How to connect the motor to the washing machine?

After completing their due date, automatic washing machines fail and must be replaced, but do not rush to take out old equipment in the trash. In many washing machines, an electric motor remains in good condition, which, if desired and at least minimal skills in working with electrical engineering, can be used not only for various household needs, but also for performing small industrial work. The electric motor from the washing machine has the ability to connect to a 220 W power grid, and its speed develops to very impressive indicators - 10-11,000 revolutions per minute.

The electric motor can be connected to any equipment, for example, make a knife sharpener, a mixer for mixing concrete solution, build a small home lathe or grinder, a grinder, make a powerful fan or heat gun to heat a garage or summer cottage, create a grinder for materials different factions and so on. Craftsmen even make an electric generator from an old motor. The main thing is your desire and skill.

Designs and applications can be any, but a used electric motor from a washing machine will help to set them in motion, which will greatly facilitate your manual labor and become a good economic aid.

Description of different types of electric motors

A modern automatic washing machine, as a rule, has a three-phase electric motor, but the old Soviet counterparts could have a two-speed mode of operation, although they are now very rare. Any electric motor is an apparatus powered by electricity, and it is intended to set in motion various structural elements.

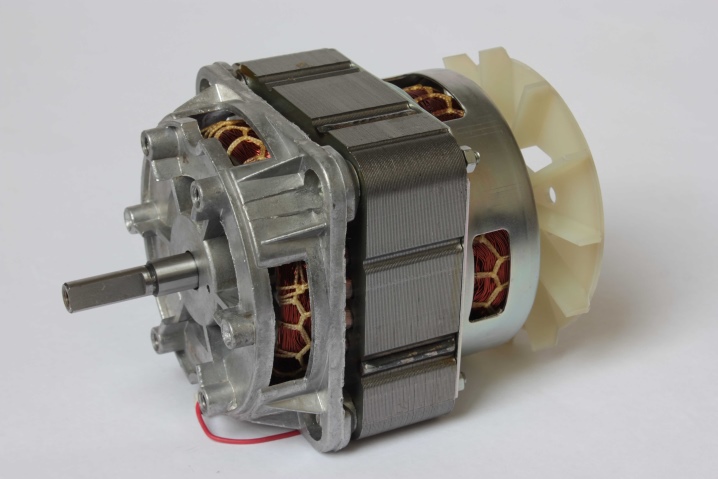

Disassembling the washing machine, you can see in it an electric motor with a tachogenerator, which regulates the number of revolutions made by a rotating shaft, and depending on the type, the electric motor can be brushed or designed without the use of brushes. Different manufacturers of automatic washing machines use certain types of electric motors for different models, which are divided into 3 options.

Asynchronous

Most often, asynchronous electric motors are three-phase, but among them, old models of washing machines sometimes come across two-phase options. Asynchronous electric motors are used in 90% of household appliances, since their design is reliable and inexpensive in terms of cost. The basic principle of operation of such an electric motor consists in the combined action of the stator magnetic field and the fluxes that are generated by this field in the rotor. The rotation of the electric motor occurs when the frequency difference arising in the process of rotation of magnetic fields.

Asynchronous motors are reliable and durable, their maintenance consists of regular lubrication of the internal bearing mechanism. However, such an electric motor is heavy and bulky, which is not always convenient during its use.

The efficiency of asynchronous electric motors is not the greatest, therefore they are used for household models of medium-power washing machines.

Collector

This type of electric motors has become a modern modification, which has come to replace large asynchronous models with low efficiency. In contrast to them, the collector electric motor has the ability to operate from both direct and alternating voltage of electric current. The electric motor consists of a fixed stator and a movable rotor. The stator generates energy, and the rotor transfers it to the rotating shaft, which is an integral part of it. The shaft has a collector, thanks to which electricity is supplied to the rotor winding.

Such an electric motor is capable of rotating in any desired direction, that is, to the right or to the left, it is only necessary to change its polarity when connecting the brushes on the stator winding. The collector type of an electric motor is characterized not only by a high speed of its rotation, but also by the possibility of a smooth change in the speed mode, which is regulated by changing the voltage. The collector electric motor has compact dimensions, in addition, it is characterized by a large starting torque.

This electric motor requires frequent replacement of brushes and cleaning of the collector, which is carried out as a result of regular preventive inspections of this type of unit. The brush assembly is considered to be the weakest point in such electric motors. And although the period of operation of the brushes is from 8 to 10 years, all this time during operation the brushes are grinded, due to which fine coal dust settles on all other parts of the electric motor.

