Overview of starter profiles and their installation

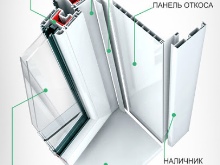

When installing plastic windows, doors and other structures, builders have to combine materials that are different in texture and composition. As a result, internal gaps and irregularities appear at the joints.

In places where a window or doorway adjoins the wall, it is most often necessary to carry out finishing work. In such a situation, the most convenient way to eliminate cracks is to seal the joints with ready-made window slopes. In the article we will tell you about the features of the starting profiles and their installation.

Peculiarities

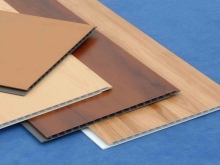

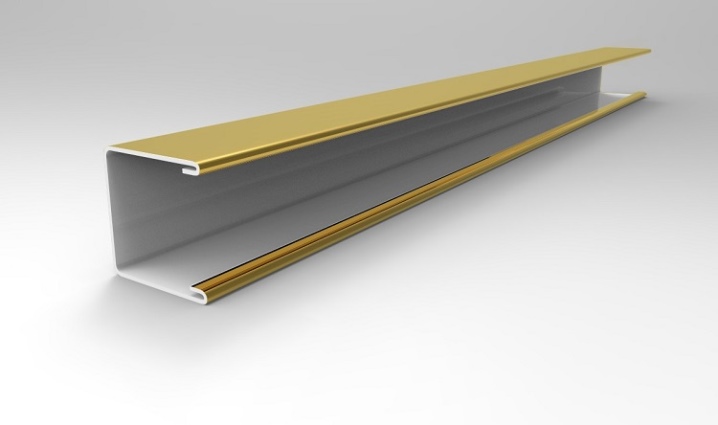

The design of the slope includes a number of elements, the main one being the starting profile. Starting profiles for window slopes look like double strips of various configurations, made of PVC or metal. Which type to use depends on the type of repair and finishing work performed and the density of drywall, the size and complexity of the structure. Drywall is a versatile material that is commonly used for interior decoration and decoration. It serves for correcting and shaping the design of the room, leveling surfaces. With the help of drywall, partitions are formed, false ceilings and arched openings are made.

Large parts of the covering in the interior must be securely fixed and held to the wall. For these purposes, durable and reliable carrier rails are produced. Stiffeners are fixed on the walls and ceiling, as well as around the entire perimeter of the room. Thin sheets with a density of 8-18 mm are especially in need of fixation.

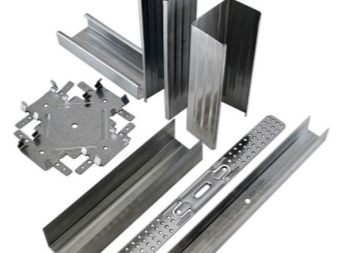

To work with drywall of all types, craftsmen choose fasteners made of galvanized metal, obtained by the method of cold rolling.

Materials (edit)

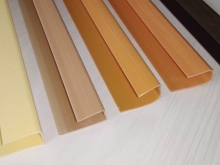

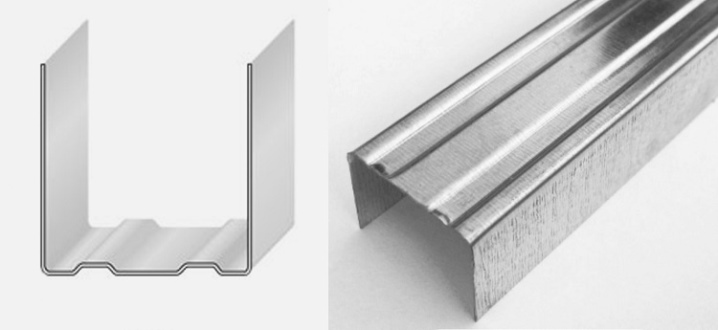

Profiles are made of metals and plastic.

