Equipment for the production of paving slabs

The production of paving slabs can be a good option for your own business - it does not take much investment to open a workshop. At the same time, it is important to purchase the right equipment that will help to produce high-quality and durable goods that can provide its manufacturer with a decent reputation.

If you decide to produce tiles yourself, you will have to choose one of two methods of its production - vibrocasting or vibrocompression. The equipment in the two cases will be completely different, so let's consider what exactly is useful.

What do you need to make tiles by vibration casting?

For the production of paving slabs by the vibration casting method, a thick, but at the same time relatively liquid, concrete mass is used as a raw material. In short, the principle of manufacturing the goods is as follows: concrete is poured into special forms, and then the containers are placed on a vibrating table. The latter, vibrating, ensures proper compaction of the substance, so that no air bubbles remain in its thickness. Thus, the mass is compacted without the use of a press to the extent that, when solidified, the paving slabs are given the required strength and durability.

Let us clarify right away that Vibration casting is not the optimal way to produce paving stones. Despite the fact that the tile has a chance to get good, it will still have a fairly high water absorption coefficient and this will not affect the strength and durability for the better. Nevertheless, in independent home production, this particular method turns out to be cheaper and easier, therefore, individual owners choose it personally for themselves and even small provincial workshops.

Concrete mixer

You won't have to reinvent the wheel here - an ordinary concrete mixer working thanks to the principle of gravity will do for home use. You can buy one in any large hardware store and it will cost you inexpensively.

It is important to choose the right volume of the concrete mixer pear. If you really do not plan to open your own business, but just want to make paving slabs for your own yard with your own hands, a small volume is enough - it will be cheaper.

It makes no sense to buy a large concrete mixer for an amateur production - if there are not enough molds for pouring, the remaining concrete will be spoiled.

Forms

The essence of the production of tiles lies in the formation of concrete, so you cannot do without molds. To make the products varied and look beautiful in the set, it is advisable to take different molds - at least two types. Usually, experts advise not to experiment with the independent production of forms, because some of them will initially be defective, and the other part will not withstand the load and vibration, or will simply stick to concrete, making it impossible to extract the tiles. Without experience, you are unlikely to be able to make good forms by hand, so it is much more practical to buy them.

The most common mold making materials today are plastic, fiberglass and silicone.... Silicone pacifiers are more expensive than others, but they are considered the most practical and appropriate choice.

The fact is that, unlike competitors, they have a certain elasticity, so it is not so difficult to remove them from homemade paving stones. Before removing the finished products, plastic and fiberglass molds will have to be heated, and this, in principle, cannot be done instantly, especially at home, where heating will be possible only in small batches.

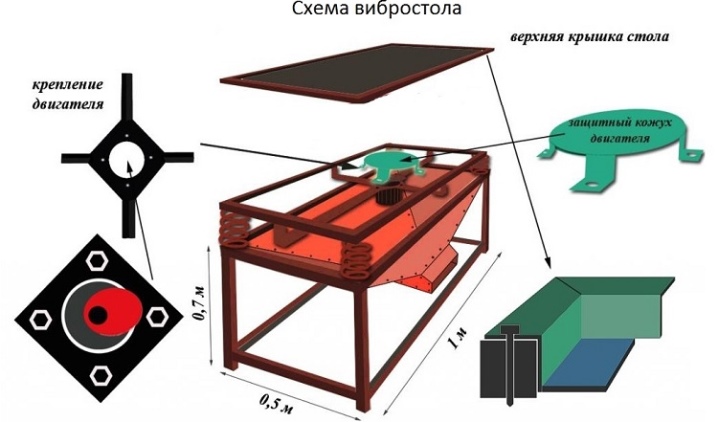

Forming vibrating table

Actually, the most important device for the production of paving stones, without which no production will work at all. It looks like a solid and reliable table top, which is movably attached to the bed. An engine is hidden in the thickness of the unit, which provides the countertop with continuous vibration - because of this, the installed forms with liquid concrete constantly tremble for many hours.

In such conditions, any air bubbles in the bulk of the liquid material rise to the surface. The resulting tile turns out to be dense and without extraneous inclusions, which has the most positive effect on its strength.

Heat chamber and shaking table

We said above that at home, many types of molds will be difficult to release from the contents without heating. At the same time, industrial enterprises, of course, do not do this on an ordinary kitchen stove, as you may have already intended to do - instead, they buy special equipment.

