Brushes for the Bosch washing machine: purpose and replacement features

Brushes are a necessary removable element of the power supply system of any electric motor. Their failure is an unpleasant, but inevitable result of the operation of the unit. If the machine is used intensively every day, the replacement of these small parts will be required after 3.5 years, and if the washing is organized less frequently, the onset of this inevitable result will be postponed by another 5 years. One wash per week, which is actually unlikely, will allow the machine to work without changing the brushes decades.

Appointment

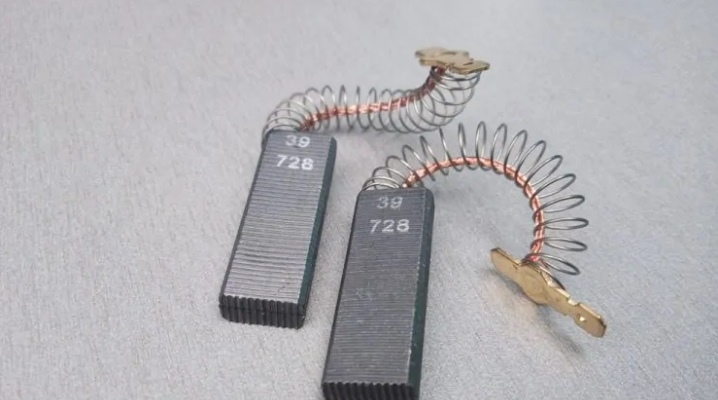

Graphite brushes are an indispensable element of an electric motor. Their main function is to transmit the electric current received through the terminals to the rotor of the electric motor. Due to this, it rotates. Thus, electric brushes perform work whenever the washing machine is started. A special device that includes a spring presses them against the rotor, rotates it and leads to gradual wear of the surface of brushes made of softer material.

For most modern washing machines, so-called carbon brushes. More powerful electric motors are equipped with more durable components that have a longer service life. Bosch washing machine brushes are available from specialist dealers or service centers.

The company uses several design options for its products, therefore, when replacing it, it is important to try to purchase a set suitable for a particular washing machine model.

What to replace?

Sometimes the original brushes may not be on sale, for example, for models that have been discontinued. As a rule, service centers carry out the order of the required brushes, but they have to wait for some time. Some owners of washing machines decide to replace the original products with something else. The service center can suggest a model that is interchangeable or compatible with the original. Some Bosch washing machines are compatible with brushes made by Indesit or other European manufacturers.

It is important that the dimensions of the parts match the original.

Sometimes it is possible to purchase brushes without springs, in which case the user may need to be able to solder the contact wire to the terminal from the old brush with a spring. Some craftsmen alter brushes from other electrical appliances, grinding them to the desired size. Such devices can work well for some time, however, the hardness of the material in this case does not always coincide with that for which the engine rotor was designed. The consequences of such repairs can be very sad; an expensive engine will have to be replaced. In any case, it should be remembered that the installation of a non-original part is a temporary matter, and it is still better to try to purchase the appropriate brush washing machine model with their prompt installation.

Causes and signs of wear

As already mentioned, the cause of wear on the brushes of an electric motor is a natural matter. Their failure is not a serious breakdown of the machine, it is the result of the normal operation of any electric motor, and it will be required in any case - either earlier or later. It is important to replace this replaceable element on time, then this process will take place with the least consequences and will not affect the usual family way of life. That is, you do not need to postpone a banal wash until better times. The signs of brush wear usually appear gradually.

- The appearance of an atypical knocking and cracking sound during the operation of the machine.

- Poor spinning of the laundry due to a drop in engine power.

- The appearance of a smell of burnt rubber or plastic during the operation of the washing machine (under certain conditions, you can notice arcing in the electric motor).

- Stops of the machine during operation, not associated with interruptions in the power supply.

- Failures of washing machine programs with highlighted on the display of faults or errors in the operation of the engine (fault code: E or F21).

It is important to identify the wear of the brushes as early as possible and replace them; this procedure cannot be postponed for a long time. Unlike many others, this problem will not go away on its own, and it can be costly to ignore.

Step-by-step instruction

Before proceeding with the replacement of electric brushes, it is necessary to provide the process with the appropriate tools, in the absence of which this simple operation will be impracticable. In order to change the brushes of the washing machine electric motor, you will need the following items.

- Slotted screwdriver with removable tips (flat and hexagonal tip required).

- It is better if the tool kit includes a stationary flat screwdriver of medium size.

- Socket wrench with the size corresponding to the heads of the bolts of the electric motor.

- Pliers.

- Headlamp.

- For especially advanced amateur craftsmen, a voltmeter may be useful.

The step-by-step process of replacing electric brushes can be represented as follows.

- Disconnect the machine from the power supply.

- Turn off the water supply and disconnect the inlet hose from the washing machine, as you will need free access to the back of the case.

- Drain the remaining water from the drum and drainage system by unscrewing the drain filter cap. This will make the machine lighter and protect against accidental water ingress on the motor terminals.

- Move the car so that there is enough space around it. You may need to move the unit from the bathroom to a larger room.

- Remove the top cover to access the back of the case. Remove the rear panel. For some models, it is necessary to unscrew the hatch fasteners on the rear panel (the rear panel itself may be non-removable) and remove the drive belt from the drum pulley.

- Carefully examine the engine, it can be located so that it does not need to be dismantled. However, for many Bosch models, replacing the brushes requires removing the electric motor, in which case you will have to turn off the power to the motor and unscrew the mounting bolts with a socket wrench. Slightly shaking the engine to remove it from the rails. Such washing machines must be turned on their side, and all manipulations must be performed from the side of the lower supports of the machine.

- Brushes can be of different designs. To remove them, disconnect the supply terminal using a flat screwdriver. Pulling out the contact plate, the brush spring is released, which throws it out.

- The new brush should be installed taking into account the abrasion angle of the old brush. As a rule, new brushes already have a slight bevel on the working side.

- Next, you need to place the spring of a new brush in the appropriate niche, this does not always work out right away.

- Press down the spring with the contact plate, on which to put the terminal.

Reassembly requires attention, all manipulations must be performed carefully, ensuring the reliability of all connections.

Illustrative instructions for replacing brushes are given below.

The comment was sent successfully.