Calculation of timber: how many pieces are in a cube?

Knowing how much sawn or planed boards or beams are contained in one cubic meter is necessary not only for the customer, but also for the supplier. This allows you to reduce the cost of delivering timber to the construction site, as well as to quickly execute this order.

Cubic meter concept

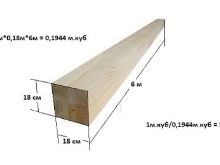

Since school, everyone has been explained what a cubic meter is. A cubic meter of space is a cube of 1 * 1 * 1 m, that is, the length, width and height coincide - one meter. In other words, it is a cube with an edge equal to one meter. A cube model is, in the simplest case, a frame pallet made of reinforcement and profiled steel, into which a cubic meter of wood can be placed, or a euro pallet (pallet) measuring one meter by one meter, into which, for example, the same 1 m3 of square beams or edged boards can be folded. When the planned repairs are interconnected - as well as the construction of a new facility - using solid wood (and not only), the customer will carefully review the preliminary calculation of the nearest building market, which indicates the cost of a running meter of the same edged board. In the case when the seller makes a start not from the molding, but from the cubic capacity of wood of a particular type and format of one real specimen, buyers specify how many specimens of a bar - or a board - will contain a "cube" of such a building material. The simplest method to clarify how many elements of a bar are in a cubic meter is tabular data. In their absence, knowing the dimensions of one specimen of the wood material of interest, the calculation formula will help.

According to GOST No. 8486-1986, wood materials are elements of a specific section and length. Without this data, it is impossible to determine how many boards - or beams - are included in a cubic meter. To find out the size of the section, step back from the end of the timber no more than 1 dm, and determine the section of the beam. It is calculated based on the product of these two numbers. The resulting value is multiplied by the length of the same beam.

Do not forget to convert all results to meters before calculating. Then the cubic meter is divided by the volume occupied by one bar.

Having calculated the number of elements included in one cubic meter, the builder also determines, based on the data on the density of a particular type of wood, how much this "cube" weighs. And also - how much the wall of a bar weigh, flooring from a board - and what is the load on the foundation.

The easiest way is to come to the representatives of the construction company and explain to them what you expect to see in the end. You will be offered ready-made projects - and you, in turn, will agree to them. If this option does not suit you, then all the calculations, including the organization of the construction site and the costs of it, you make yourself. Cost, weight per cubic meter, number of beams or planks per cubic meter is just one of dozens of construction stages. After going through the building markets, the customer will find out what is the cost of building materials - in particular, a board or timber - on average in the city and how much the estimate for the entire construction intersects with reality.

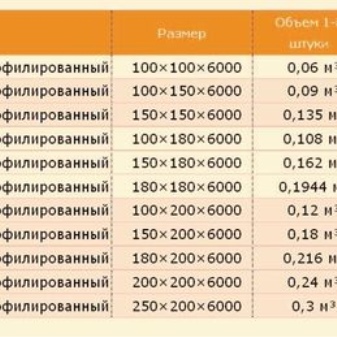

The overwhelming majority of construction firms determine the number of beams or boards of a specific size in cubic meters, which are then specified by the piece. Most loggers and construction markets rely on the most common timber - 6 m per unit of timber. In order not to saw the bar into smaller lengths, the handlers cut, for example, the bars into elements of 150 * 150 * 6000 mm.

This enables consumers to avoid unnecessary overpayments.

Calculation features

In general and in general, the algorithm for counting saw materials is the same and understandable to everyone. Clarifications relate only to a specific standard size of elements.

To measure the space occupied by a particular catalog item, its length is multiplied by its width and height. Then the "cube" is divided by the volumetric space occupied by this instance. To speed up the calculation, arm yourself with a calculator.

How many beams of different sizes are in one cube?

Having at hand the data from the price list for sawing materials, the consumer will calculate, without the participation of a consultant, how much the purchase and delivery of the selected products will cost for the construction site. Large quantities can be delivered free of charge.

