How to connect a bar?

During the construction of a wooden house, when redeveloping premises or performing other types of work, many beams and crowns have to be fastened together. It is worth remembering that each design has its own characteristics and structure. Therefore, you need to know which type of fastening should be used in specific circumstances.

Types of fasteners for timber

There are many mechanisms for how to hold the bars together. For this purpose, you can use various kinds of wooden cutouts that interact with each other. And you can also use construction accessories made of metal alloys. Such fasteners are created in different shapes and with a different number of holes, so it is possible to choose a universal option just for the desired case.

The basis of the lumber fasteners is made up of corners. This is the most versatile way to secure the bars. They can be mounted on nails, screws, screws. At the same time, they can be performed in various shapes and sizes.

In addition to corner fittings, there are other fittings. Among it you can find flat figures (steel plates), and iron brackets, which are driven into the ends of the beams, fastening the crowns in pairs.

Special attention should be paid to the mechanism on screw piles. Its use allows you to save on an expensive and strong foundation when installed on unstable ground without the risk of skewing the building.

Compound with the remainder

Such a connection is also called "in oblo". In this case, the nodal structure is a lock and has different types of assembly.

Unilateral

The most common and convenient method of fastening, equally well suited to both regular and profiled timber. On one side of the material, a saw is made to make a groove perpendicular to the axis of the timber. In thickness, it reaches half the thickness of the material. This option for laying beams consists in inserting a perpendicularly located building element into the groove.

A properly formed castle is characterized by strength and density. It fits from the underlying crowns, which are directed in one direction and combine well with them. Additional strength of the entire corner structure is provided by the use of fixing pins.

This method is ideal for creating a simple triple mount (tee).

Bilateral

When joining lumber on both sides, it is necessary to make a pair of grooves at the top and bottom. Wherein their depth should reach a quarter of the thickness, and the width is made equal to the bar.

Four-way

Four-way connection "in the field" is the most reliable variation of this method. but such a fastening requires great skill and professionalism from the carpenter when performing, because you need to correctly calculate the width and depth of the grooves. And also the material itself cannot be damaged. This method involves cutting grooves on each of the edges of the timber.

How to connect without a remainder?

Sometimes you need even and smooth corners without protruding beams. To do this, use the following fastening methods.

"Butt"

This mounting option is one of the simplest. In it, the bars are attached at an angle of 90 degrees using special fixing brackets or unified fasteners. Moreover, this method is suitable for both horizontal and vertical beams. The wood itself is not processed. In this way, various kinds of temporary structures, sheds, field storage facilities and much more are collected. At the same time, the finished structure can be easily disassembled and reassembled, because the lumber does not undergo irreversible structural changes.

The technology of joining timber "butt-end" has received an innovative modernization after the creation of high-tech woodworking equipment. Now, to strengthen the fastening, a hidden tenon groove and a key in the shape of a trapezoid are used. Such a lock received the name of a root thorn, its shape and dimensions are standardized and officially approved by GOST. This fastener is made on a modern milling machine.

The reliability of the product is given due to high-precision billet processing. The spike is firmly fixed inside the workpiece.

Such fastening can be strengthened with construction glue, and the corners of any building, assembled in this way, can boast of their strength and tightness. In this case, the front side does not need to be subjected to any processing. Due to this, the woody texture retains its homogeneity, which makes the facade of the building attractive.

With a key

This connection is one of the most reliable fastening methods.

A dowel is a small block that is usually cut from hardwood. It requires special grooves, which are erected in the central part of the end of the first beam and on the longitudinal edge of the second. Moreover, they are cut in such a way that, when applied, both elements fit perfectly together. The end groove is one third of the entire end surface. This means that the second fastener must be at the same distance from the edge. After creating the grooves in them, it is necessary to hammer the key with an interference fit. The advantage of such a connection is the complete elimination of the displacement of the bars relative to each other.

The position of the cut groove can be made perpendicular to the end face or at an angle to it. The latter mounting method reduces the likelihood of parts displacement even under heavy loads. A horizontal arrangement of the key is also possible.

This method is most often used when fastening outside corners, as well as when erecting internal walls. This is facilitated by complete freedom in choosing the distance from the edge of the timber for cutting a keyway.

Into the root thorn

The use of a root spike is successfully used in longitudinal splicing of bars. The advantage of this method is that no additional elements are needed for such a connection. Instead, a ledge cut out at the end of the beam itself is used. It is formed in its middle and makes up one third of the end area.

Simultaneously with the spike, a groove is cut out at the end of the other bar, which coincides in size with the first. The fastening itself occurs by reinforced driving of the spike into the groove from the side. Reciprocal forms do not matter: they can be ordinary rectangular, prismatic, dovetail combinations.

To increase strength and thermal insulation, you can use not only the spike and groove located perpendicular to the ends, but also at half a right angle. This option is much more difficult to implement, but it will give strength to the connection and reduce its thermal conductivity. In some cases, one root spine is bifurcated or even wasted, which also increases the heat retention rate.

This option requires proper skill, because poorly made fasteners, due to their subtlety, can break and destroy the connection.

Wherein there is a connection through a non-root spike. Unlike the first, it is close to the inner edge of the timber and is used to tighten the corners.

"Dovetail"

This mounting method is considered one of the most heat-insulating for the home. GOST 30974 - 2002 serves as the normative regulation for its implementation. The dovetail joint is reliable and durable. This corner does not need additional fasteners.

