All about plasticizers

Plasticizers are special additives based on polymers. They are added to the concrete mix, helping to improve the physical and chemical properties of the working mass and its performance. They are used in the construction industry and during repairs. Plasticizing agents are produced in a wide range, they have different compositions, differ in purpose and principle of action.

What is it and what is it for?

Plasticizing additives - liquid or powdery substances for cement and concrete mix. Most of their modifications have a low percentage of volatility, excellent compatibility with any building materials. Many formulations are odorless (with the exception of sulfite-alcohol based solutions).

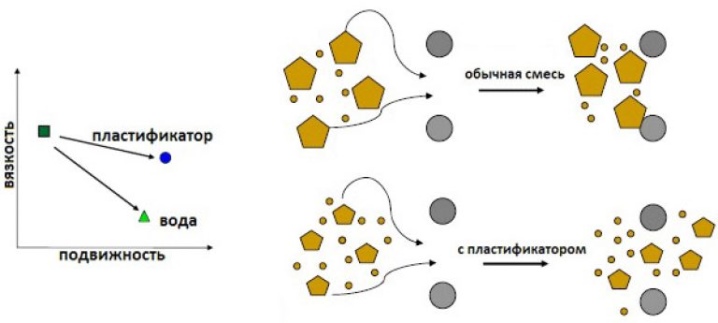

The use of plasticizers improves the mobility and flowability of the cement mass. The mortar made using traditional technology is thicker. Such a mass is inconvenient to use. Additional introduction of water into the solution leads to an increase in its mobility, however, the frozen structure will become brittle and prone to cracking. The addition of plasticizing agents improves the fluidity of the cement mass without deteriorating the physicochemical properties of the hardened concrete.

Plasticizers are also used for:

- increasing the adhesion of concrete mortar to reinforcing elements and various building materials;

- reducing the number and size of air pockets in a monolithic concrete structure, which are often formed when the solution hardens;

- ensuring the homogeneity of the mass;

- reducing the volume of cement consumption up to 20%;

- increasing the strength of the concrete structure;

- reduction of shrinkage;

- increasing the strength and moisture resistance of concrete;

- reducing the risk of cracking on the concrete surface.

It is recommended to add plasticizing additives when using “stale” cement, if it is necessary to extend the terms of using the cement mass.

The high cost is attributed to the lack of products, which is why the cost of concrete mortar rises. Another disadvantage of such additives is the need to make accurate calculations when dosing components. If mistakes are made, the cement mass will not meet the characteristics declared by the manufacturer.

Species overview

Plasticizers for cement are classified according to several criteria. They differ in composition, purpose and a number of other parameters. To select a suitable substance, you should study in detail all types of additives offered by manufacturers.

By composition

Plasticizing additives are organic and inorganic. Some of the safest and most environmentally friendly substances are considered, in the manufacture of which various polymers and silicones are used. These solutions have no odor, so they are often added to the cement composition for construction and repair work indoors. The action of silicone and polymer additives is aimed at improving the mobility of the mixture and increasing the water-resistant qualities of the finished concrete.

The next type of plasticizers is made on the basis of surfactants. They are made from technical lignosulfonates.Due to these components, the additives help to reduce the consumption of cement mass, increase frost resistance and increase water resistance.

The last type is additives that include polycarboxylate components. Such plasticizing agents are recommended for use in the construction of various massive monolithic structures. The polycarboxylate composition increases the shelf life of the finished working solution.

By appointment

There are narrowly targeted plasticizers on sale. As a rule, these are mono-additives with one property.

- With accelerating action. Such plasticizers help accelerate the process of hydration of the cement slurry. Most often they are used when filling artificial reservoirs, swimming pools.

Accelerating additives are recommended for use at low temperatures.

- Retarding plasticizers. These additives contain components that slow down the rate of hydration of the finished concrete mass. It is advisable to use them when transporting the solution over long distances.

- Antifreeze. Formulations for use in winter. They help to increase the frost resistance of the working mixture. Thanks to the introduction of antifreeze additives into the cement mortar, it is possible to work with concrete at temperatures up to -25 degrees while maintaining the operational properties of the finished concrete structure. The action of the plasticizers included in this group is aimed at abundant evaporation of moisture during the maturation of the solution.

