How to make a chipboard stool with your own hands?

A stool is a simple but very popular furniture design that is found in almost every home. There are a great many varieties of these items sold in stores, but it is quite possible to make them yourself at home. In this article, we will analyze in detail how to properly make a stool from available chipboard material.

Features of homemade stools

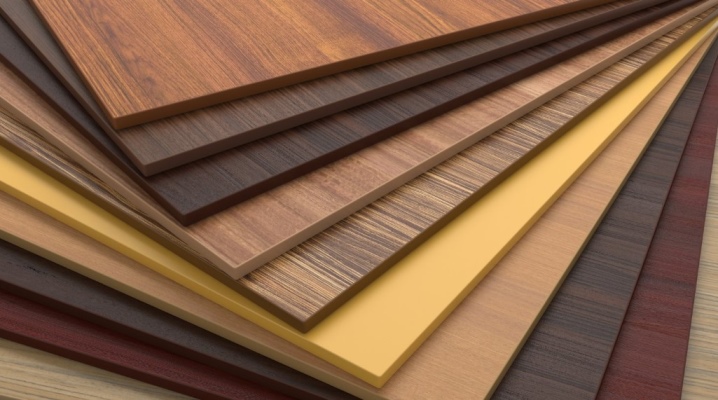

Most modern stool models are made from popular and inexpensive chipboard. It is an affordable material that is widely used in the manufacture of a wide variety of furniture designs. Chipboard "feels" great being inside the room. In such conditions, such structures do not undergo deformation or natural destruction, do not swell.

It is enough just once to look at a stool made of chipboard to understand that there is nothing prohibitively complicated in its manufacture. Everyone can easily cope with such work. The main thing is to have patience and all the necessary tools. The latter can be both professional and non-professional. Before starting all work, you should find out what are the main features of different types of chipboard. Let's get acquainted with them in detail.

- There are conventional particle boards. They are distinguished by impressive density, good bending strength characteristics. If you are going to make a stool in order to subsequently place it in the kitchen, then it is recommended to find a high-quality moisture-resistant material that will not deteriorate in such conditions. In the manufacture of ordinary chipboard, special additives are added to the chip mass, making it more wear-resistant and moisture-resistant.

- There is also laminated chipboard material. Chipboard is often used in furniture production and is found literally on "every corner". Laminated boards are distinguished by the fact that they are equipped with a protective top coating (decorative and protective layer), which significantly increases the technical and operational characteristics of the specified material. Chipboard is presented in a wide range of colors - you can choose the ideal option for an interior designed in any color scheme.

When planning to make a stool on your own, it is important to take into account the peculiarities of the selection of the ideal material. Let's consider them in more detail.

- An important thickness of chipboard sheets. On sale you can find specimens with a thickness of 8,9,10,16,18,19 mm. Experts recommend using materials with parameters 16 and 18 mm for the manufacture of furniture structures.

- It is necessary to take into account the external characteristics of the material: its color and structure. The stool should harmoniously fit into the environment and fully comply with it in all respects.

- The degree of processing of the edges is also important, as well as the level of environmental friendliness of the plates. All the cuts on the elements must be well poked around so that the chipboard does not emit hazardous and harmful substances (the composition contains formaldehyde resins that are released at high temperatures).

Required tools

Having good and reliable tools, it will be much easier to make a stool from chipboard, and it will not take much time. Consider a list of devices that you will need to carry out all stages of work:

- jigsaw (both standard manual and more convenient - electric);

- Ruler and pencil;

- building hair dryer (useful for end cuts);

- drill or screwdriver;

- special furniture stapler;

- drill (it is recommended to prepare with sweat);

- self-tapping screws or euro screws;

- PVA glue;

- a sheet of sandpaper.

All materials must be prepared: chipboard itself (or chipboard), and with it upholstery fabric or leather, furniture filler (foam rubber or synthetic winterizer is suitable). Having all the listed components, you can go directly to the process of manufacturing furniture structures.

