. This can be done even at home using the most common tool. A similar material is ideal for decorating rooms in vintage style, Provence and country.

What it is?

The use of wood in the design of the premises is intended to create a cozy warm atmosphere in the house, to emphasize both the originality of the home and its special atmosphere. All these tasks are perfectly handled by brushing. In addition, aged wood adds a special solidity to the interior and seems to hint at a rich history.

Brushing is a technology of mechanical processing of wooden blanks, during which the effect of antiquity is created on the surface. The technique involves the structuring of wood using the rough processing method.

It consists in removing all soft fibers from the surface layer of the material, due to which dense head rings create an interesting texture.

Let's highlight the main advantages of brushing.

- Improving the performance of wood. After processing, the material becomes more durable, less friable, resistant to moisture, mildew and mildew.

- Exceptional decorative performance based on visual contrast and texture after removing soft fibers. Such materials look harmoniously in any interior, make it stylish and expensive.

- Large selection of raw materials for subsequent aging.

- Tinting of treated wood can be done in different colors. It is allowed to use several shades at once. For example, the base is painted over with light tones, and the pores are made bright or dark.

The only drawback of brushing is the complexity of processing. This process takes a lot of time and effort for the master. In addition, when a brushed board is used as a flooring, dust will settle between the fibers, making it harder to clean.

The scope of application of brushed wood is wide, especially since the finished material can be given any look based on the general style and color scheme of the interior. It can be a combined shade range, patina, dustiness and moldy surface effect. Silver embossing, imitation of chips and cracks are very popular.

What is it for?

What is brushing for? It's simple. Structured wood is one of the most popular materials used for cladding any kind of interior. Thanks to such cladding, the interior acquires an original charm and uniqueness. However, for the embodiment of ideas of classic and vintage decor, as well as Provence, wood in its original form is not suitable.

The use of aged wood will be appropriate here, it can be used to make dressers, tables, stylish doors and window frames, as well as for facing fireplaces and making decor items. In the old days, to obtain the necessary texture, logs were buried in the ground for many years. During this time, under the influence of moisture and microorganisms, the soft fibers of the upper layers slightly rotted, after which the blanks were subjected to cleaning and grinding.

As a result, a relief texture of annual rings appeared on the surface. However, the original patterns on the surface of wood in natural conditions are formed very slowly, and the aging process of the material is delayed for many years. In addition, under the influence of precipitation, wind, ultraviolet radiation and temperature fluctuations, the material becomes less dense and durable, it is easily subject to decay, deformation and destruction.

That is why today they often resort to brushing, that is, artificial aging of wood. Moreover, interest in this technique is shown not only by lovers of vintage products, but also by supporters of eco-style in the interior.

How to choose a material?

It should be borne in mind that not every type of wood can be brushed - this is due to the difference in the structure of the fibers. Soft types of wood, as well as wood of medium hardness, are well exposed to aging, since the texture of annual rings is more pronounced in them. These include:

- oak;

- wenge;

- ash;

- nut;

- Pine;

- larch;

- Birch;

- cedar;

- acacia;

- Apple tree;

- aspen;

- alder;

- acacia.

After processing, such boards have a distinct relief, the pattern takes on an expressive look. The structure of furrows is visible on the surface, color contrasts appear. Moreover, the softer the rock, the more textured the surface will be. Most often, type-setting or unedged timber is subjected to processing. Certain types of wood are not suitable for artificial aging:

- teak;

- beech;

- maple;

- pear;

- Cherry;

- Linden.

The fibers of such trees are poorly expressed. The technology will also be ineffective for tropical trees - due to the peculiarities of the climate, they have no annual rings at all. Light aging can be performed on lining or plywood. Brushing does not change the performance of the material, it remains as dense. But at the same time, the surface becomes as expressive as possible.

Required tools

A site and minimum equipment should be prepared for structuring.

- A set of brushes with bristles of various thicknesses and degrees of hardness. They are needed for rough primary woodworking and removal of soft fibers.

- Emery. For rough sanding, coarse-grained sandpaper is used, for finishing fine polishing, fine-grained sandpaper is suitable.

- Decorative colourants. Most often, the workpieces are covered with stain, tinting impregnations, wax, and oils.

- Varnish. Suitable for fixing tinted layers.

With the help of such a set of working tools, it is possible to structure small areas of material, for example, in the manufacture of miniature decor items and small elements of furniture structures. When artificially aging wood in significant volumes (floorboards and wall panels), it is preferable to use professional grinders or specialized machines for brushing.

Alternatively, you can use a drill or grinder attachment. The use of a power tool will greatly facilitate the structuring process, save the time and effort of the master.

How to brush?

The technology of structuring and artificial aging of wood is widely used by designers when creating exclusive projects. This demand is explained quite simply: the material acquires a rather original and stylish look, but at the same time fully retains all its technical and operational properties. At the same time, you can do all the work with your own hands.

Metal brush

Most often, brushing is done manually. In this case, the wood is processed with a metal bristle brush - it removes the soft top layer, as a result, the texture acquires a relief. For structuring, brushes with iron or brass bristles are used. Disc-type brushes are used, it is desirable that in shape they resemble rollers with an extended end side.This structure will allow you to achieve uniform processing.

