Varieties and best models of electric rivets

The constant growth of interest in various models of electric rivets is due to the functionality and performance properties of this tool. It is designed for the fastest and at the same time high-quality fastening of parts. Most often, electric rivets are used when assembling structures, the elements of which are made of sheet materials. It should be noted that network and battery representatives of the model lines of leading manufacturers, having appeared on the domestic market, in record time were able to become more than in demand.

Description and scope of use

First of all, any electric riveter - it is a modern construction tool, the main task of which is the fastening of individual parts... Outwardly, this automatic unit is in many ways similar to the screwdriver familiar to many. At the moment, there is more than a wide range of models on the market that operate on a household power supply or rechargeable batteries.

Application in the framework of installation work of such a tool allows you to significantly reduce time costs and simplify the entire assembly process. It is also worth noting that, unlike manual riveters, their electrified counterparts do not require significant physical effort. When starting the device, uniform pressure is created on the shank of the rivet without any jerks. This contributes to the fact that the sleeve is tightened as smoothly as possible until the rod is biting off.

One of the key advantages of electric models is, of course, high quality of the created connection... At the same time, in the presence of physical strength and a certain practical experience, similar results can be achieved with the help of a manual (mechanical) riveter. However, the automated tool is designed to facilitate the riveting process. This is most important in confined spaces.

It should be noted that relatively recently, the described tool has a worthy competitor. We are talking about special rivet bits for screwdrivers and drills.

In terms of efficiency and productivity, they are practically not inferior to the riveters themselves, and at the same time they are much cheaper.

In fairness, it should be borne in mind that a specialized power tool still has one significant advantage. The fact is that these devices are equipped with containers for rivet shanks to be pulled out, which do not have to be removed manually. This in itself significantly increases the productivity and speed of installation. It is important that the specified waste does not fall on the floor of the workshop. However, despite the indisputable advantages, not all models are equipped with such containers.

Electric rivets are used wherever rivets of various types are fasteners. Most often, we will talk about the assembly of structures and their individual elements, the parts of which are made of sheet materials. By the way, it can be not only metal structural elements. Today, this type of tool has found application not only in construction, but also in the furniture industry and the automotive industry.

Advantages and disadvantages

The use of networked devices and running on batteries has a whole list of undeniable advantages.

- Performance work requires minimum physical effort.

- The equipment is characterized by maximum performance and efficiency. Within a minute, such a device is capable of installing up to 10 rivets, which is a key performance indicator when performing large volumes of work.

- High quality representatives from the leading manufacturers' ranges are capable of installing up to a million rivets. Timely maintenance and replacement of wearing parts will greatly extend the life of the equipment.

- Many models are designed to work with hardware products of different diameters. A similar tool, including battery-powered models, is equally successful in installing rivet nuts, studs, pulling and threaded fasteners.

Speaking of the cons, first of all it is worth focusing on the need for a power source. In this case, we are talking more about network devices. This disadvantage is completely eliminated when using battery models. Their main advantage is, of course, maximum mobility. According to the declared characteristics of most manufacturers, one battery charge is enough for at least 400 operations. At the same time, the presence of an additional structural element increases the mass of the tool.

Species overview

In accordance with numerous reviews from ordinary users and experienced professionals, electric riveters have long become indispensable helpers. And in this case we are talking about performing installation work in everyday life and in the conditions of small workshops, as well as on an industrial scale.

Taking into account the scope of application, all existing equipment modifications can be divided into several main categories.

Household

At home, both mains and battery rivets can be successfully used. However, the second option will often be much more convenient. For example, a tool that is not tied to the network will become indispensable when performing roofing work. The main distinguishing feature of household (amateur) riveter models is the maximum simplicity of the design, the main element of which is a rotating head. Their advantages include:

- ease of operation and the need for minimal effort;

- riveting speed;

- impressive safety margin of equipment;

- the ability to install rivets of different sizes.

Professional

Industrial models of electric rivets are modern type of tool with a wide range of applications... Such devices allow you to install various types of fasteners with a fairly wide range of diameters (as a rule, this parameter ranges from 2.4 to 6.4 mm). We are talking about such hardware products as blind rivets, threaded rivets, rivet nuts, and studs.

Professional models of power tools differ from their household “counterparts”, first of all, by their increased power. An equally important point is the main performance indicators, and, first of all, high productivity. It should also be remembered that such models are more weighty and overall. They also differ from amateur ones in cost..

