All about anchor brackets

Modern life cannot be imagined without electricity, but it requires the laying of self-supporting cables for the transmission and redistribution of electricity in overhead lighting and power networks. It is connected with the fastening of wires to poles and buildings, and such fasteners should be as reliable as possible. Anchor brackets paired with a clamp for cable lines are designed for strong fixation, eliminating breaks and sagging. However, they have found application in other areas as well.

Peculiarities

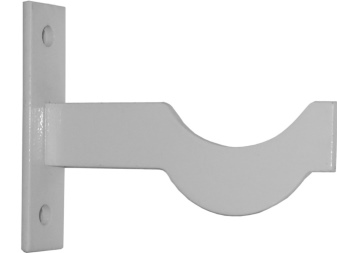

The anchor bracket is a metal monoblock or composite block and is needed to install the anchor clamp. Both devices are supplied in a set, their purpose is to securely fix the cable overhead lines on different types of poles. The essence of the installation comes down to fixing the bracket and hanging a clamp for self-supporting wires to it.

Let's consider the characteristic features of the anchor bracket:

- the element is made from high quality aluminum alloys with high strength;

- the product is resistant to mechanical deformation and can withstand heavy loads, including a high degree of tension;

- the material of the device is distinguished by its anti-corrosion properties, which make it possible to operate the part in different weather and climatic conditions;

- the bracket can be fixed to pivot, corner, end and walk-through supports, but it is also provided for its attachment to vertical surfaces: walls of various buildings, structures and buildings;

- fixing the part, as a rule, is carried out using a perforated mounting tape made of galvanized steel or by means of bolts (however, there are also elements that are fixed using quick-hardening compounds);

- there are locking pins on the fixing ring of the product, which ensure the limitation of the lateral displacement of the anchor clamp under lateral loading.

In addition to the fact that the brackets can be fixed to almost any surface, some of their types make it possible to mount without removing the bracket from the clamp.

Varieties

Brackets of this type are classified according to many characteristics:

- by their design, they are composite and monolithic;

- by material of anchors - polymer, metal and fiberglass;

- there are locking and non-locking products, as well as models that are fixed with a cement and polymer composition.

The most common types are as follows.

- Products CS 10.3 for laying trunk wires - these are high-strength, moisture-proof devices. Fix 1-2 anchor clamps.

- CA-1500 - a bracket that can withstand the maximum permissible tension of 1500 kgf. There is also a universal UPB device with the same tension index.

- Anchor brackets used in parallel with clamps, marked 4x16 mm, 2x16 mm, 4x25 mm, are needed for subscriber lines. In this case, these numbers mean the number of cores and the diameter of the wires. Such structures are not afraid of temperature extremes, corrosion, and the negative effects of UV rays.

A special flat type of anchor product is fixed with a plastic dowel, and it is intended for installation to the wall of radiators made of composite material (bimetal), cast iron or aluminum.

The radiator bracket calmly withstands the weight of the structure with water, does not deform under the influence of high temperatures. At the same time, it provides a secure fit without weighing the heating device down.

Technical requirements

Any types of linear reinforcement, which include anchor brackets, must comply with GOST standards. Here are the basic technical requirements for locking fasteners:

- service life - 10 years;

- shelf life - 2 years;

- bearing capacity in rocks of any hardness - 50 kN;

- fastener resistance in a compliant mode - 70-80%;

- ultimate tensile strength of rods for a steel anchor - 240 MPa;

- tensile strength - not less than 70%.

Specific requirements are imposed on the diameter and length of the anchor rod, including with the thread.

Also, the parameters of the standards are set for lockless types of devices, brackets with a chemical type of fastening and products from different materials. All these requirements must be met for safe installation and maximum long-term operation of the valve.

Application methods

The type of fastening of anchor brackets may differ depending on the purpose of the product:

- for fastening the self-supporting insulated wire clamp, the device is fixed with the F 207 mounting tape around the support in one turn, as well as with a bolt and one fastener (it is fastened to the wall with a metal wedge pin or screw);

- when placed on wooden poles and supports, drilling and fixing on a wedge anchor are preliminarily carried out;

- on concrete supports, the brackets are attached with strapping tapes with clips, quick-hardening solutions, but they can also be fixed on dowels and screws.

With the help of brackets, different in material, weight and technical parameters, it is possible to mount wall and floor heating batteries. For heavy cast-iron radiators, reinforced bracket models are selected taking into account the dimensions of the structure, complete with dowels. Simultaneously with them, special iron, threaded hooks of large diameter are used.

Aluminum and bimetallic batteries are mounted on similar smaller brackets.

Anchor bracket is a popular element for reliable fixation of communications, household appliances and pipelines for various purposes. But only a fastener that fully complies with these technical requirements and standards can provide a long service of these structures, which excludes accidents and malfunctions.

The following video is about the anchor bracket.

The comment was sent successfully.