Vibro-pressed tiles

Vibro-pressed tiles (paving slabs) are the latest development of European engineers.

Thanks to a special formula, it is possible to achieve the production of incredibly high-quality tiles with a high level of strength and frost resistance. It also has the correct geometry, so it is not at all surprising that it is gradually replacing the granite coating of European streets.

Advantages

- Low cost.

- Concrete does not create background radiation, unlike granite.

- A versatile material that can be given any size, color, pattern. Easy to work with.

- The rough surface makes it a very attractive material for winter use. Due to this property, it is practically non-slip, which is very important in our climate.

Production technology

First, a concrete mixture is made. A mixture for a tile or for a curb will differ significantly from a concrete solution that has a different purpose. The mixture must be hard, there must be little water in it. For good mixing of the mixture, a special planar concrete mixer is required. In addition, a computer is required to monitor humidity levels and determine readiness.

The next step is mold loading and production. With the method of vibrocompression, the mixture placed in the mold is pressed not only with the help of a press, but also with special vibrators. Through the use of such vibrators, it is possible to get rid of excess water and air. The mixture itself will be compacted as much as possible, which will give the product maximum strength, a high level of frost resistance and low water absorption.

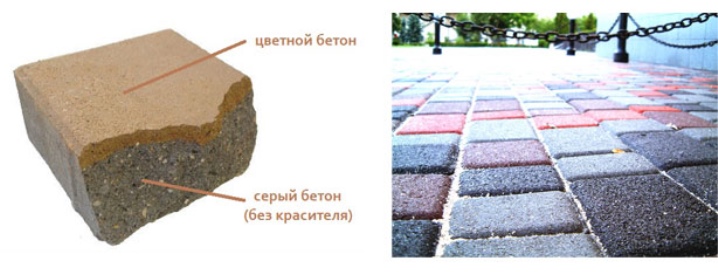

Colored tiles

Vibro-pressed paving slabs do not have to have the color of concrete. For this, European engineers have developed another special technology. So, during production, they mix two concretes at the same time: basic and facing. This is due to the fact that high-quality dye is a rather expensive pleasure. And its use is directly related to the final cost of the product.

The peculiarity of this method is that first ordinary gray concrete is poured into the mold, after which vibration is turned on. When it settles, the remaining place is filled with colored concrete, and the tiles continue to form. Due to this, it is possible to paint over about one centimeter. From this, neither strength nor other quality characteristics are lost, but at the same time the dye is significantly saved. Thus, it is possible to make the price affordable. A quality product can be used for many more decades.

The comment was sent successfully.