Packing

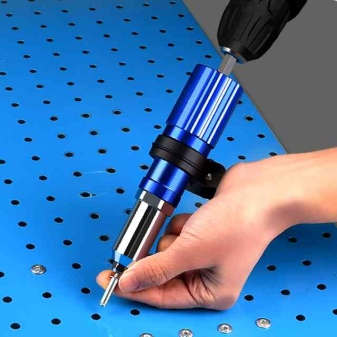

Above, we have already mentioned attachments for screwdrivers, the popularity of which continues to grow at a record pace. This device is easily and quickly installed in a standard power tool holder. After such modernization, it can be successfully used for:

- assembly of furniture;

- performing work in a car repair shop;

- installation of ventilation systems, air conditioners and other structures.

Naturally, this is far from a complete list of the possibilities of packed rivets. Such attachments are versatile, since they can be installed in the holders of most models of cordless and cordless screwdrivers and drills.

The operating voltage and torque of the latter can be between 10.8 V and 11 Nm, respectively.

Popular brands

At the moment, a fairly wide selection of models of both household and professional models of electric riveting equipment is presented in the corresponding market segment. On the one hand, this allows you to choose the most suitable option in each specific case. However, some may have some problems with this variety. The current ratings of the most popular brands and models can come to the rescue. So, now the following well-known brands can be distinguished.

- Time-Proof - a manufacturer from the Middle Kingdom, specializing in the production of rivets. The model range of this brand, along with pneumohydraulic and reinforced hand tools, includes, for example, an electric riveting machine TAS-500 with unique performance indicators.

- Metado Is a trademark owned by the German company Metabowerke GmbH, under which power tools, pumping equipment and a wide range of accessories are produced. In 2015, the manufacturer became part of the Hitachi Koki Co.

- Messer Is a Taiwanese company that produces modern pneumatic and electric tools for various fields and industries. One of the main competitive advantages in this case is the optimal ratio of equipment price and quality. By the way, the latter meets all current standards.

- Toptul Is a brand representing the renowned company Rotar Machinery Industrial on the market. This brand deservedly occupies a leading position in the current ratings of the most popular manufacturers of rivets. Representatives of the lineup of this company have been available since 1994. Moreover, all products fully comply with ANSI, ISO and DIN standards.

In addition to all those already listed, it is worth paying attention to the riveting equipment of the Gesipa brand. The German company specializes in the development and production of professional equipment for the installation of blind rivets, as well as the hardware products themselves.

It should be noted that this riveting tool is used in the production of equipment of such famous brands as BMW, Audi, Porsche, Bosch, Siemens and many others.

How to choose?

In each case, certain criteria for choosing a power tool should be taken into account. The best option would be a riveter that will satisfy all the requirements of a potential owner and at the same time have an adequate cost. So, if the tool will be used infrequently at home or in a small workshop, then a simple model belonging to the budget price segment is quite enough. In such a situation, there is no point in chasing increased power, since the ideal option is a high-quality and inexpensive riveting tool with a good battery.

When choosing equipment for a workshop or frequent installation work of sufficiently large volumes, it already makes sense to consider more expensive models. We are talking about high-performance riveters capable of working with hardware products of different diameters. In this case, such characteristics as power, productivity and pulling force will already be at the forefront. Based on the characteristics of the operating conditions, it is worth considering models with indicators from 10,000 N.

When choosing battery devices, it is important to pay attention to the battery capacity, which should be at least 4 Ah.

Riveting process

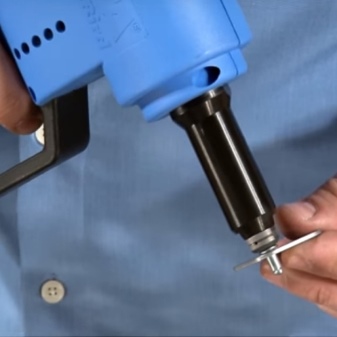

The principle of operation of the tool and the procedure for installing rivets itself can be understood by examining the device of the rivet. By and large, this is a kind of pistol with spring and lever mechanisms. The first, in the process of triggering, pulls in the rivet, and the second flattens it. The algorithm of actions is as follows:

- tight connection of the mounted parts and their rigid fixation;

- drilling holes of the required diameter, which should be slightly larger than the size of the hardware product;

- installation of rivets;

- installation of the desired head on the rivet;

- putting the tool on the rivet to the side;

- starting the device.

The riveting process itself is quite simple. The gripper, which is driven by an electric motor, pulls out the rivet shank. As soon as the limit mark is reached, the shank is sheared off. In rare cases, this does not happen, but if it does happen, then the procedure is repeated.

When analyzing the principle of operation of the described equipment, it is worth considering the features of the materials. So, the body of hardware products is made of soft alloys. The rivet shank must be made of steel. The strength of the connections depends on the length of the fasteners.

For information on what types of electric rivets exist, see the next video.

The comment was sent successfully.