Everything you need to know about softwood

Thanks to its rich forest resources, Russia has long used wood. The most valuable material for shipbuilding, for the felling of a classic hut, furniture and household items often became coniferous wood. And today this raw material occupies one of the leading positions in the sawn timber market.

Features and properties

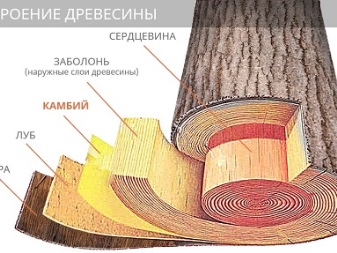

Features and quality characteristics of wood largely determine its structure.

Let's study the structure of the trunk, it consists of:

- nuclei - central part;

- sapwood - the peripheral part, lying under the layers of the outer and inner bark.

Considering the cross-section of a tree, you can see that in some species the color of its surface will be uniform, while in others a dark-colored core stands out. Depending on this, there is a division into:

- sound species such as pine, cedar, larch, yew, cypress, juniper;

- ripe - these include fir and spruce.

Evolutionarily, conifers appeared earlier, therefore, unlike deciduous ones, their anatomical structure looks simpler and more uniform and consists of cells of a certain type.

- Parenchyma - cells that store nutrients. They are located in the pith rays and line the resin passages. Their small amount (up to 5%) is due to the fact that a large proportion of nutrient reserves are in needles. The exception is larch parenchyma, their number is higher, about 10% of the tissue volume.

- Tracheids - the main element of the structure (more than 90% of the total volume). Arranged in radial rows, they look like elongated fibers with lignified walls. Living tracheids are contained only in the fresh annual layer and gradually die off. Early tracheids have wide cavities and conduct moisture. Late ones are narrow, with thick walls, and have a mechanical function.

Long fibers of softwood fabric are preferred over hardwood for the production of high quality paper and cardboard. A characteristic feature of the wood of many conifers is resin passages - horizontal and vertical thin channels filled with resin.

The largest number of them are pine and Siberian cedar. They ate fewer, but juniper and fir do not have them at all.

On average, coniferous sawn timber is considered lighter than hardwood. It is worth noting that during technological drying, coniferous material loses its weight per cubic meter by almost half. The specific gravity of a cube of freshly cut pine is 910 kg, and 1 m3 of dried pine is 470 kg.

Thus, due to the structure and physical characteristics of conifers, the following advantages can be distinguished:

- durability;

- low hygroscopicity;

- high resistance to decay and pest damage;

- strength;

- easy processing;

- Straight trunks contribute to fewer defects and improve the quality of the lumber.

What breeds are conifers?

All existing tree species can be divided into several groups according to a number of common wood characteristics.

Classification of wood species:

- conifers;

- hardwoods;

- wood of fruit trees;

- rare wood (grow in Africa, tropical forests of South and Central America, Asia, Caribbean islands).

Conifers are breeds of the order gymnosperms with modified leaves: needle-shaped or scaly. They are predominantly evergreens.In nature, such trees often grow not singly, but in an extensive group, in a forest.

The subclass of conifers has 5 families and a fairly voluminous list of plants:

- araucaria (agathis, araucaria, wollemia, cowrie);

- podocarp (legcarp or large-leaved podocarp);

- yew (berry yew);

- cypress (cypress, juniper, thuja);

- pine.

The domestic sawn timber market uses wood of 5 conifers, which are part of the "pine" family:

- pine trees;

- ate;

- fir;

- larch;

- Siberian cedar.

Pine

One of the most widespread species in Russia, pine forests occupy about 14% of the total forest mass. Pine wood has the following properties:

- low density 520 kg / m3

- high strength (when compressed along the fibers, the indicator is 440 g / cm2);

- high resin content;

- low electrical conductivity;

- ease of processing;

- monotonous structure;

- beautiful texture;

- low resistance to splitting.

Spruce

The breed has ripe, coreless wood, is distinguished by plasticity and a rather high level of strength, but is inferior to pine in this indicator - 80 N / mm2. It has an average resistance to decay, because its resin content is lower than that of pine. Due to the low density, it must be treated with formulations from decay. The spruce is characterized by a large number of knots. It occurs very often: more than 30% of taiga forests are spruce.