Inverter

Today, the most modern type of electric motor, with a compact size and a high level of efficiency at high power, is the inverter type. It, like other electric motors, has a stator and a rotor, but the number of connections between them is minimal.... Since there are no elements inside the electric motor that wear out quickly during operation, this allows the unit to work without interruptions for quite a long time, without creating noise and vibrations. Inverter electric motors are in expensive models of washing machines, since the cost of such an electric motor is much higher than its counterparts.

Analyzing the properties of all 3 types of electric motors, it can be concluded that the asynchronous option is the simplest in design, but it has a low level of efficiency. The collector type of the electric motor is good in that it makes it possible to adjust the rotation speed.

And an inverter-type electric motor is able to work without the use of brushes and other parts in its design, which are used in other types of electric motors.

Connection diagram

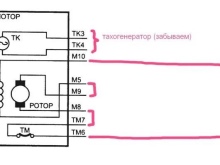

Connection to the power supply network for new generation washing machines is made using a special block with terminals. If you have a collector engine, then this block will contain:

- 2 connections from brushes;

- 2 (and sometimes 3) electrical contacts coming from the stator winding;

- 2 wires connected to the tachometer sensor.

Inside the engine, the connections are located in the dispensing unit.

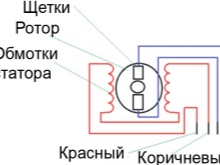

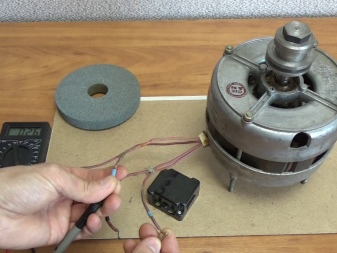

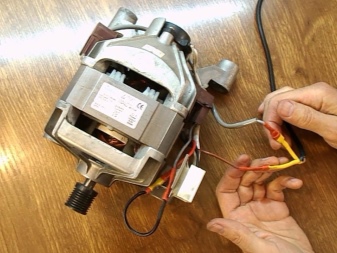

Before connecting an electric motor from an old washing machine, it is necessary not only to determine its type, but also to find all the available electric wires in the dispensing unit. You should find there 2 white wires that go from the tachogenerator, then find the red and brown wires that go to the stator and rotor, and also find the green and gray wires - they are attached to the graphite brushes. When performing work, pay attention to the fact that the electric motor does not need to start through a capacitor, and the connection does not require a starting winding either.

Next, you need to move the wires that are attached to the tachogenerator, since they are not required to connect the electric motor. The color of the braid of the wires for washing machines from different manufacturers may differ, and in order to determine them correctly, you need to be guided by their resistance. Those wires that are attached to the tachometer will show a resistance of 50-70 ohms. The remaining wires that will participate in connecting the electric motor must be ringed with a multimeter - this will help them find their pair.

Before turning on the electric motor, you will need to fix it on a stable surface. It should be remembered that as soon as you try to connect an electric motor to a 220 W power grid, its shaft will immediately begin its high-speed rotation. For this reason, care must be taken when carrying out commissioning work so as not to injure hands.

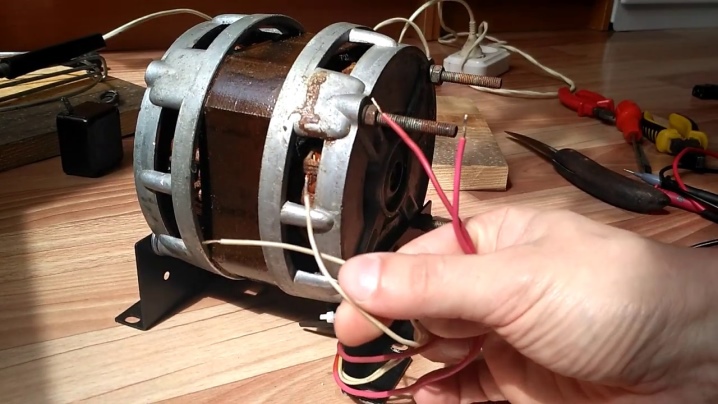

The old Soviet washing machine, like most modern models, has an electric motor with four wires, that is, these are 4 leads coming from the motor. But you can also meet with electric motors, which will have 5, 6 or even 7 pins, although to turn on the electric motor you only need to find wires that are directly connected to the stator and rotor.

