Stainless steel fittings: characteristics and tips for choosing

There are many important components in a piping system. Stainless steel fittings play an important role here. With their help, pipes are connected to each other, branches are made, transitions and other manipulations are performed.

Experts note that in case of negative environmental influences, stainless steel fittings are the most successful choice for metal structures.

Key Features

Stainless steel fittings have the same functional characteristics as similar parts made from other materials. Polymer products have a lower price, but at the same time they can be significantly inferior in quality and reliability. Steel parts have their drawbacks, for example, they can be prone to corrosive processes, and this does not depend on how favorable the operating conditions were. Rust deposits are just a matter of time. Therefore, when working with water and heating systems, preference is given to stainless steel products.

Stainless steel perfectly tolerates the action of moisture and microorganisms. This helps her to serve without problems for two to three decades. Such fittings are used in plumbing work and are especially often used both on industrial pipelines and on civilian facilities.

Advantages and disadvantages

Like any part, stainless steel fittings have their own advantages and disadvantages. Before buying, you should familiarize yourself with them in more detail. Among the advantages are characteristics such as strength and durability of products. They are resistant to corrosive processes, and also tolerate the effects of most chemicals. The temperature range at which the fittings can be used is quite wide. In addition, they are available on the market in a wide range, and do not cause any particular difficulties during installation.

Among the disadvantages, consumers note the high cost of these connecting parts, as well as the fact that over time they still collapse. Of course, black steel fittings will cost less, but the service life will be significantly shorter.

Types and differences

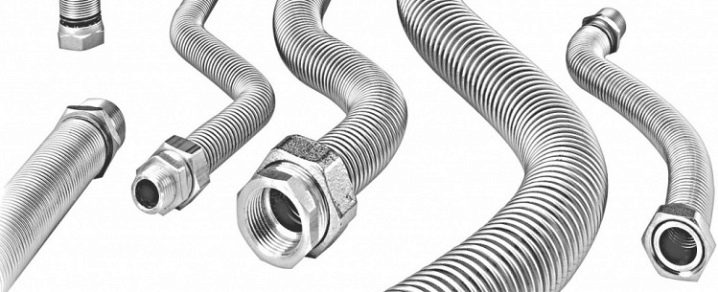

Stainless steel fittings can have different designs and, accordingly, different purposes. The assortment offered on the modern market is very wide. For example, a particular type of fittings can be used to connect a certain type of pipes. However, the most common division of these parts into groups is by the method of connection.

Depending on this, the following types can be distinguished:

- compression;

- welded;

- crimp;

- threaded.

The most widespread are threaded fittings. They are presented in a huge variety of options. These can be both standard elements that are used when working with end threads, and "American" ones that have two union nuts in the kit. The principle of operation of the parts is simple: the threads on the pipe and on the fitting are connected and simply screwed onto each other, and then tightened manually or with the help of additional devices.

Compression parts are similar to threaded parts, only more advanced. They have cone-shaped ends, as well as special seals and crimp union nuts. It is the seals that help get rid of the possibility of depressurization of the connection during further operation.

Welded products get their name due to the fact that they are fastened by welding. They have been used for a long time and are as widespread as threaded ones. They differ in reliable and airtight characteristics, provided that the welder has done his job correctly. The only drawback of welded fittings is that they can be installed with special equipment and experience in welding. In addition, after all the manipulations have been carried out, the pipeline branch will already become non-separable.

Special pliers must be used to install compression fittings. Most often they are used when working with metal-plastic pipes.

Varieties

Fittings, like pipes, serve to perform various tasks in the operation of utility systems. Therefore, they can be divided into several types. Couplings are used when it is necessary to connect straight pipe sections that are made of the same material. With the help of adapters, a transition is made between pipes, different in appearance. Elbows help to rotate pipes at an angle of up to 90 degrees, while angles - up to 180 degrees up, down or sideways. Crosses and tees are necessary in situations where pipe branching is required.

With the help of plugs, the ends of the pipes are closed. This can be done in the course of work. Flanges provide connection of any devices or tie-in fittings. Shut-off valves are necessary when you need to stop or, conversely, start the flow into the pipes. And the fittings provide a transition from a pipe to a flexible hose. They are indispensable in cases where you need to connect home appliances.

Leading manufacturers

There is a huge selection of stainless steel fittings and accessories on the modern market. This is undoubtedly an advantage and helps to evaluate the different options. Experts advise purchasing products from only trusted brands so as not to be disappointed in the quality of the product. Among the world's leading manufacturers, there are several companies that have earned a good reputation among consumers and guarantee the goods of proper quality.

The Spanish company Genebre started its activities in Barcelona back in 1981. It was originally a small workshop producing valves for piping systems. Later, the workshop expanded, turning first into a factory, and then into a huge company that won positive reviews from consumers around the world. The company has been manufacturing stainless fittings for about 40 years.

The AWH company has been operating in Germany for over 100 years, its products are well-known and in demand on the world market. There are about 40 thousand items in its assortment, while there is the possibility of making parts to order. Among the products made of stainless steel, one can note shut-off and control valves.

The history of the French company Eurobinox began its history in 1982, and today its products are presented in the sanitary ware markets. Stainless steel products under this brand include a variety of butterfly valves, weld fittings (polished or brushed), check valves, and threaded ball valves. Food grade fittings are also available.

And finally, another popular company, Niob Fluid, is from the Czech Republic. Products made of stainless steel are presented here in a large assortment. The basis is made up of fittings that can be used in the food and chemical industries.

How to choose and extend the service life

To select a fitting, the buyer will need to measure the size of the pipes, as well as know what they are made of. In order not to make mistakes in measurements, experts recommend using a caliper, with its help you can get the most accurate data. Even if you purchased stainless steel fittings from a reputable manufacturer, you must remember that the highest quality products need proper handling and care.Therefore, during operation, one must not forget about the most important rules.

First of all, you need to pay attention so that the transportation is carried out accurately, and the parts are not damaged in the process. This is especially true for the purchase of large quantities of goods. Each product must have a packaging that prevents the ingress of water. The transportation itself must be carried out in wooden boxes, which are securely fixed in the vehicle. In this case, the packaging must be protected from moisture and dirt.

In terms of storage, it is recommended that fittings are stored in a clean room with moderate humidity. During operation, stainless steel parts must be wiped with extremely warm water, since the use of detergents can harm the product. It can be concluded that it is not difficult to extend the life of these products, it is enough to follow the basic simple rules.

The main advice of experts is that the material of the fittings should be maximally combined with the material from which the pipeline is made.

In the following video, you will see a demonstration of press connections and pipe installation with Geberit Mapress Stainless Steel fittings.

The comment was sent successfully.