Chemical anchors for bricks

Chemical anchors for bricks are an important fastening element that allows the necessary fastenings for heavy hanging elements to be fixed in the wall structure. Compositions for solid, hollow (slotted) bricks, liquid and others are produced. Before installing a chemical anchor in the wall, it is advisable to study in detail the recommendations for working with it, to select the appropriate components.

Characteristic

A chemical brick anchor is a multi-component connection consisting of a bolt or stud and a two-piece base. The polyester resin used in its adhesive part, after passing through the hardening stage, does not collapse under the influence of temperature fluctuations and other external influences, it can be used even in an aqueous environment. Since there is no negative effect on the base material, the installation of each of the fastening elements is allowed at a small distance from each other.

After the two components of the chemical anchor - resin and hardener - are combined, a chemical reaction takes place. The process of transformation of the composition from a liquid state of aggregation into a solid takes no more than 20 minutes.

The finished connection does not load the structure, avoids the occurrence of stresses and deformations in its individual sections.

When fastening, adhesion to the brickwork occurs, since the mixture of chemical components is as close as possible to it in its properties. Quartz sand with a fine particle size, with a cement binder is used as a filler in the resin. The adhesive base can be polyester, polyacrylic or polyurethane.

Varieties

According to the release form, all liquid types of anchors can be divided into 2 large groups. One is focused on local application, the other - on in-line installation, is used in a professional environment by repairmen, installation of stretch ceilings, finishing of buildings and structures. Each option is worth considering in more detail.

In ampoules / capsules

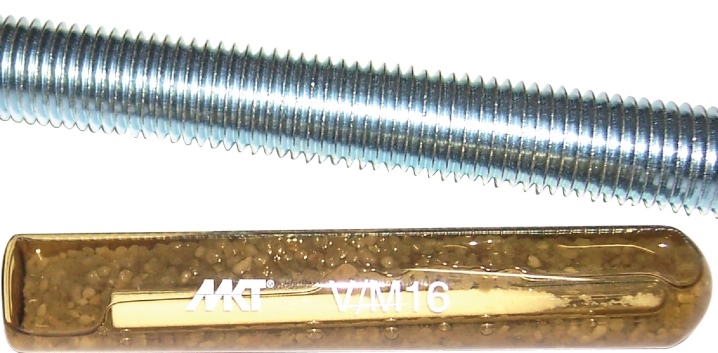

Designed for single use. Dimensional characteristics of the capsule correspond to the diameter of the fastener and the hole in the wall. The ampoule consists of two compartments, which contain a hardener and an adhesive base. It is placed in a drilled hole, when a stud or other fastener is installed, it is squeezed, the components are mixed, and the hardening process begins.

In tubes / cartridges

In this case, both components are located inside the overall package, separated by a partition compartment. The mixture for the chemical anchor is prepared in the process of moving the mass from the container body to the tip, then the prepared hole is filled with it, the fasteners are installed. Mixing attachment and extension must be included.

The choice of the form of release depends solely on the volume of work. It is easy to find on sale both ampoules and tubes with chemical anchors.

Popular manufacturers

There are many well-known foreign companies among the brands producing chemical anchors.

- German firm Fischer produces ampoules for RG, FCR-A studs, capsules for reinforcement fasteners, cartridges for a conventional sealant gun and a special mixer.

- Swiss brand Mungo specializes in ampoules, produces them in several lines and a wide range of sizes. Also in the assortment of the company there are cartridges of a special type for different nozzles of pistols, convenient for large volumes of work.

- Finland also produces chemical anchors. The Sormat company sells ampoules KEM, KEMLA, as well as ITH cartridges for 150 and 380 ml on the Russian market, the nozzle varies depending on the volume.

- German firms TOX, KEW are also popular. - their products are not so well known, but quite high quality.

Among the inexpensive brands are Polish Technox, Turkish INKA. The Italian company NOBEX produces exclusively injection cartridges.

Choice

When choosing a chemical anchor for hollow bricks, it is important to determine from the outset how much work is to be done.... 2-3 holes will be easier to fill with ready-made hollow material ampoules. If you need to hang heavy facade structures for a slotted type of brick cladding, you should immediately stock up on cartridges, since more than a dozen anchors will be needed.

Brand choice matters too. The cheapest will be Turkish and Polish compounds, but in terms of bond strength, they are inferior to both German and Russian counterparts. If you don't want to overpay, you can take the usual "Moment Fastener" or the Finnish Sormat.

The average price difference between Turkish and domestic brands is small. German and Finnish trains will cost twice as much.

The size of the package should be selected based on the tasks in hand. The capacities of 150ml cartridges come with a conventional tip like sealants. The 380 ml options require 2 separate tubes with a dispensing mixer at the end. Such packaging will last for a long time.

Installation rules

In a brick wall, chemical anchors are installed according to certain rules. Regardless of the chosen installation method, a marking is preliminarily applied, then a hole of the required diameter is drilled at a given point. It is important to use the drill in bumpless mode, since slotted and hollow baffles are easily destroyed by vibration.

When installing the ampoule, the order of attachment will be as follows.

- Hole preparation. Its diameter and depth should correspond to the parameters of the ampoule. After drilling, the remaining debris and brick fragments are removed manually or with a vacuum cleaner.

- Placement of the capsule. It goes deep into the prepared hole until it stops.

- Screwing in the stud. Under pressure, the capsule will burst, the process of mixing the components in its compartments will begin.

- Hardening. Polymerization takes from 20 minutes. The rate of strength development depends on the choice of components of the chemical anchor, the conditions for its installation.

When using formulations in cartridges, the procedure will be slightly different. Here, the chemical components of the base and hardener are reliably isolated from each other. They are mixed already during application, in special spiral nozzles, squeezed into the hole with a dispensing gun. Due to the special design of the cartridges, dispensing is automatic.

With this preparation method, chemical anchors can be used in holes of various shapes and diameters.

Stud anchors can also be combined with chemical anchoring. In this case, their meshes and bushings become additional fasteners. This facilitates the use of a detachable threaded connection, allows you to repeatedly screw in and remove a bolt or hairpin from the wall surface when dismantling the hinged structures.

How to install a chemical anchor, see below.

The comment was sent successfully.