Drilling concrete with diamond core bits

A diamond or victorious core drill is the only way out for craftsmen who, decades earlier, needed a massive drill of the same diameter, sometimes weighing more than a dozen kilograms. The drilling crown-drill with a 10 cm working section made drilling in an uncomfortable position or at a high height much faster and more efficient.

Features and scope

The diamond core drill is used in places where the use of standard high-speed steel or even pobedite alloy is significantly complicated by the presence of clay bricks, high-strength reinforced concrete for reinforced foundations and floors of buildings. It helps the master in the case when concrete products contain a reinforcing mesh with rods more than a centimeter thick.

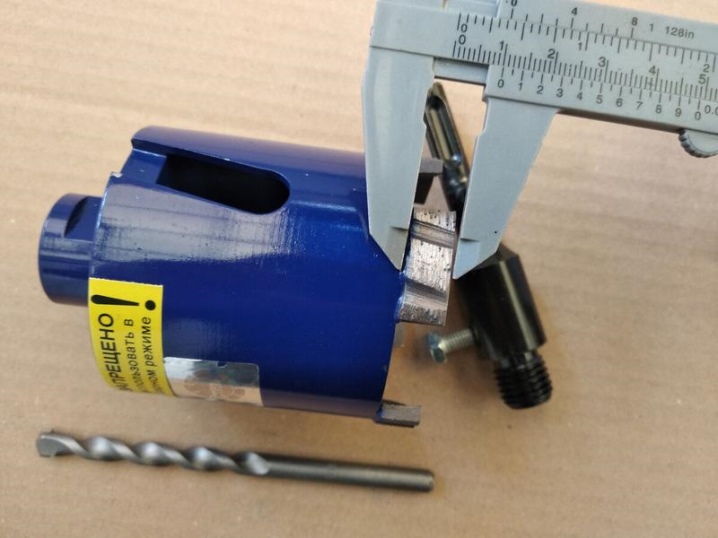

A crown is a composite tool that includes a hollow cylinder with a cut end face, on the face of which a layer of diamond is applied or won.

In the center there is a master drill (concrete drill), which is removable. Such a drill (short in length) is easy to purchase at any hardware store. But there are also crowns with a fixed drill, the breakage of which will significantly complicate cutting a hole in a strictly specified place.

The main structure - a piece of pipe and the base of the center drill - are made of high-strength tool steel. Will win and / or the diamond is only on the cutting (punching) edges. A drill made from a single piece of pobedit or a diamond would cost ten times more expensive than existing counterparts.

Low-strength concrete, from which non-reinforced non-bearing partitions are made between rooms of the same apartment, can also be drilled with pobeditovy alloy. Natural stone (granite, basalt) in non-shock mode is nevertheless crushed and cut with a diamond drill, the same applies to unhardened glass. Any brick is processed in percussion mode with a victorious crown - in this case, buying a diamond (of the same diameter) is unjustifiably expensive.

An exception to all these rules is tempered glass, which, although it is crushed with a diamond tip, at the slightest attempt to process the material immediately crumbles into small crumbs with dull edges.

The scope of application of victorious and diamond crowns is the laying of electrical and electronic communications, water supply lines, heating, hot water supply and sewerage.

A typical example is any apartment building: without a diamond crown, a sewer pipe (up to 15 cm in diameter) cannot be installed on all floors where toilets are located one above the other.

The field of application of the crowns is drills and perforators of any power, hand-held drilling mechanisms. Holes, in addition to through holes (for laying utility lines), are drilled in blind versions: recesses for cut-in sockets, switches and automatic fuses, meters, built-in sensors, etc. Overhead (not mortise) electrical appliances do not require corona drilling in the wall.

Drilling of foam and gas blocks, wooden walls, composite, plastic partitions and ceilings is performed with simple HSS crowns. They do not need a diamond or a victorious tip.

Types of drill bits

Drill bits differ in the range of diameters. He also defines their specific purpose in each area of application.