The thickness of the hairs is selected taking into account the characteristics of the tree species. It is important that the bristles are at least 7-10 times thinner than the softest veins. It is better to give preference to brushes with straight hairs, curled ones do not give the necessary cleanliness of the result. If the bristles are too stiff or wide, this will damage the natural texture of the material, as a result, the finished product will turn out to be unaesthetic. The brush should be guided along the grain line.

During work, movements should be extremely light, without strong pressure.

The metal brush performs rough structuring, after mechanical processing with brushes, the surface of the board is rough. To improve the result, they are passed through the material again, but this time with a nylon brush with abrasive powder. As a result, the surface becomes cleaner and smoother, hairiness is neutralized. During processing, from time to time it is necessary to tap the workpiece from the back side to remove all the dust. To obtain high quality, a finishing polish is added.

In this case, you will need a brush with a natural but hard bristle (for example, wool or sisal). Alternatively, you can use the rough side of the dishwashing sponge. At this stage, the wood is given a slight glossy shine and smoothness. If you direct the brush across the grain lines, you can achieve interesting scratch patterns.

However, such a technique should not be abused; in a large volume, such decor gives the finished tree an untidy look. It is better to resort to it on small inserts, this will give the board additional decor.

Drill and grinding discs

The high quality of wood structuring and time savings are provided by the use of an electric tool. When making a choice between a grinder and a drill, it is better to give preference to the second option, since the drill allows you to control the direction of material processing and the number of revolutions.

To perform deep brushing with power tools, specialized attachments are required, and they must match the same types of brushes as for manual brushing. In addition, it is important to take care of the strength of fixing the workpieces with clamps in advance.

Important: while working with a drill or CMM, a lot of wood dust is generated, so all work should be performed using PPE (glasses, respirator and gloves). All dust after processing is collected with a conventional vacuum cleaner.

Pre-firing method

To increase the efficiency of brushing, pre-firing of the material is often used. This facilitates the coarse removal of soft fibers and gives the products unusual shades. There are two types of wood firing in order to age the material.

- Chemical - a special solution is applied to the surface, including ammonia or alkali. Corrosive compounds change the shade of the top layers of deciduous wood.

- Thermal - the use of weak burning of all types of wood with fire and further grinding with a wire brush. The combined use of pre-firing and mechanical brushing produces unusual patterns and gives the material an exclusive look. To do this, they pass through the wood blank with a blowtorch or a gas torch. By adjusting the power of the fire and the number of passes, you can achieve a wide variety of colors: from pale yellow to charcoal black. After firing, manual or electromechanical brushing is carried out with a brush. As a result, dense annual rings remain dark after firing, and streaks of light shades form in place of the removed soft hairs.

You can also use the sand firing technique. To do this, it is heated to 200 degrees and the workpieces are covered until the wood darkens. After that, all soft fibers are removed with a regular brush. The final stage of any artificial aging is the toning of the processed material. Most often, the wood is covered with a water-based stain - such a surface is more embossed and textured. The composition is applied with a brush or sponge, and then the color is carefully rubbed in along the line of the fibers.

It is necessary to paint the brushed surface in such a way as to duplicate the cut-off pattern of irregularities. To do this, first, the surface is covered with a stain of dark or colored shades, especially carefully working out the depressions. Then, without waiting for the composition to set and harden, its residues are removed so that it does not have time to be absorbed into solid fibers. After that, the surface must be covered with a light color, paying special attention to the ridges.

When painting a large area, such as a floorboard or plywood, the dark color layer is dried. Then they are traversed over the surface with a petal disc with grain size parameters P400–800. At the end of the treatment, a light varnish is applied. At first glance, it may seem that the brushing technique is not particularly difficult. And in fact: if a small surface is structured, then problems, as a rule, do not arise. But if large surfaces are processed, many pitfalls are found.

So, when working with impressive volumes of wood, the standard performance of a drill or sander may not be enough. The tool is worn out, therefore it may fail. Reducing the number of revolutions can partially cope with this problem, but this reduces the overall productivity of the work. Holding a power tool at high speed requires severe physical effort. In addition, brushing is a rather long process associated with vigilant control over the operation of the machine, otherwise the relief may turn out to be heterogeneous.

Only a physically developed person who has the skills to work with the instrument can cope with such work.

Tip: for beginners, it is best to first get acquainted with the master classes - they contain step-by-step instructions for carrying out work on the artificial aging of a tree. You can find them on the Internet. Brushing pine or other resinous wood has its own characteristics. Due to the high friction, the brush heats up the wood to be treated. As a result, resins appear on the surface, and this creates a lot of difficulties in the course of further finishing.

Nevertheless, Despite the complexity of artificial aging of wood, today the technology remains one of the most common options for decorative surface finishing. It has become widespread in the manufacture of antique-style parquets, door leaves, steps, ceiling and wall panels, as well as window openings. This type of finish is popular for studios, shops, art galleries and cafeterias. Brushed material is often used in the decoration of residential premises. The structured wood gives any interior a great expressiveness and seems to hint at the "historicity" of the place.

In the next video, you will find yourself brushing a bar with your own hands.

The comment was sent successfully.