Glued laminated timber is especially worth mentioning. Such specimens from two or more boards of the same width and length are glued together. The thickness of the board, multiplied by the number of its copies, from which the timber itself is glued, is equal to the height. The glue is absorbed into the wood and takes up so little space between the layers of the board that its insignificant thickness can be neglected. The number of copies of laminated veneer lumber is calculated in the same way as ordinary (sawn). By default, an instance of a six-meter segment of such a bar is taken. But at the request of the client, the recalculation is carried out according to the four-meter model - if such ready-made copies are already in the warehouse.

100x150

To determine how many beams are 100x150x6000 per cubic meter, multiply 6 by 0.15, and then by 0.1 m. The resulting volume reaches 0.09 m3. In this case, one "cube" is approximately 11 whole bars 1 * 1.5 * 60 dm. If you order 12 pieces of timber (one extra), then the performer (seller) will not cut off from the 12th 75 cm, but will provide you with it in its entirety. Cubic capacity 12 pcs. 1x1.5x60 dm will already take up 1.08 m3. Therefore, upon discovering that such an abnormal situation has arisen, it is advisable to “round up” up to a whole item, overpaying a little - and it will come in handy for you, and the seller will not look for someone to sell the remaining piece of wood to.

100x100

Let's replace in the previous example one of the values - 150 mm by 100 mm. And let's multiply the rest - unchanged - values. So, for 100x100x6000 we get 0.06 m3 per 1 piece. Approximately 1 m3 will be 16 bars 1x1x60 dm. Since the remaining piece-appendage may not be counted or you will have to cut the next whole, it is advisable to take a multiple of cubic meters. For example, 3 m3 of the same beams is measured by their number of 50 pieces, which eliminates the need to "spoil" the whole extra beams without urgent need.

By the way, for 2-meter boards, their number per cubic meter will stop at around 48, and for 4-meter boards, there will already be 24 such beams.

150x150

Now let's substitute both values - dimensions in the section - 1.5 dm each. The length remains the same - 6 m.We get 0.12 m3 per piece of timber 150 * 150 * 6000. Volume less than one meter - 0.96 m3 - contains 8 pcs. such lumber. In order not to cut the ninth from the same stack, it is permissible to take all 9 - their volume will be 1.08 m3.

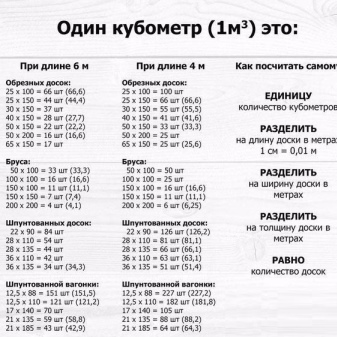

Edged board

Edged board - in the simplest case - is also released in six-meter copies. Some building markets, depending on its cross-sectional area, can cut 12-meter logging into three four-meter ones - each such board. A number of smaller building stores cut six-meter ones into two-meter and four-meter ones, or only 2-meter ones. It is easy to find out how many boards are 2 and 4 meters in each cubic meter by multiplying the obtained data for six meters by 1.5 or 3, respectively. It makes no sense to cut less - whether to divide the elements into smaller components is up to the customer himself. As initial data - the number of edged boards per "cube", the number of the same elements in the "cube" of wood (for boards of different sizes):

|

Dimensions, cm |

Number of copies per "cube" |

Space occupied by one board |

|

2,5x10x600 |

66 |

0,015 |

|

2,5х15х600 |

44 |

0,022 |

|

2,5х20х600 |

33 |

0,3 |

|

3x10x600 |

55 |

0,018 |

|

3x15x600 |

37 |

0,027 |

|

3x20x600 |

27 |

0,036 |

|

4x10x600 |

41 |

0,024 |

|

4x15x600 |

27 |

0,036 |

|

4x20x600 |

20 |

0,048 |

|

5x10x600 |

33 |

0,03 |

|

5x15x600 |

22 |

0,045 |

|

5x20x600 |

16 |

0,06 |

|

6x15x600 |

17 |

0,058 |

As a specific sample - the calculation of the number of copies of edged boards in a cubic meter of timber, the dimensions of the edges of which are 100x25x6000 mm. One will take 0.015 m3, and the number of whole specimens is 66 per 1 m3. If we take 67 from the same stack, then the total volume of such wood will be 1005 dm3 or 1.005 m3.

