Water supply valve for a washing machine: purpose and principle of operation

The water supply valve in the washing machine is no less important than the driven drum. If it does not work, then the washing machine will either not collect the required amount of water, or, conversely, will not restrain its flow. In the second case, there is a risk of flooding the neighbors living below you in a multi-storey building.

Characteristic

The water supply valve for the washing machine, also called filling, inlet or electromagnetic, has one important characteristic - the reliability of shutting off the water when it is not required to enter the tank. It should not leak, let water pass when it is turned off.

Manufacturers pay special attention to its proper operation, since not every housewife will turn off the valve for a while until the machine washes the laundry.

Location

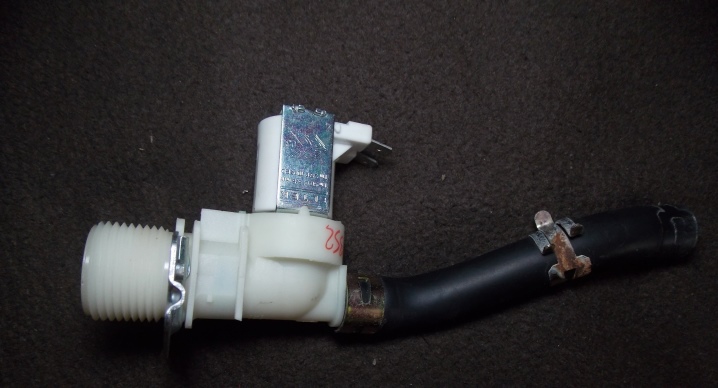

This shut-off element is located near the branch pipe connected to the water supply hose, through which water is taken from the source. Being one-piece, the valve is integral with this outer tube. Top-loading washing machines have a valve located at the bottom of the rear wall.

Principle of operation

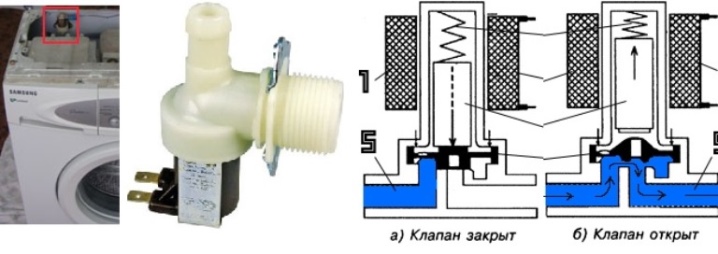

Water supply valves are based on electromagnets - coils of enamel wire, put on the core. The valve mechanism is wound onto this core.

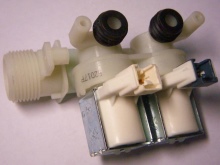

- Single coil valves the pressure is supplied to one compartment communicating with the space of the drum. Washing powder is poured into this compartment.

- With two coils - in two compartments (in the second, the anti-scale agent is poured on the boiler in the drum compartment).

- With three - in all three (the most modern version).

- An option is possible when two coils can control the water supply to the third compartment - they must be powered at the same time.

The supply of current is controlled by switching relays controlled by an electronic control unit (ECU), in which, in turn, the firmware ("firmware") of the washing machine runs. As soon as current flows to the coil, it magnetizes the core, which attracts the armature with a plug that restrains the water pressure.

In the closed state, the electrical circuit opens the valve, water enters the washing tank. As soon as the water level sensor fixes the maximum permissible level, the supply voltage is removed from the electromagnet, as a result of which the spring-return valve mechanism closes its plug again. The valve is closed most of the time.

Types and causes of malfunctions

The filler valve malfunctions are as follows.

- Clogged filter mesh. The mesh performs the function of preliminary filtration of water from small mechanical impurities and large grains of sand that can be brought in with the flow from the pipe during the flooding. Inspection of the mesh will reveal a possible blockage that has led to too slow collection of water into the tank. The mesh is cleaned from dirt with a stream of running water.

- Coil failure. Each of the coils can burn out over time. If it overheats due to too low resistance or a thin wire cross-section for the current supplied to it, then the enamel coating peels off, inter-turn short circuits appear. In a short-circuited loop, a large current is released, which leads to overheating of the coil and its destruction.The coil resistance is 2-4 kOhm, which can be checked with a multimeter (but only after disconnecting the coils from the current source - so as not to damage the meter). If it is zero or infinite, then the coil is changed. If you have a wire and the appropriate skills, you can rewind the coil yourself. The coil replacement process will speed up if you have another same (or similar, compatible) defective valve with intact coils.

- Broken or worn out flaps, acting as valves would also have to be replaced if the valve itself could be easily disassembled.

- Defective spring determined by the permanently open valve. Its breakdown will lead to the fact that the valve plug does not close when the current on the coil is cut off, water will flow uncontrollably and flood the room where the washing machine is located. The valve (the whole mechanism) is changed entirely.

Repair and replacement

To fix the water supply system, you need to disassemble the washing machine. Only defective coils can be replaced in the valve. The spring-loaded damper, water channels and diaphragms of the mechanism cannot be replaced in case of breakage. To replace the entire valve, do the following.

- Shut off the water supply (there must be a pipe with an emergency shut-off valve on the machine).

- Disconnect the machine from the power supply and remove the back panel.

- Disconnect the hoses and wires from the filler valve.

- Remove the hardware holding the valve in place.

- Having unscrewed the bolts, self-tapping screws and unfastened the latches, turn the valve and remove it.

- Replace the faulty valve with a new one.

- Follow all the above steps in reverse order to recover the system.

Try starting the machine with an unwanted piece of cloth or rag in it, but do not add powder or descaler. Turn on the fastest time mode, observe the water intake and valve actuation.

It must work accurately, not letting excess water into the drum tank... After making sure that the water filling and drainage are working properly, turn on the water drain and complete the cycle. Replace the washing machine.

Conclusion

Replacing the valve mechanism that supplies water to the washing machine tank with your own hands is a feasible task for every ownerfamiliar with electricity and electrical safety when performing work, having at least a general idea of how household appliances work. Otherwise, the machine must be sent to the nearest service center.

How to clean the water supply valve in the washing machine, see below.

The comment was sent successfully.