Excess wires can be contacts of the control board, with which the operation of the washing machine is adjusted and the washing programs are selected.

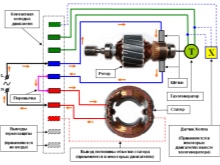

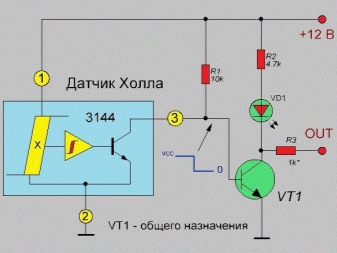

You can see the connection made in the shown wiring diagram. Using the electrical circuit, you need to detach the stator winding and rotor brushes, for which you need to find the corresponding contacts on the electric motor and make a jumper between them, called "pinout", which you should insulate in the future.

On the wiring diagram, the jumper is shown with pink arrows. The remaining 2 contacts, which remain from one more brush and the rotor winding, are connected to the mains. Further, the device must be equipped with an on-off lever, and in order to adjust the direction of the shaft rotation side of the electric motor, you need to throw such a jumper to the other 2 contacts.

Old technique

Old-style washing machines most often have an asynchronous type of electric motor, which has 2 windings - working and starting. The difference between them is that in the starting winding, the data of resistance indicators during measurements will be higher than that of the working one. If, when disassembling an electric motor, you see contacts from both of these windings, and they are in good condition, then it will be easy to connect such an electric motor. This can be done using a capacitor designed for a voltage value equal to 450 to 600 V. The capacitance of the capacitor must be at least 8 μF.

When connecting an electric motor, pairs of contacts are found from the working and starting windings, and then they are connected to the capacitor. If, during a test run, the electric motor rotates in the wrong direction, which you need, you need to swap the connection contacts at the starting winding.

Modern automatic machine

Most automatic washing machines are equipped with asynchronous electric motors, so we will consider its connection as an example.

Three-phase electric motors of an asynchronous type are the most common units that can operate even at a voltage of up to 380 V. But in order to connect them to a single-phase 220 V power supply, you will need to connect a capacitor - it will not only keep the voltage drops in the network, but also reduce the power of the electric motor, which will ensure you safety when using it.

To connect, you need an electrical wire with a plug at the end, a capacitor is connected to it. Then pinout is made - for this, a jumper wire is attached to the other side of the capacitor. Next, you need to ring the motor winding with a multimeter to detect contacts with a minimum resistance.Then wires are inserted that will be connected to the power supply, and a capacitor is connected to them.

After turning on the electric motor, if the starting capacitor is fixed correctly, you will see the rotation of the shaft.

If it is required to preserve the operability of the electric motor, but at the same time to regulate the number of its revolutions, then a tachogenerator is connected to the engine - every model of washing machines has this sensor. "Hall sensor" - as it is also called, not only controls the number of revolutions of the motor shaft using a special microcircuit. With its help, the washing machine evaluates the weight of the laundry. When the laundry is saturated with water, weight sensing allows the sensor to select the desired speed that is required to spin the drum.

When installed on an electric motor, the tachogenerator has 3 outputs - 2 outputs are needed to connect the power supply, and another 1 output takes readings of pulses.

It is important not to mix up these contacts during installation in order to get the desired effect from the sensor.

Helpful hints

Sometimes it is not possible to start an electric motor from an old automatic washing machine, and the reasons for this are both mechanical and electrical.

The reasons for the difficulties in starting an electric motor can manifest themselves as follows.

- When turned on, the electric motor heats up, but the shaft does not rotate. If you try to rotate the shaft by hand, you can hear the grinding of metal parts. This sound indicates that the electric motor has a damaged bearing mechanism and needs to be removed and replaced.

- Sometimes the rotation of the shaft of an electric motor can be difficult if any foreign objects have accumulated in the gap between the stator and the rotor, which must be removed and tried to start again.

- Ringing out the entire electrical circuit with a multimeter will help to identify the presence of an open. For electric motors of the collector type, the starting problem may lie in the worn out brushes, as a result of which they cannot tightly adjoin the collector and no energy is generated.

Sometimes, when starting an electric motor from modern models of washing machines, they try to determine the starting winding, but new generations of electric motors do not have it, and such a motor is started without the use of a capacitor.

You can find out below about a simple way to connect the washing machine motor without appliances.

The comment was sent successfully.