Grooved lumber

The tongue-and-groove board has a small peculiarity - it is recommended to drive the spikes into the grooves if the board did not have time to bend during transportation and is not packed. If each board has a plastic wrap, then in order to calculate the number of boards in a specific volume, the spikes can be neglected. But the tenon is not taken into account - only the length of the main part of the board is measured. The same applies to the lining. As an example, here are the five most common grooved edged timber options:

|

Dimensions (edit) |

The number of boards per "cube" |

Space occupied by one board (transport value) |

|

3.8x11x600 |

39 |

0,025 |

|

3.8x14.5x600 |

30 |

0,03 |

|

4x11x600 |

37 |

0,026 |

|

4x15x600 |

27 |

0,036 |

|

4.5x11x600 |

33 |

0,029 |

So, for a grooved sample 38x145x6000, the number of boards in a "cube" is 30, and the volume occupied by one packed board is 0.03 m3. There is no need to buy extra cubic meters in this example. Medium (smaller in cross-section) specimens already belong to the lining, even smaller ones - to decorative slats for all kinds of purposes. "Shelving" is the largest timber after profiled timber - there are several spikes and grooves on each specimen, not one at a time.

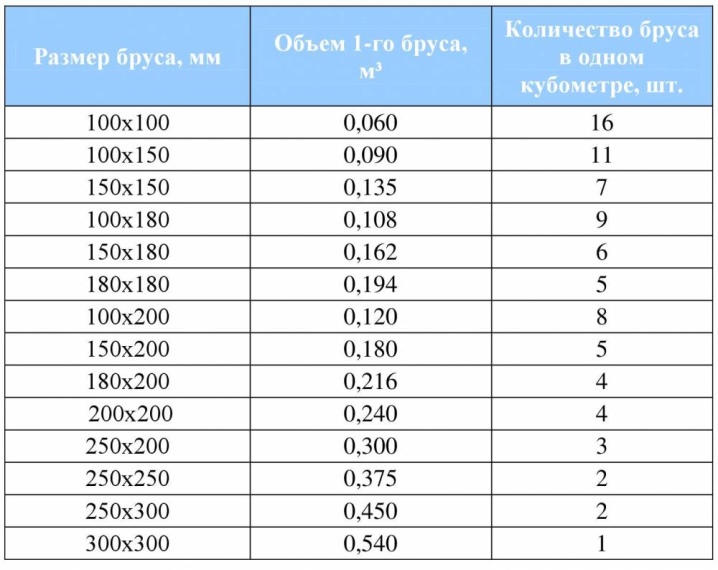

table

To facilitate calculations, use tabular data on the parameters of the timber. There are 15 most common dimensions of timber products available in the catalog of each building market:

|

Element dimensions, cm |

The number of pieces of timber in the "cube" |

How long will one copy take |

|

2,5х5х300 |

266 |

0,0037 |

|

3x4x300 |

277 |

0,0036 |

|

3x5x300 |

222 |

0,0045 |

|

4x4x300 |

208 |

0,0048 |

|

5x5x300 |

133 |

0,0075 |

|

5x7x300 |

95 |

0,01 |

|

5x5x600 |

66 |

0,015 |

|

10x10x600 |

16 |

0,06 |

|

10x15x600 |

11 |

0,09 |

|

10x20x600 |

8 |

0,12 |

|

15x10x600 |

11 |

0,09 |

|

15x15x600 |

7 |

0,135 |

|

15x20x600 |

5 |

0,18 |

|

15x30x600 |

3 |

0,27 |

|

20x20x600 |

4 |

0,24 |

Most construction stores and timber yards release beams of 3 and 6 meters. You can get a 2-meter one by sawing a 6-meter one into three parts.

The comment was sent successfully.