Plastic

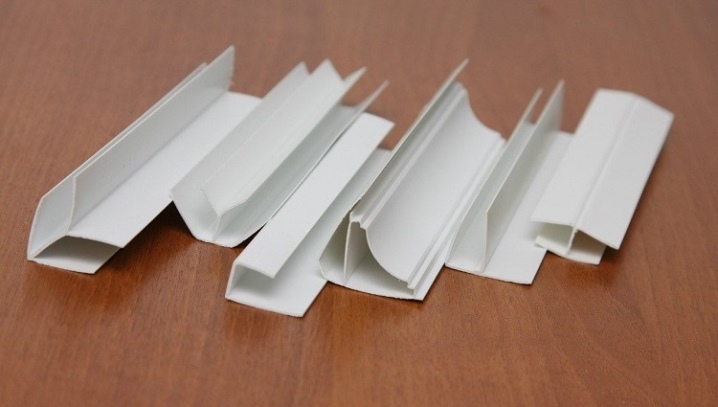

PVC is produced hard and soft, a hard look is used for construction. Products of all types are elastic, the material does not crumble or crack at the cuts, since there is practically no chalk in the composition. The service life is from 10 to 20 years, they are not afraid of sunlight and do not turn yellow. PVC planks are cheaper, good for decoration and cladding, and can be removed and reinstalled.

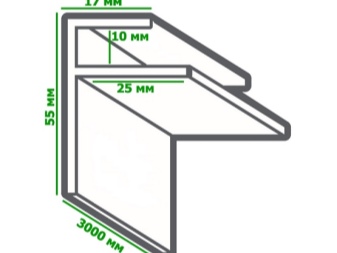

Ceiling skirting boards are selected from the same material during renovation. Colored types of skirting boards are produced - white, brown, black. Therefore, it is possible to accurately select the desired color. The length of one unit is 300 mm. If it is not enough to decorate the perimeter, the parts are fastened until the desired size is obtained.

Metal

Metal slats are produced from steel and tin with galvanized and aluminum. Galvanized products are not subject to corrosion and are not afraid of moisture, their service life is long. A flexible frame made of aluminum or steel strips allows you to take into account all the nuances in the finish, as well as reduce the load on the walls and ceiling.

The use of such structures allows you to reduce the cost without losing quality.

Species overview

Profiles differ in cross-sectional shape and other characteristics and are marked by manufacturers. Each variety is used for stable performance in construction and decoration. To fix the slopes along the opening to the wall, special latches are used.

