Hansa washing machine error codes: description, causes, elimination

Hansa washing machines are among the most high-tech household appliances. They all differ in size, color, number of functions. Many modern models can not only wash different types of fabrics in different ways, but also self-cleaning and self-diagnostics.

Decoding errors

Thanks to the display, the user can see error codes that now and then appear in different departments. Using the error code, you can quickly find out why the washing machine is not working and, if it is possible to eliminate this error at home, quickly fix the breakdown, and continue to use the equipment.

The multifunctional washing machine has many error codes, just like functions. One of the most common simple mistakes is E01. This error is due to a poorly closed hatch. But the user of the washing machine does not need to give up and buy new washing equipment.

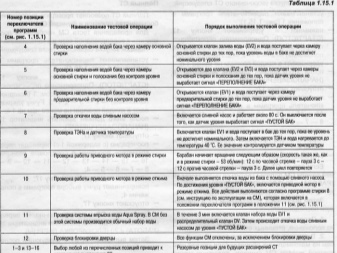

The following are the main error codes for Hansa washing appliances:

- E02 - no blocking of the hatch;

- E03 - (RS series) slow emptying of the tank (more than one and a half minutes);

- 2.2. limiting the spin cycle to 400 rpm;

- E03 - (RA series) the water filling sensor installed in the tank does not give a signal after 3 minutes from the beginning of water entering the tank;

- E05 - during operation, the sensor installed in the tank sends a signal about the tank overflow to control the level;

- 4.2. open or short circuit of the temperature sensor;

- 4.3. slow and gradual heating of water in the tank, more precisely, less than 4 degrees in 10 minutes;

- 4.4. due to slow heating at the set time, water heating cannot reach the norm;

- E06 - failure to send a signal from the level sensor about an empty tank after 10 minutes after the start of water draining;

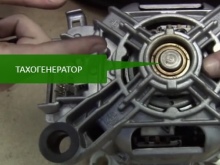

- E07 - the tachogenerator does not give a signal about the correct operation of the drive motor in the set wash mode, the drum either does not rotate at all, or does it at insufficient speed;

- E10 - when the power supply decreases or increases, the discrepancy with the recommended power supply parameters;

- E21 - lack of a signal from the technical sensor, engine problem;

- E22 - independent operation of the drive motor without appropriate commands;

- E08 - (PA) in the spinning mode from the side of the tachogenerator, no signal is sent to the electronic controller;

- E11 - (PA) short circuit of the TR8 triac of the drive motor;

- E12 - (PA) error when water leaks into the lower part (sump), the AS1 sensor is triggered;

- E14 - (PA) faulty operation of the electronic controller due to unstable power supply in the network;

- E15 - (PA) complete malfunction of the electronic controller;

- E32 - (PC) open circuit in the temperature sensor wire.

Possible causes and their elimination in different departments of the machine

Water supply and discharge

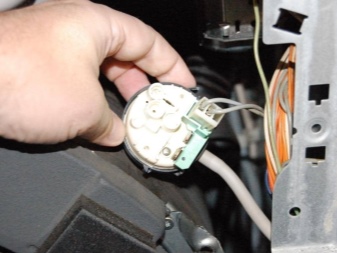

E03 - (RA series) the cause of this error is the lack of water in the pipe, insufficient water pressure, damage to the CV1 and CV2 solenoid valves, broken level switch, incorrect operation of the ASJ control valve of the Aqua Spray system.

Solution: updating the filler valve, replacing the pressure switch, repairing the control board, if there are control valves, they need to be replaced.

E03 - (RS series) clogged drain pump filter, clogged drain hose. The machine cannot start draining the water.

Solution: the user of the washing machine must remove the cover from the pump and pull out the clogged filter, thoroughly clean and close the cover.Complete rinsing of the drain hose.

E06 - incorrect operation of the drain pump, debris in the drain hose, faulty operation of the level sensor or wire connections.

Solution: replacement of the drain pump, temporary repairs to get out of the emergency position, complete cleaning of the drain hose, if possible, visually inspect and feel with your hands from beginning to end, updating the pressure switch.

E12 - a quickly rectifiable error occurs due to water leakage into the sump, damage to contacts and wires, or incorrect operation of the float sensor (AS1).

Solution: this error can and should be eliminated as quickly as possible. To do this, the user needs to do basic things, no need to call the wizard. To begin with, visually inspect the washing machine and prevent water leakage, then restore the wiring and their contacts.

If after these actions the error is not eliminated, then the user needs to change the float sensor.

Heat

E05 - incorrect operation of electrovalves, oxide of wire contacts, unstable supply of water pressure, incorrect operation of the electronic controller.

Solution: if the valves are malfunctioning, you need to update the filler valve, mount / install a new pressure switch, pull out the board and take it to the master to repair the control board.