- Air-entraining. These types of plasticizers increase the resistance of concrete to extremely low temperatures. Once in solution, they cause a chemical reaction in which there is an abundant evolution of oxygen. The formed air bubbles are evenly distributed throughout its volume when the mixture is stirred. The hardened concrete mass with the use of an air-entraining plasticizer will resist cracking in the cold.

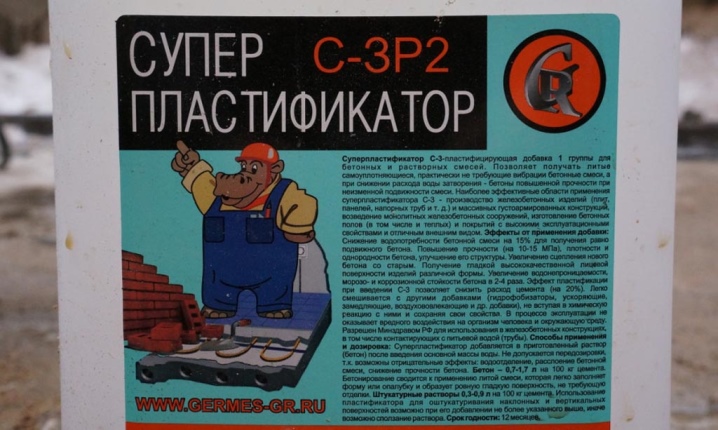

In addition to mono-compositions, manufacturers offer multicomponent superplasticizers... They contain several active substances, due to which they have a multidirectional effect.

By the strength of the action

Plasticizers are divided into 4 groups. On sale there are "weak" additives intended for the construction of small-sized structures. They are made on the basis of organic components.

"Medium" effect plasticizers are intended for laying the foundation... They contain lignosulfonates, which increase the mobility of the finished solution. Thanks to this feature, they help to enhance the waterproofing properties of the foundation.

"Strong" additives are made from acrylates and lignosulfates. They increase the plasticity of the concrete mass from P1 to P4. Contribute to improving the stacking of the mixture during vibration.

It is recommended to use them for putty, screeds, paving stones, strip foundations.

Supplements are also "super potent". Their production requires sulfuric acid, naphthalene and formaldehyde. Plasticizers based on these components increase the plasticity of the solution up to P5, without reducing the strength characteristics of the finished monolith.

Popular products

Manufacturers offer a wide range of plasticizers for cement. The following types of supplements have proven themselves best.

- Sika Sikament BV-3M. Universal plasticizing agent for working with cement mixtures. Thanks to its use, material consumption is reduced, and its quality is improved. The additive is available in liquid form in 5 and 1 liter canisters.

- Superplasticizer Cemmix CemPlast for plastering the surface, for arranging screeds and installing underfloor heating.Promotes an increase in the mobility of the cement composition, significantly reduces the labor costs associated with the processing and laying of concrete. Liquid additive Cemmix CemPlast is packaged in 5 and 1 liter plastic canisters.

- "Anti-frost" from the "Plitonit" company. It is a brown liquid, hazard class 4. Manufactured in accordance with GOST 12.1.007. In production, lignosulfonates and salts of inorganic acids are used. The additive is recommended for use at negative temperatures not lower than -25 degrees.

- Isomat Plastiproof - waterproofing plasticizer for concrete from a Greek manufacturer. The latex-based liquid additive helps to increase the waterproofing of the finished concrete structure and the plasticity of the mortar.

Compatible with all brands of Portland cement.

Domestic and foreign manufacturers offer plasticizers not only for cement mortars, but also for polymer masses intended for:

- casting of plastic and PVC products;

- manufacture of rubber, various sheet materials;

- production of films, linoleum and other products.

The addition of such substances helps to improve the technical characteristics of the finished product, as well as its performance.

One of the most popular drugs is DOP (dioctyl phthalate). It is a chemical substance for polyurethane and polyvinyl chloride. DOP is a toxic liquid that can ignite when heated and form corrosive vapors. The substance is of the highest, first and second grades.

The next popular plasticizer is DBP (dibutyl phthalate). It helps to increase the elasticity of the casting, which leads to the stability of the finished product to various types of mechanical stress. The liquid additive is used for cold porcelain and polymers.