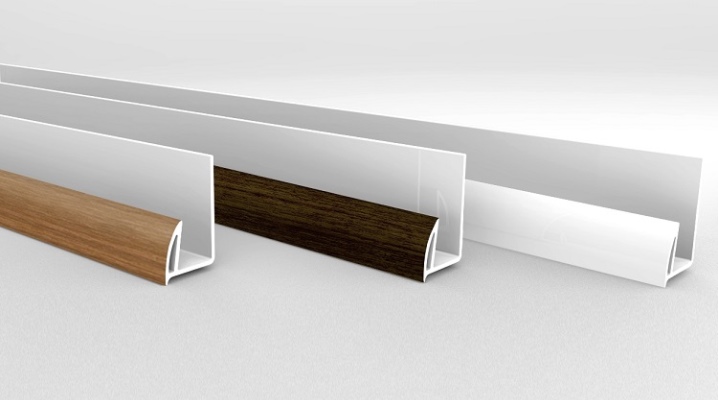

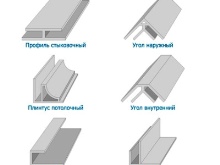

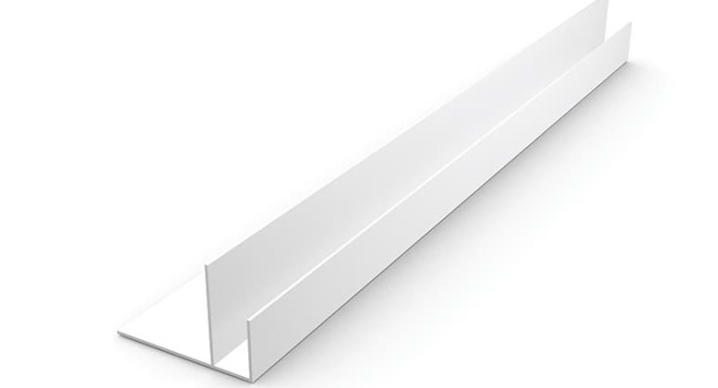

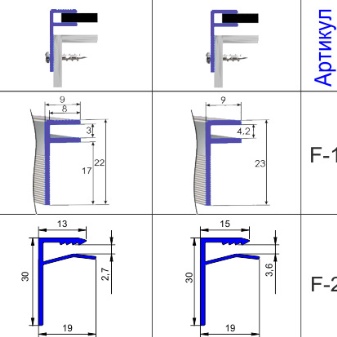

These types of plastic profiles are made.

- L-shaped. Fastened at right angles to the surface of the window. Includes three shelves in section, the large one is applied tightly to the wall, and the smaller ones - to the window frame and the butt joint, closing it.With this overlay, sufficient joint masking is achieved when installing standard 10 mm wide slopes.

- U-shaped. Similar in design to the previous form. Consists of two wide and one narrow shelves. Due to more solid parameters, the initial profile is used to mask irregularities and significant gaps when joining the panel to the base.

- F-shape. A frequently used type, it also consists of three elements - a long strip and two shorter ones adjacent to it. The profile is used for cladding when installing windows and doors. The rounding on the plank makes it possible to attach it to complex-shaped walls. At the final stage of installation, using such a profile, the plane is leveled, the ends are formed, and decorative finishing is performed. The window and the wall acquire a complete, aesthetic appearance. The second narrow shelf allows you to do without putty and glue, completely covering the joint of the strip with the cladding. The F-profile allows you to mount slopes both from polyvinyl chloride and from composite compositions with wood, laminate and plasterboard sheets.

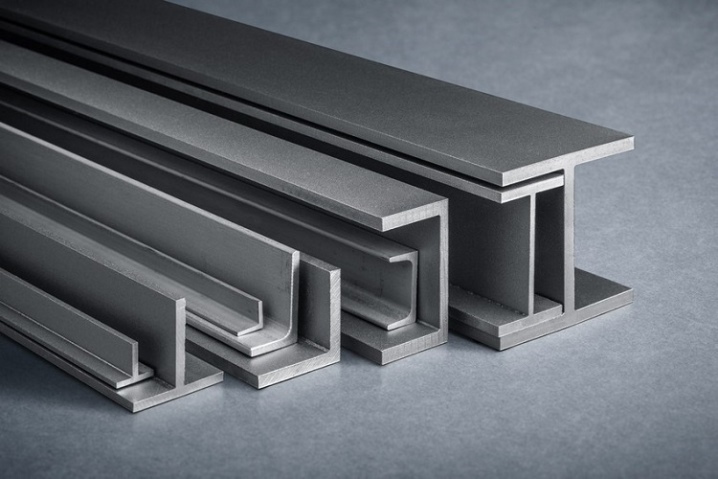

- I-form. The cross section outwardly resembles this large letter of the Latin alphabet. An elongated shelf is placed in the center, and a smaller one on the sides. The plank is mounted on the wall in any convenient position, the special shape of the product allows you to choose the desired option.

- H-shaped or connecting. Represents two identical strips with a jumper between them. The panels are connected with flexible samples, the joints at the ends and the joints between the wallpaper and panels are covered.

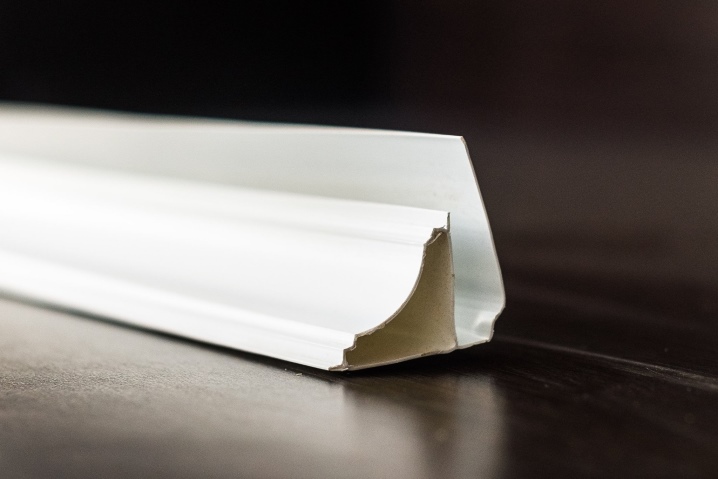

- Ceiling or fillet skirting boards.