Visual check of wires or replacement of a faulty sensor with a new one or with a used one (temporarily as a way out), in case of a malfunction after applying the two previous steps of action, the user should try to replace the electrical unit.

Checking the wired contacts, if the user detects a malfunction on the wires, urgently replace the wires, replace the heating element, or you need to contact the power supply to correct the reception of electricity.

Drum

E07 - incorrect operation of the drive motor M1, the tachogenerator is inoperative, the problem is in the wiring, the electronic controller is damaged.

Solution: for reliable and long-term operation of the motor, it is best to replace the drive motor with a new one, or for temporary work take it to a specialist to repair the motor, update the tachogenerator, check and correct the wiring, repair or completely replace the control module.

E21 - the motor is inoperative, bad wires, due to which there is no connection between the controller board and the board.

Solution: initially checking the motor, you need to carry out the appropriate diagnostics, if possible, repair the motor. If the motor cannot be repaired, then install a new one instead of the old one. As well as checking the wires and their contacts. If oxide is found, a complete cleaning or replacement of the wires is required.

E08 - There may be several reasons. Incorrect operation of the drive motor, wiring contacts, an inoperative tachogenerator or an electronic controller in an inoperative state may be damaged.

Solution: repair or replacement of the drive motor, replacement of the tachogenerator with a working one, the user of the technician needs to completely perform a visual check of the wires and their contacts. As far as possible, cleaning the contacts or replacing the wires, if these solutions do not help in eliminating the detected error, then you need to repair or replace the control module of the washing machine.

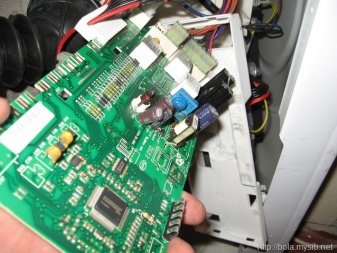

Electronics

E02 - occurs in the following cases: if the electronic controller is out of order, when the electronic door interlock device is inoperative, when the voltage is low, as well as when the wire is damaged.

Solution: replacement or repair of the controlled unit. This approach includes a thorough visual inspection, installation of a new UBL, restoration / cleaning / replacement of wiring.

E10 - when you turn on the washing machine or during operation, decrease or increase in the power supply.

Solution: Thoroughly check the voltage at the outlet. At low voltages, it is recommended that the user of the technician install a stabilizer to obtain a continuously stable voltage in the outlets.With the help of the stabilizer, the owner of the technique will also protect his other devices related to electricity.

E22 - faulty operation of the triac of the drive motor.

Solution: visually inspect the electronic module. Check the module with technical equipment, if possible, fix / repair this module. After checking the module by the user or a specialist, if required, it is imperative to replace this module.

E11 - in this case there can be only two errors. The first is a bad or completely inoperative state of the TR8 triac. The second is the M1 motor in an inoperative state.

Solution: To fix the first problem above, the control board should be repaired if possible. If the board cannot be repaired, then you need to completely replace it. To eliminate the second reason, there is only one option - replacing the motor.

Without repairing a faulty motor, the user will not change anything. The M1 motor will continue to break down and cause damage to other parts. Because of this, it is recommended to install a new motor immediately.

E14 - this error can be detected when the process is interrupted during washing.

Solution: you need to check the voltage in the outlet, if the voltage is normal, you need to turn it on again and set the washing mode. If after these steps there are no changes, then the user of the washing machine must replace the old electronic controller with a new one.

E15 - the error is detected when turning on the washing equipment or after selecting the settings for the washing mode, after 3 seconds after giving the command "Start". Or with a faulty electronic controller.

Solution: this error, unfortunately for the user, cannot be eliminated at home. There are two ways out: take the electronic controller to a repairman of household appliances for repair, if the controller cannot be repaired, you need to buy a new control module and install it.

E32 - the failure can be caused by two factors. This is a burned-out sensor or a wiring problem.

Solution: the user must check the electronics for serviceability, if there is damage in the wiring, then replace the wire. If the wire is normal, the NTC sensor must be replaced.

How to reset?

Usually, a simple shutdown and restart of the machine is enough to reset the problem. But if this method does not work, and it often does not work with errors E01 and E02, you need to remove the plug of the washing machine from the outlet for 30-40 seconds, after which the door will automatically unlock.

If you have a malfunction of the main board, then it is possible to reset its error only after replacing the part.

Typically, many of these problems are found in older household appliances. Used parts are more prone to breakage and malfunctions. However, newer models are not immune to any of these problems.

The main thing is to understand what kind of malfunction the machine is signaling and change the corresponding parts in time.

How to repair the electronic module of the Hansa washing machine, see below.

The comment was sent successfully.