The structure of this design is most like a root spine. For its implementation, a spike and a groove must be cut out at the end of the timber. For the connection to be successful, they must be identical and form an airtight corner with each other. The main difference between the groove in this design is its trapezoidal shape.

The dovetail mount is used for joining corners as well as T-walls and regular lengths. This type of connection eliminates the need for additional gaps on the interior walls, which, in turn, makes it possible to use a beam of a smaller section in construction and increase the free space in the rooms.

After using such a compound, the structure becomes windproof, however, jute is used for additional insulation during construction. There is a possibility of cutting the remainder in the corner brackets. The notch must necessarily have the shape of a trapezoid.

"Into the paw"

A feature of this technology for installing wooden blocks is that it can be used to form both the corners of the building and T-shaped walls for rooms when constructing a building from glued laminated timber. For laying in this way, you need to make a hidden spike for fastening.

When designing an angle "in the paw", it is necessary to form an undercut, the presence of which distinguishes this method of attachment against the background of all the others. However, in this way it is highly discouraged to collect load-bearing walls, as their corners will be well blown. To prevent drafts, it is best to create a slope in both directions.

Another feature of joining a bar "in a paw" is the ability to create both a residual connection and a non-residual one.

For specialists, it is more preferable to connect the walls with the removal of the ends of the beams, but you can also carry out installation with the rest with your own hands.

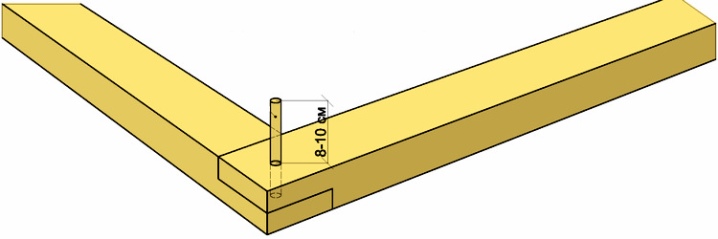

For fastening "in the paw" it is necessary to cut out a groove in which the perpendicularly located material is fixed. To increase strength, you can use pins. Such beams fit into "half a tree".

"Half a tree"

When using this method, the crown is laid out from pairs of beams. The corner element looks like this: the top half of one bar has been removed, and the second bar does not have the bottom half of its array.

For to carry out such an assembly, it is necessary to extend the corner holes on the connections to the dowel. It should be such that the required number of beams could be connected without any problems. After mounting the initial crown on the foundation, connected by wooden dowels, you need to lay the sealing material. After that, they begin to lay the next crown.

As soon as the angle of the joints of the second crown is fixed, the rows of beams begin to rally together. To carry out rallying, you need to use pins. After 1.5 meters in height, holes must be drilled from top to bottom to drive them. It is necessary to hammer the elements so that they go inside one and a half crowns. However, three crowns can also be sewn together. This can be done if there is a deep hole drilling tool and wooden dowels of suitable length.

With all the advantages of half-tree connections, they also have a significant drawback: blown corners. To level it, it is necessary to insulate the corners with wood dowels.

Connecting internal and external walls

Quite often, in houses made of wood, there are internal partitions, as well as interior walls made of the same timber. This is a pretty good scheme that fits seamlessly into the interior. In addition to external beauty, such structural elements also have a number of practical advantages. So, the internal timber wall has great strength and density, and also boasts of its sound-absorbing properties. For the manufacture of such an element, you can use lumber with a thickness of 10 centimeters. Such a choice will give the wall the required margin of safety and resistance to high pressure.

To connect the inner wall to the carrier, all the same grooves and spikes are used. At the same time, you can worry about this issue in advance and put vertical bars in the necessary places in order to use them as a tee. If this is not done, then the grooves are cut out already in the inner part of the crowns, and spikes are cut out in the beams of the future partition or inner wall. In order for the inner wall to be even and strong, its elements must be fastened together with wooden dowels.

Recommendations

When cutting out a doorway, the wall ends of the beams should be fastened with solid boards. This will prevent them from being pulled in or out.

When cutting out window openings and assembling boxes, you must in any case leave a gap, which is designed to compensate for the shrinkage of the log house. Its size ranges from 5 to 7 centimeters. An expansion gap is also left above the upper cold end. The formed void is filled with a soft insulation material. Doorways are made in the same way.

When making corners, it is necessary to constantly and carefully check their height and verticality. Any deviations must be eliminated in each crown, even if this occurs at the cost of replacing a full bar. The height is adjusted by using the thickness of the spacer in the sunken corners. In this case, a simple, popular solution can also work: on a high angle, you need to knock on a bar with a sledgehammer. Then he can stand in the groove all the way, which removes the unnecessary difference in height.

The straightness of the wall to be assembled must be determined using a plumb line, and the horizontalness of the walls or the upper edges of the timber should be checked using a building level.

Many methods of joining the beams have a common disadvantage, which is that the formed corners or longitudinal attachments are blown away. To level this problem, it is worth using an insulating pad. Previously, it was made from moss or a skein of linseed tow.

Now, specialty stores periodically replenish their assortment with cushioning materials such as flax or flax. In extreme cases, you can play on polyurethane foam.

It is highly recommended to drill the beams on the upper rims, having a solid support underneath. For these purposes, flooring, scaffolding or scaffolding can be used, but not the wall itself. It is dangerous to use as the drill of a heavy duty construction drill can get stuck during the drilling process, knocking the carpenter off balance and likely throwing him off the wall.

For more information on how to connect the timber, see the video below.

The comment was sent successfully.