One of the options is a thermo bath - a special container with a constantly maintained high temperature inside. The forms placed in it quickly heat up and expand from this, so that the hardened concrete can be separated from them. The shaking table works on a principle similar to the shaking table's work - fine vibration is designed to break unstable joints, and such is the line of contact of the hardened concrete with the mold.

Equipment for vibrocompression

Vibrocompression is already more typical for large enterprises in the sense that the production of goods will require the purchase of serious equipment... However, this can be seen as an obvious plus - the molding process is fully automated. In addition, now you can already buy a manual mini-machine, which is much cheaper and can pay off based on the results of the production of even a small batch of products.

The fundamental difference between the production of paving slabs by the pressing method is that the concrete in this case is needed not wet, but semi-dry... Because of this, an ordinary gravity concrete mixer will no longer work for us - the thick mass inside will stick to it and stick to the walls, because of which no mixing really works. Anyone who wants to master this method of production will have to buy a more expensive concrete mixer with forced kneading.

Please note that this is not just a pear that rotates thanks to an electric motor, but a structure, inside which there are rotating blades, which provide approximately the same effect as a kitchen whisk.

Vibropress is usually regarded as a serious industrial equipment. - at least it has a built-in hydraulic system for a sufficient compression ratio and its own control unit. In this context, the hand press may be subject to the same criticism as the vibratory casting equipment - without a hydraulic drive, the pressing force will not be so impressive and this will inevitably affect the performance of the finished product. For this reason, a profitable enterprise should spend on a vibrating press - this investment should pay off over time.

To a person who has just learned about the existence of a forming vibrating table for the first time, a vibrating press may seem to them, since it is also a frame with a vibration motor. However, in this case, the equipment is more complex - it is supplemented with a pressure press, which is also equipped with a vibration motor.

If vibratory casting requires full-fledged forms for the production of tiles, then in vibrocompression only frames are used that resemble a honeycomb of the required shape.... Since a semi-dry mixture is used for production, which is not prone to spreading, it is poured into frames without a bottom, installed directly on the bed - the material will still not be able to leak out. After that, the frame is covered with pressure plates (in fact, with ordinary metal plates with decorative notches), and the load with the accompanying vibration from above is transferred to these plates.

It turns out that the semi-dry mixture in the frame experiences vibration both from above and from below - such an intense vibration allows you to completely rid the mass of the slightest inclusions of air. The fact that the substance is compressed under great pressure also helps to enhance the effect. Due to the fact that initially there was practically no moisture in it, it cannot evaporate and leave voids behind - which means that absorbed atmospheric or ground water cannot freeze in the thickness of the concrete product, which would gradually destroy the paving stones.

That is why products made by vibrocompression are considered more reliable, and the drier the mixture from which it was made, the better.

Acquisition nuances

Please note that the purchase of special equipment for the manufacture of paving slabs only for your own needs will never be the best option from the point of view of practicality - simply because the necessary equipment will not have time to pay off on such a small batch of goods. That is why vibrocasting at home is more popular than vibrocompression - a forming vibrating table can be designed even with your own hands from improvised materials, and its demolding version or a thermal bath will not be needed if silicone molds are used.

For the production of a vibrating table, an ordinary table is needed, which will not stand on the floor, but will hang in the air, being fixed on a homemade durable metal frame through springs or rubber gaskets. From the bottom side, any sufficiently powerful electric motor is attached to it, which inevitably gives vibration during operation - this is the technique and is ready.

With a vibrating press, the task of independent production is much more difficult - an extremely accurate drawing is needed, otherwise the drawing on the tile will be hopelessly damaged. In view of this, in most cases it is more practical to buy a vibropress, and not to manufacture it yourself - even if it does not pay off on meeting your needs, it can at least be sold in the future. Self-production of such equipment is fraught not only with catastrophic errors, but also with a huge amount of time, despite the fact that there is no particular financial savings.

The most serious disadvantage of the vibropress is that it is configured for the production of one specific type of paving stone, and the pressure plates in terms of surface area must exactly match the dimensions of the table. To make some completely different tile, you will have to demonstrate dancing with a tambourine - buy a new matrix block and start reconfiguring the unit. In many cases, it is so difficult for the layman that he prefers to give preference to vibrocasting - there the assortment is changed by simply buying a new mold.

The comment was sent successfully.