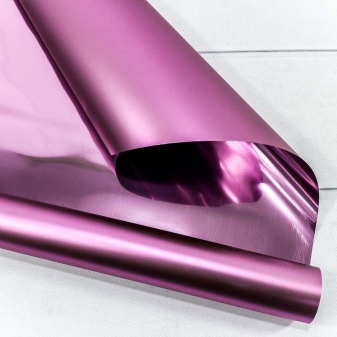

All about metallized film

Metallized film is used both in everyday life and in the food industry. Recently, its popularity has increased significantly. All this happens because this material has protective properties that help keep the products in their original condition for a long time.

Features and production

Metallized film is a base on one side of which aluminum is sprayed. A variety of polymer films can be used as the main material. The most common among them are polypropylene, which are abbreviated as BOPP. There are also polyethylene terephthalate films, abbreviated as BOPET. Slightly less often, both polystyrene and polyamide are used for manufacturing. The process of creating a metallized film is based on heating aluminum to a temperature when evaporation begins to occur. Usually it is in the range of 1600-1700 degrees Celsius.

To achieve such a temperature regime, it is necessary to put a piece of aluminum on tantalum, and then place it in a carbon crucible. Next, a high voltage current must be passed through it. After this, the evaporation process takes place. However, the most advanced option for the metallization of such a material is the use of spraying systems. It uses plasma, which is held by a magnetic field in specially made devices called magnetrons.

Many manufacturers use not only aluminum for metallization of films, but also silver, zinc and even gold.

If we talk about the properties of metallized films, then they have a surface that slightly resembles aluminum foil. Such products have both advantages and disadvantages. For a start, it's worth noting the pros.

- First of all, it is the protection of packaged products from exposure to light.

- Improvement of gas barrier properties.

- The products look more attractive.

- The cost of metallized film packaging will be cheaper than foil packaging.

- As for the gold-plated film, its advantage lies in the duration of use.

- The metallized film is environmentally friendly.

As for the shortcomings, this material practically does not have them. The only thing that cannot be done is to microwave products packed in a metallized film. Otherwise, it will not only spark, but also burn, and this can lead to the creation of a fire hazard.

In addition, if the film is even slightly damaged, all of its protective properties will not work. Therefore, when buying, you must definitely pay attention to this.

Varieties

Metallic films can be of several varieties, each of which has its own characteristics. Some of them can be flexible while others are rigid.

Flexible

These include polypropylene and BOPP films. 90% of them are used in the food industry for packaging various food products. This includes a package of ice cream, various snacks, and glazed curds. 10% is used for non-food products, for example, window bases, for cars.

Hard

Their direct purpose is considered to be the production of thermoformed packaging. These include blisters, confectionery containers of different shapes or trays made of laminated PET film.Besides, rigid films are used as decorative inserts or blisters for medicines. PET films have the best properties. They are not afraid of moisture, resistant to ultraviolet rays. Manufacturers produce such products with both matte and glossy surfaces. As for the main color, then most often it is either gold or silver. Among the new technologies, it is worth noting self-adhesive films made of natural gold, which are most often used for street advertising. However, to work with them, a person must know not only theory, but also have experience.

Since there is no polymer base in such a film, the effect of an old mirror will not appear in it. In addition, the gold layer is protected from contamination, which makes it possible to use such a composite for 14-15 years. However, this material has a fairly high price. Also, one cannot fail to note another option - this is a metallized laminated tint film. With its help, you can protect the glass of the car from ultraviolet rays, protect the interior from burning out, and also extend the life of some elements in the interior.

At first glance, such a film creates the effect of one-way visibility. But if a person looks from inside the cabin, then it seems transparent, since the entire view remains within sight.

Application

Metallized dense film is in high demand today and is used in various fields. It is used for tinting glass, for printing, for protecting windows from daylight, in electrical engineering and astronautics. Many people meet with some products made of this material in their everyday life. These can be rigid liners found in candy boxes, as well as confectionery containers or trays in which quickly perishable products are stored. In addition, metallized films are used to package meat or fish that are stored under vacuum.

Besides, some Christmas tree decorations, as well as garlands, are also made from a single layer of metallized film. It is also used to make gift wrapping for flowers and toys. In hot or cold weather, such films are glued to glass. Some experts use it in such an area as the production of capacitors. In the printing industry, some materials are made from just this material. Most often it is used for the production of full colors.

In an area such as construction, metallized film is laid when arranging a "warm floor", as well as when laying a water supply system. Here, it acts not only as thermal insulation, but also as waterproofing. Quite often, the material can be found in the decoration of offices, showrooms and even ordinary stores.

Summing up, we can say that such a simple material as metallized film is the most used material, as it is found in many fields of activity. The cost is not too high, but the effect of the application is huge.

In the next video you will find a brief overview of metallized BOPP film.

The comment was sent successfully.