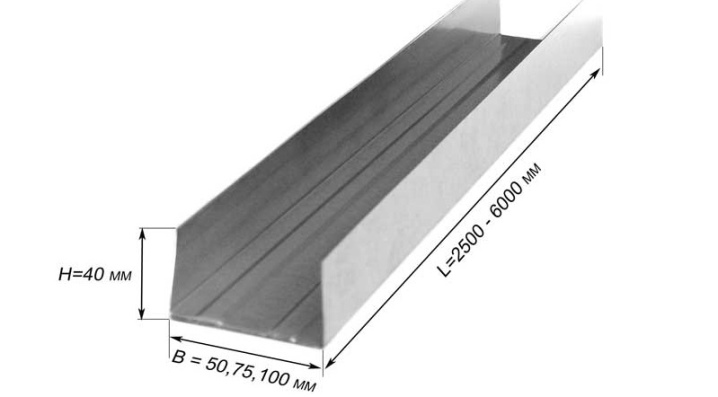

Metal profiles are divided into two types: flat and ceiling. Plane are produced by manufacturers for fixing and strengthening the structure. They are intended for various surfaces and are so.

- For walls. Products are used as the main ones in the course of finishing work and redevelopment. With their help, partitions are erected. Marking letters UW. For ease of installation, the rails are provided with holes. Overall dimensions - 50x40 with a length of 300 mm.

- Rack. They are used at all levels of complexity in construction. The slats act as racks that distribute the load. Allows to form artificial walls and partitions. Also necessary for wall lathing, provide sound insulation by gluing a special tape. They have rounded edges and are marked with letters CW. The length of the product can be up to 6 m. At the base, the plank reaches a maximum width of 100 mm.

The profile is installed together with the guide at a right angle to it.

- With enhanced properties. Wear-resistant and corrosion-resistant, the rolled profile is inserted into doorways and partitions.

Ceiling strips are available for assembly work and surface strengthening of elements. The profile of the CD brand is rigid, with special grooves. The metal frame used as a basic fastener is marked with UD. The high reliability of the ceiling structure is ensured by corrugation and drilling of holes in the starting rails to fix them on the ceiling. The flexible frame is easy to bend, adapting ideally to any curvature of the ceiling surface. Rack materials made of metal for creating arched openings are flexible, there are concave and convex types.

Convex specimens are 600 cm long and have an arc radius of 100 cm. The bending radius of the concave frame is 50 cm with a standard length of 300 cm. Corner profiles are fixed at the ends, which are subject to plastering, and also protect the corners of the structure; corners are made of galvanized steel. The holes in the corner strips are filled with mortar. This increases the reliability of the fastening at the points of contact with the wall.

Beacon profile elements are designed to obtain an even and neat surface. Supports determine the thickness of the plaster layer on the wall.

Dimensions (edit)

When choosing a configuration, the wizard needs to consider several important points. Depending on the thickness of the sheet, profiles are purchased that fit it in size. A standard sheet of cardboard for finishing works has a thickness of 12-12.5 mm. The maximum density of the material can be up to 90. The thicker the sheets, the larger the profiles are needed for fasteners. If the structure is bulky and heavy, complex in design, additional slats in the frame are required. This increases the stability and reliability of the installation.

In the course of using complex structures, the pressure on individual parts increases, therefore it is customary to calculate the maximum load on the frame. Massive objects can be placed on the ceiling and walls, which significantly increases the load. Assembly is easier if holes are made in the elements. The rigidity of the frame is increased by the corrugation of the coating.