- 14-28 mm - differ in a step of 2 mm. These are 14, 16, 18, 20, 22, 24, 26 and 28 mm. Rare exceptions include values, for example, 25 mm. Diamond bits with a small value - up to 28 mm - are used for drilling holes for chemical anchors. The latter are used for the construction of flyovers, bearing supports of large-sized machine tools and other heavy structures. Chemical anchors require a drill bit that is at least 4 mm larger than the stud itself. Failure to comply with this requirement, the chemical anchor will not provide an adequate margin of safety.

- 32-182 mm. The step is 1 cm, but the number ends with the number 2. The exception is sizes 36, 47, 57, 67, 77 and 127 mm. The size (diameter) of the working part of such a drill has a "round" size, for example, 30, 40, 50 mm. In this case, the "extra" 2 mm - one on each side - build-up to the side by 1 mm. Without 1mm spraying, which is the diamond layer, the crown would not perform its functions. For example, 110 mm is actually 112 mm - taking into account the high-strength cutting layer.

- Oversized crowns - 20-100 cm - do not have a uniform pattern in the range of values. The diameter step can be equal to either 25 or 30 mm. Typical sizes are 200, 225, 250, 270, 300 millimeters. The larger ones are 500, 600, 700 mm and beyond. In special cases, individual dimensions are used, for example 690 mm.

In addition to diamond, carbide (whole) crowns are used. This allows you to transfer the rock drill to the rotary hammer mode, which makes it possible to break the concrete layer, under which lies its more durable layer with reinforcement. The nozzle of such a crown wears out quickly (prematurely) under increased loads.

Crowns, which often fail at the most inopportune moment, require the strongest alloys in their composition.

For example, the working part has a serrated appearance, and the SDS shank fits most models of domestic and Japanese hammer drills used in everyday life. Such a solution is an option to quickly break through a concrete partition in an apartment under a small diameter, but these products do not differ in an increased service life. Due to the overstated impact force, the drilling quality suffers significantly.

Drilling methods

Depending on the characteristics of the wall or floor, dry or wet cutting of the material from which the partition is made is used. There are rules and recommendations that make it possible to get a long-term (and total linear depth of drilled holes) service life from the tool used.

Dry

Drilling (punching) "dry" is used in places where it is impossible to organize a temporary water supply channel. The crown must be located very precisely in the place of drilling: the slightest displacement during its operation will render the tool unusable. The shank and chuck must be lubricated. Lubrication will eliminate excessive impact friction that can lead to shank wear.

Dry drilling is used at facilities, in rooms where the equipment is extremely sensitive to moisture, and it cannot be turned off and moved, since the production process will be interrupted.

Wet

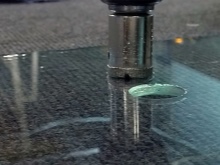

The essence of this method is as follows: a constant stream of water is supplied to the working area to cool the core drill heating up from friction. Water is pumped under pressure into one or more terrestrial atmospheres - but so that the spray from excessively high pressure does not interfere with the work of the master, does not fall on the perforator, which would cause the worker to receive an electric shock. Stopping the water supply will lead to rapid evaporation, boiling away of the liquid present in the working area - the crown will overheat and fail.

Attachment types

The lowest cost method is soldering. The cutting tooth or fragment is manually applied to a silver backing. Soldering gives a holding force of up to 12 Newtons during operation. At the slightest overheating, the silver layer melts and the fragment falls off. Supplied complete with water collector and manual water blower. So, for a crown of 12-32 mm per minute, up to 1 liter of water is required. Crowns up to a meter in diameter require up to 12 liters of water every minute. The relationship between water supply and bit size is non-linear.

Laser welding puts the drill bit production process on stream. Fragments are located perfectly evenly, with an even indent from the center of the working area.

Breaking strength - up to 40 N / m. As a driving force, there are special machines that cost a lot, which means that the crowns themselves are also not cheap.