It is widely used in the production of paints and other paints and varnishes, nail varnishes.

Popular plasticizing additives include dioctyl adipate (DOA). It is often used in the manufacture of various PVC products. The substance is non-toxic, due to which it is used in the production of some finishing materials, films for food packaging.

Popular plasticizers for soft PVC include DINP (diisononyl phthalate). It is slightly volatile. It is a liquid, colorless, odorless substance with low perspiration.

Thanks to the use of the additive, manufacturers produce PVC products with good frost resistance.

Where are they used?

Plasticizers are used in the construction industry for work inside or outside the premises. They are added to the concrete mass when laying various types of foundations. When using specialized additives, a denser and stronger cement structure without air voids is obtained.

The use of plasticizers is relevant in various fields.

- For plastering. The mass is made from cement, lime, gypsum, water, filler and other components. The finished solution is heavy, thick and inelastic. With the addition of a plasticizer, DSP (cement-sand mixture) becomes more "pliable", convenient in use and economical in terms of consumption.

- For paving slabs. Such products are used for paving garden paths, sidewalks, landscaping parks, for decorating personal plots and for other purposes. The tiles are made on the basis of cement, sand, water, gravel.

The addition of plasticizing additives helps to increase the mobility of the mixture and increase the resistance of the solution to sudden temperature changes and frosts.

- For grouting. Thanks to the addition of a plasticizer to the grouting mixtures, the formed joints become more abrasion resistant and less prone to contamination. The mass with additives becomes absolutely moisture resistant, it is not susceptible to damage by fungi and mold.

- For tile adhesive. Plasticizers make the mass more convenient to use by improving its adhesive properties. Masonry glue with improving additives can be used for different types of tiles, while any building material can act as a base.

- For clay in order to improve its binding qualities and compensate for the deficiencies of the clay mass (for example, rapid solidification, cracking).

Plasticizing additives are often used when laying floor screeds. Their use allows you to save building material, to obtain a high quality flat base without air pockets, cracks and other defects.

How to use it correctly?

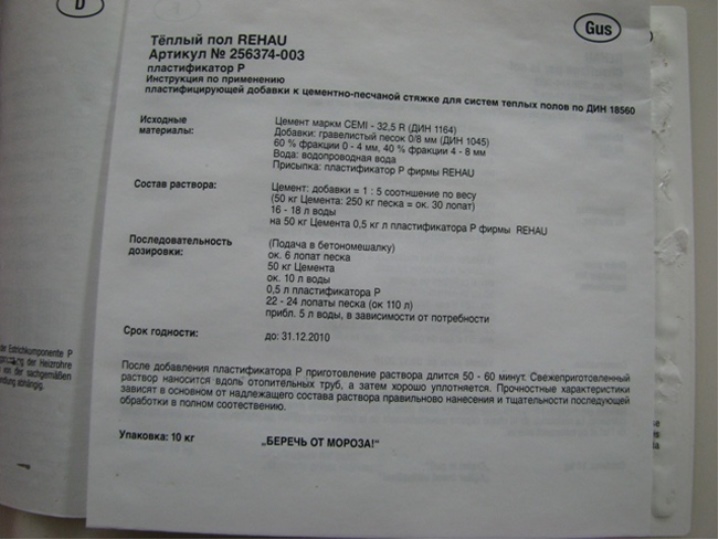

It is necessary to use any kind of plasticizers in strict accordance with the instructions from the manufacturer. Otherwise, the quality of the working mass or ready-made solution may deteriorate.

General recommendations:

- adherence to a strict proportion of ingredients (the dosage of the plasticizer is indicated by the manufacturer on the package);

- using a clean container for diluting the solution;

- production of the working mass at a positive ambient temperature;

- use of personal protective equipment while working with plasticizers;

- breeding far from sources of open fire.

Before use, you must first dilute the additive in water. It is not recommended to use expired plasticizers. Compliance with the technology for the production of the solution, dosage and rules for the use of the plasticizer contributes to obtaining a mixture that is easy to use with excellent technical and operational qualities.

The following video will tell you even more about the concrete plasticizer.

The comment was sent successfully.