Main technical characteristics of profiles.

- Length - from 2.7 to 4.5-6 m.

- Base width - minimum 5, average 7.5 and maximum 10 cm.

- Sectional shape, section dimensions - the standard is 27x28 mm.

- The mass of one plank is on average from 600 to 900 g.

Components

To cut aluminum starting profiles, the craftsman practically does not need to apply force, since the standard slats are quite thin, about half a millimeter thick. The mechanical method of connecting the frame, without screws and other components, is considered reliable by builders. But pulling the panels apart in the future, if necessary, will be a daunting task. The one-piece support system provides stability to the finish and is attached with accessories. Are used:

- dowels;

- screws;

- self-tapping screws;

- hanging parts;

- connecting and extending parts.

Dowels and self-tapping screws are designed for fixing to a plane, connecting guides and racks to each other. The frame of the wall and ceiling is fastened with suspensions, straight and anchor, leveling the structure in height. Docking of parts on the ceiling and walls, regardless of their location in relation to each other, is performed using connectors and extensions. Crab cross-shaped fasteners are often used for joining the slats on the ceiling.

Installation

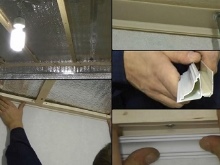

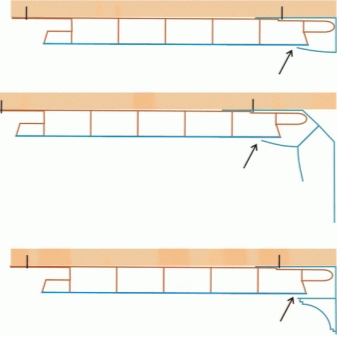

It is recommended to fasten the profiles to the plastic window according to the proven scheme. It includes several stages.

- Preparation. It consists in eliminating the gap that occurs between the panel and the window frame. The gap is sealed with special polyurethane foam. It is advisable to use not regular, but professional foam. The tube has a mount designed to be mounted on a gun. This allows you to close the gap thoroughly and in small portions, from the bottom to the top of the window. The remains of the hardened foam are removed with a knife. Old putty and primer do not need to be cleaned off, this is another advantage of using starter profiles.

- Beginning of work. Using a tape measure, measure the dimensions of the frame, then measure and cut the lengths of the plank to the same length. The ends are beveled at a 450 angle so that the connection is strong. First, the upper part above the window is filled, then the strips are placed on the sides of the opening, at the end the bottom of the window is closed. A neat, even edge is obtained by drawing a line along the frame along which the strips are installed.

- Fasteners. To secure the strips, you will need self-tapping screws, liquid nails and a drill. Self-tapping screws are screwed along the edge of the window at a distance of 20-25 cm. Liquid nails are applied in narrow waves along a piece of PVC, after which they are strongly pressed and held. If glue is visible, remove it with a dry cloth, as the dried material cannot be separated from the frame. Not all experts advise adding an adhesive composition. In damp rooms, due to temperature extremes, the chemical can flake off. It is also undesirable to stick the F-profile on the ends of panels or drywall sheets. PVC products hold perfectly, are designed for easy and quick installation and replacement when renovating a room.

- Lathing. This is a frame for a plastic panel. It is made from wooden blocks or metal slats.The wood is dried to prevent it from twisting and breaking. Antiseptic treatment protects from moisture during operation. The bars are fastened to the edge of the opening with dowels at a distance of 35-40 cm.

- Connection with cladding panels. Having measured the opening in length and depth, the plastic panel is cut to size. The panel is inserted at one end into the groove in the starting profile. The second edge is attached to the lathing using assembly glue. A strong connection is provided by self-tapping screws screwed at an angle of 450 at the ends. The platband will cover their tops. Then the side slopes are installed, last but not least, the decor. The connection with the profile ensures tightness, eliminates blowing, protects the window from freezing. The profile reinforces a wide window on the veranda or terrace of the house.

Ideal for installing a unit consisting of a window and a balcony door.

The comment was sent successfully.