Larch

The only coniferous species that, like deciduous species, sheds its soft bright green needles and survives the winter with bare branches. With the arrival of autumn, its needles become golden and fall off. This cold-resistant breed can tolerate abnormally low temperatures and grows even beyond the Arctic Circle. Larch has the most durable wood among conifers, its limit is 105 N / mm2. Increased density and hardness, heavy specific gravity create difficulties in processing. Moody wood warps and cracks easily if dried improperly. Chipping is easy when planing. Other characteristics:

- low knotty;

- high resin content (in the Daurian variety of larch up to 22%);

- increased biostability;

- low thermal conductivity;

- resistance to moisture.

Cedar

Valuable Siberian cedar wood has excellent properties:

- density indicator - average, 320-550 kg / m3 (less than that of pine);

- the high content of phytoncides and resin ensures safety in terms of rotting and damage by pests;

- low thermal conductivity;

- splitting resistance;

- the wood is soft and lightweight, easy to process.

It is on the Siberian cedar that the familiar cedar cones and their delicious seeds grow. But the seeds of the Himalayan, Atlas, Lebanese cedar are inedible, covered with oily resin.

Fir

The breed has the following qualities:

- softness of wood;

- elasticity and light weight;

- lack of resin passages and pockets;

- high humidity;

- not very high ability to hold fasteners (25% lower than pine).

Application

Pine wood is the champion of the popularity of its application in construction, interior decoration, furniture production. It is used for the following purposes:

- erection of load-bearing structures of residential and utility buildings, floors, frames, rafters and piles, scaffolding;

- interior decoration of walls and floors (lining, board, plywood, chipboards);

- production of frame furniture;

- raw materials for the pulp and paper industry;

- resin is used in the chemical industry for the manufacture of turpentine, rosin;

- essential oil is used in perfumery and pharmaceuticals;

- modern shipbuilding - deck decks, inner planking, masts.

Spruce is widely used. They make from it:

- board, timber, plywood;

- skirting boards, platbands;

- furniture;

- stringed musical instruments, this is due to the high elasticity (it is from spruce that the tops of the famous Stradivari, Guarneri and Amati violins are created);

- cellulose.

Larch, enriched with resinous substances, is recommended for the production of piles and sleepers due to its resistance to moisture and strength, it is often used in shipbuilding and in hydroelectric power plants. A good option would be to choose larch for finishing the pool or bath. Larch parquet has served for many years (an example of this is the perfectly preserved floor covering of the Ostankino Palace of Count Sheremetyev). Earlier (until the 19th century) larch was highly valued and was not sold to private individuals. The main flow of raw materials was sent for shipbuilding, and if it was for construction, then only for selected buildings (Winter Palace, Moscow Kremlin, St. Basil's Cathedral).

Siberian cedar has a soft reddish wood with a very beautiful texture. In terms of resistance to decay, it surpasses spruce and fir. The production of joinery, furniture, lining and floorboards from this material is quite popular (especially for baths and saunas). A large amount of raw materials are used to make pencils. It is also used to make salting tubs, chests and storage chests. Phyto-barrels are in great demand - unique cedar mini-saunas. Fir wood is easy to process, weighs little, does not have a pronounced odor, therefore it is convenient to use it for the manufacture of various containers for food products: barrels, boxes, boxes. They also make window and door frames, baseboards from it. One of the main areas of application is the pulp and paper industry.

The soft and light cypress tree has long been used for the manufacture of church utensils, icon boards. Strong, rotting, almost not swelling when wet, juniper wood often becomes a raw material for various crafts and dishes. And earlier, piles were made from this breed (for example, in Venice), used in shipbuilding.

The yew tree has also gradually lost its distribution as a building material and is found only in the form of veneer, it is used in arts and crafts and to create musical instruments.

By the method of processing, all lumber is divided into:

- edged;

- unedged;

- one-sided edged.

Coniferous wood blanks are:

- sawn;

- glued;

- calibrated (dried and sawn to a given size GOST).

In appearance and size, they are divided into:

- board;

- bar;

- thin;

- thick.

Classification of sawn timber by grades - the assortment is assessed according to the approved GOSTs. GOST 24454-80 and GOST 8486-86 regulate the requirements for edged and unedged softwood lumber and distinguishes the following types:

- timber and bar;

- board;

- sleeper;

- lagging;

- croaker;

- rounded log;

- glued laminated timber;

- block house.

For long-term protection and decorative finishes, the wood can be coated with a tinting antiseptic. Since a feature of the structure of most conifers are channels filled with resin, it is necessary to demineralize the raw materials of such species with a special agent and preferably bleach. Deresined wood is easier and better painted and varnished. This can be done with technical acetone or a mixture of soda ash and water.

All softwood timber must be specially treated with fire retardants to reduce its inherent flammability.

The comment was sent successfully.