Manufacturing

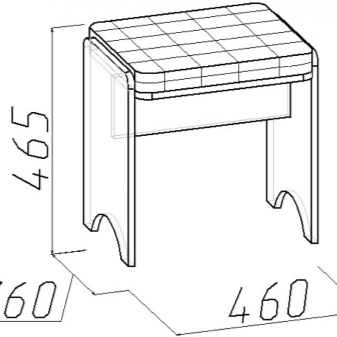

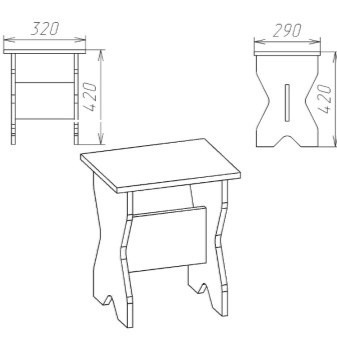

As mentioned above, there is nothing particularly difficult about making an inexpensive but attractive chipboard stool with your own hands. The main thing is to first draw up detailed drawings and indicate on them all the dimensions of the future structure. Having such an “action plan” in hand, it will be much easier and more convenient to work, because at any moment you can check whether you are doing everything right.

Material preparation and sawing

The first stage in the independent manufacture of a chipboard stool will be the preparation and sawing of the specified material that imitates a tree. Different craftsmen use different tools for this, but an electric jigsaw is considered more convenient and practical - it is easier to work with it. It is advisable to use a tool with short teeth. The jigsaw should work at the highest speed - only this way all the cuts will be clean and even.

Having at hand a template (a detailed drawing with all the details) of the future stool, you can proceed to creating it. A paper or cardboard blank must be attached to the wood boards, circled with a pencil. Thus, it will be easier for you to cut all the parts with high quality and accuracy. All small irregularities left after cutting should be removed with sandpaper or sandpaper.

The cut bars must be carefully sanded and tried on to each other. Grinding is especially important if small households will use homemade furniture in the future. Having prepared all the necessary details of the future design, it will be possible to proceed to the final stage before assembly - to drill all the necessary holes. Make sure they are all on the same level

Assembly

When all the parts have been cut out and prepared, you can proceed to the direct assembly of the stool. Before starting to assemble the furniture structure, it is necessary to process all cut edges with a special tape. It should be selected in accordance with the color of the material itself. Ribbons of contrasting colors are also appropriate.

The tape must be applied to the edges of the legs and seats, and then glued using a hot iron. The latter should be applied quickly with short movements. Press down the heated tape with a clean cloth. The glue on the back of the applied coating sets almost immediately - it will not heat up or cool down for a long time.

All parts of the stool must be assembled using self-tapping screws and confirmations. Some masters first glue all the parts, and then fasten them with self-tapping screws - it's easier. The seat of the resulting stool can be made soft by turning to the installation of foam rubber and upholstery.

Decorating

The stool will look more attractive when fitted with padding and upholstery. The upholstery of such furniture can be oilcloth, woven or leatherette. Each master himself chooses the best option. Foam rubber is often used as filling.

Useful Tips

If you decide to make your own stool from chipboard, you should check out some helpful tips and tricks from experienced craftsmen.

- Chipboard sheets do not have to be new. You can take parts from old, unnecessary furniture.

- When making a drawing of a stool, it is necessary to maintain a balance between its top and bottom, otherwise the furniture will not be stable.

- To work on a jigsaw, you need to put on a special lance with small teeth.

- The upholstery is the decoration of the stool; it is not necessary to resort to fixing it. Often this procedure takes a long time, but without this addition, furniture may look too simple.

- When sawing and adjusting all the details of the furniture structure made of chipboard, you need to be careful and accurate. Take your time to avoid damaging the stool or the surface of the material.

- Do not neglect the drawing up of templates, diagrams and drawings of the future design. With these components, all work will be much faster and easier.

How to make a stool with your own hands, see the video.

The comment was sent successfully.