Varieties and installation of anchor plates

One of the ways to install window structures is to install them by means of anchor plates. This is convenient, since the process does not involve removing the sealing filler and pulling the glass unit out of the frame, while fixing with self-tapping screws requires complete disassembly.

An additional advantage of using plates is the ability to carry out the work on your own, without resorting to the service of professionals.

What it is?

It is possible to purchase the necessary mount only with a good understanding of what constitutes an anchor plate. It is a flat metal piece with multiple fixing holes. As a rule, it is made of steel that has undergone a galvanized process, which protects the material from corrosion and other external influences.

The use of anchor plates offers a number of advantages.

- Allows the use of fasteners in high humidity.

- The plate is easy to disguise with decorative elements, a window sill or a slope, and it will not be conspicuous.

- It is not necessary to drill through the frame profile, as is the case with self-tapping screws.

- Metal parts reliably protect windows from strong wind and deformation caused by temperature extremes. This type of connection is the most durable and at the same time remains elastic.

- Windows are easy to level or slope.

- Hassle-free removal of fasteners if necessary - they are easily unscrewed. Possibility to select the fixation points at will.

- You can always reinstall the window sheet.

- Installation using plates is more economical in terms of time and costs - hardware has an affordable price.

Such a mount is considered ideal, when the window profile is mounted in a wall made of adobe, hollow brick, timber, that is, it has a loose base. However, it should be remembered that it is better to fix large window structures on special dowels through the frame profile, since the plates are not able to withstand their weight. That's why use is appropriate only for medium-sized windows.

Perhaps this is a certain drawback of the popular retainer, as well as the fact that it is better to use it in case of infrequent opening of the sashes or for a blind window. But if you needed to install a product of a non-standard shape, a polygonal, trapezoidal or arched model, instead of the usual anchor, it is always better to use rotary hardware.

Species overview

Today, you can find a large number of types of plates on sale with various fixing methods: with latches, toothed protrusions for fastening with bolts and self-tapping screws. When purchasing complex window systems, fixing parts with ears, designed specifically for their installation, are supplied with the products. Interchangeable, versatile parts are often included in PVC window kits.

The most common are two types.

- Swivel... Plates that are firmly fixed during installation by turning.

- Fixed:

- fasteners equipped with special rings for reliable grip;

- non-rotatable, installed at different angles and thus providing a strong fixation.

In addition, there are timber fasteners suitable only for timber window systems.... Anchor clamps are suitable for working with any wall covering, for plastic and aluminum structures without unpacking them, which is important if the installer does not have special skills.This method is much easier than mounting with bolts, and universal PVC products can also be used for doors, wooden frames, and other PVC structures. In contrast to the universal perforated metal strips, specialized parts with toothed fixation are highly reliable.

Various models of hardware with a swivel knot are especially in demand when it is not possible to carry out fasteners in the window opening itself. But without disassembling the glass unit and sashes, installation by means of plates is carried out from its outer side.

Dimensions (edit)

Usually, anchor fastening hardware is made of galvanized steel sheets, the thickness of which does not exceed 1.5 mm. For a window of standard size and shape, at least 5 plates are required: 1 - for the central part, 2 - for the sides, 2 - for the upper and lower parts of the frame. Details are marked with the thickness and length of the strip, for example, 150x1.2, but sometimes there are products on which you can see the distance between its "mustache". Then the marking will look like this - 150x1.2x31. The length of different models can vary from 10 to 25 cm, thickness - 1.2–1.5 mm, width - 25–50 mm.

The plates are attached to the window block using screws with a length of at least 40 mm and a diameter of 5 mm or more. For fixing to the inner plane of the walls, dowels-nails are used (length - 50 mm, diameter - 6 mm). For plastic structures, including for single-leaf, swing-out and other types of windows, it is recommended to use anchor plates. They are ideal for a 120 x 60 cm hot shoe. In most cases, you do not need to look for them additionally - they come with the window system.

Installation features

For a window block, fastening by means of plates is the safest, and metal parts can be hidden during the finishing process.

But before taking on an independent installation, you will need to study the rules for working with anchor plates.

- Fixation stiffness any metal bar is slightly smaller than anchors. If the window is blind, only the plates are sufficient. When installing a large product with heavy sashes, uniform load compensation is required, so you will not only need to insert the part into the groove and snap it into place, but also insure yourself with a self-tapping screw, which should go deep into the frame profile.

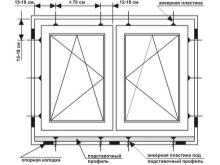

- Fasteners on the sides are mounted at a distance of 25 cm from the corners, in the upper and lower parts, and at the top, the connection is placed strictly in the middle. It is important to maintain an interval of at least 50 cm and not more than 1 m between the plates.

- Need to follow behind the correct bending of parts (only at an acute angle), which minimizes horizontal displacement and gives optimum joint rigidity.

- In the opening first you need to drill a hole for the anchor dowel, and then place it so that the wide neck presses the metal strip to the surface of the opening. To fix one piece, take 1 or 2 dowels 6–8 mm in size. Final fixation is carried out with a tapered locking screw.

- Despite the fact that the connection is further masked by the trim of the slope or plaster, it is advisable to make grooves up to 2 mm when preparing points for fixation - this will ensure that the plates are flush with the opening surface.

Consider the algorithm for installing a window system using the example of PVC products.

- Necessary free the window frame from the packaging film, after that it is necessary to remove the sash from the hinges, install the additional and connecting profiles.

- An accurate calculation is made, where the fasteners will be mounted. The plates are inserted into the frame and placed in the opening. The location of the points is marked on the wall with chalk or pencil.

- The frame should be pasted over from the inside and outside with mounting tape, vapor barrier and vapor permeable, to ensure waterproofing.

- The toothed elements of the plate ("feet") are inserted into the grooves on the profile at the required angle so that they fit snugly against the slope. Additionally, you can fix the part with a special self-tapping screw.

- Observing the distance from the anchor to the edge of 20-25 cm, screw all the plates around the opening.

- It is important that the correct fold of the fastener is present at two points of contact: to the opening and frame.

- Each plank should fixed with a self-tapping screw and twist through a plastic nozzle into a reinforcing profile. The hole depth should be 10 mm more than the dowel length.

- The frame is installed so that so that under each section of the structure and in the corners there are rigid seals. Thereafter, the structure is fixed vertically using mounting wedges.

- Before finally rigidly fixing the parts, it is necessary to adjust the position of the block by means of a building level.

Final work - creation of an assembly seam, moistening it with water using a spray gun, thermal insulation with polyurethane foam... It is advisable not to allow its overabundance. For this, you can use a vapor barrier butyl tape, construction sealing mastic. At the end, the slopes are finished - with a plaster mixture, facing stone-polymer tiles, facade materials. If you choose between two methods of installing windows, in the absence of experience, professionals advise using plates.

When using anchor dowels, additional help will be needed, the process itself will take a long time, and there is always a risk that the glass may be damaged. In addition, expensive equipment will be required - a high-power perforator and special dowels 10x132 mm. If a PVC window is fastened with bolts, then its depressurization is possible, in addition, with ignorance of the subtleties and improper installation, the geometry of the frame is violated, and it stretches over time.

In this case, there is only one way out - the structure must be reinstalled. Therefore, for self-assembly, it is more advisable to buy plates or to involve professionals in the work process.

In the next video, you will find the installation of PVC windows on anchor plates.

The comment was sent successfully.