Sputtering with a diamond layer is the most common. It is obtained by both soldering and wedging during sintering. Such products penetrate tiles, tiles, porcelain stoneware and ceramics. Sold as a set - a specific working diameter range corresponds to a specific set.

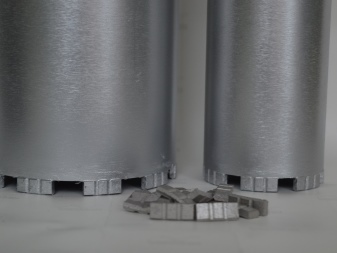

Restoration of the crown

Repair of the crown is a consequence of its wear, for example, when drilling steel. A worn cutting edge should not be reapplied. But it is possible to restore diamond core bits. First, the cause of the wear of the product is determined - for this, the crown is checked for horizontal vibration. With regular wear, new diamond particles are soldered in place of the old ones that have flown off. Buying a new crown is much more expensive than restoring the old one (perhaps 5 times per piece). The need for restoration is decided by the master. Restoration of a diamond crown is carried out according to the following scheme:

- the working area of the crown is cleaned of worn-out diamond particles and remnants of building materials scraped off at the point of work;

- with small horizontal beats, the bearing part of the crown is adjusted;

- in case of total wear of some part of the supporting structure, it is cut off, the remaining (shortened) section is cleaned in a new place to apply diamond particles.

After soldering a new diamond abrasive, the crown is checked for tensile strength, then painted.

A too shortened working part cannot be restored. Worn-out diamond inclusions do not lend themselves to build-up - they are replaced with new ones.

Frequent mistakes

First of all, the foreman (worker) observes safety precautions. He uses special clothing that does not pose a threat of tissue winding around the crown. A rough surface covered with a diamond layer is able to capture the material from which a protective suit is sewn. Requires protective gloves, a respirator and goggles that completely and tightly cover the upper part of the face.

The most common mistakes when working are as follows.

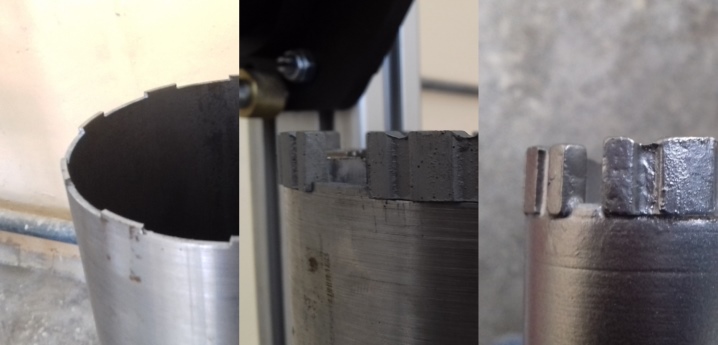

- The fracture or separation of the cutting tooth occurs mainly due to dry drilling or a stuck bit (jammed against a reinforcing bar).

- Abrasion of the nozzle in the area of the fragment adjoining - its sign is the changed color of the alloy. The reason is drilling without water, overheating of the bit, too fast rotation of the product at the point of work. For example, with frequent and long work on porcelain stoneware or steel, the crown becomes dull over time, both from exceeding the force and from overheating.

- A fragment that has tilted inward is formed when trying to bypass the standard hole diameter, abrupt start, lateral rubbing against the reinforcement.

- An element protruding outward indicates a too fast start, more than the required number of cutting fragments, exceeding the required drive power with worn fragments.

- Cracks and breaks on the product itself indicate an unacceptable load on the crown, including lateral impacts, horizontal beats (misalignment) of the entire product. The latter results in uneven wear of the crown, including wear of the nozzle walls.

- Dents on the crown indicate that the product was bent like an egg, it became oval. The reason is the sticking of the crown, strong blows to it.

Any other changes in the shape of the housing are due to excessive wear due to overloading.

See below for what diamond drilling in concrete looks like.

The comment was sent successfully.