Staples for construction staplers

Often, during construction work, there is a need for a strong and reliable connection of materials to each other. For this purpose, special construction staplers are often used. Such devices connect objects using special brackets. They can be of various types and shapes.

Peculiarities

The basic requirements for such brackets can be found in GOST 4028-63. Such consumables for staplers are most often produced in whole blocks, in which there are many pieces at the same time. This can significantly reduce the stress on the bonding device. In this case, the individual fasteners are fastened with a special tape.

These blocks must be inserted into a dedicated compartment on the device. When you press on the device, the staples will automatically be pushed out one by one.

It is worth remembering that the mechanism of each individual stapler is also designed for a certain size and shape of consumables, this must be taken into account when choosing. Such fasteners make it possible to make the process of fastening building and finishing materials the fastest and easiest.

Types by shape

Construction staples can be classified according to various reasons.

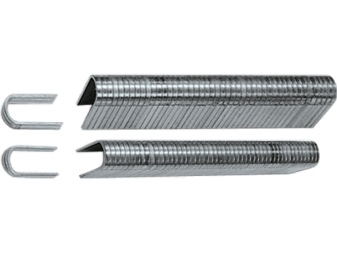

U

Such models are products with the legs pointing down. These types of brackets are rarely used during installation and finishing work, but they are necessary to perform certain activities carried out in the course of economic activity.

Mostly this arcuate variety is used if it is necessary to firmly fix wires and cables for different purposes and cross-sections.

NS

These patterns are versatile. They are quite often used during construction and finishing works. They can be made from a wide variety of materials. They can be used almost everywhere, except for fixing the wiring.

T

T-shaped varieties are the most rarely used in practice. They make it possible to make strong and durable connections that will not bear any load. In this case, everything is done in the most hidden way.

Dimensions (edit)

When selecting fasteners for a construction device, it is necessary to take into account their dimensions. To date, manufacturers produce models with a wide variety of standard sizes.

U-shaped and T-shaped versions can be produced in two versions.

-

28. Such samples are more often used to fix cable parts with a cross section of 4.5 mm, the thickness of the clip itself starts from 1.25 mm, and the height of the ends is 10-11 mm.

-

36. These products for devices have a thickness of 1.25 mm, while the height of the bent ends can vary within 6-10 mm. These devices are most often taken to work with wires with a diameter of 6 mm.

U-shaped devices also have their own specific dimensional values.

-

53. These specimens have a thickness of 0.7 mm, a length of 11.3 mm and a stem height of 4 to 14 mm.

-

55. This type of staple is most commonly used for electrical equipment. The legs are usually 12 mm high. The dimensions of the wire used are 0.83x1.08 mm.

-

140. These staples have an increased degree of rigidity, with a height of 6-14 mm, a length of 10.6 mm, and a thickness of 1.25 mm.

And also there are several separate types of such staples.

-

Type 300. Models in this group are small T-shaped fasteners.They have a head, the thickness of their metal rod is 1.2 mm. They are available in lengths of 10, 12 and 14 mm. Typically, they are used to fix different materials to plywood and other wood substrates.

-

Type 500. It is a finishing option, not equipped with hats. The length is also 12, 14 or 10 mm.

Remember that each type is labeled differently. You can often find models with the designation CM53-12b, which, among other things, indicates the type and size of the bracket.

The leg length is of paramount importance. After all, the strength of the future connection will depend on this parameter. The thicker the structure that needs to be fastened, the longer the leg should be. Moreover, in such cases, more powerful equipment will also be required. Otherwise, the consumables simply won't be hammered into the surface.

The thickness of such a spare part should be selected depending on the type of material being processed. For the most durable products, fasteners with a small thickness (within 0.75-0.8 mm) will be sufficient. If the material is thinner, then a fastener may well be suitable, the thickness of which varies from 1.25 to 1.65 mm.

Materials (edit)

Such attachments for joining materials can be made from various metals. Let's consider the most common options.

-

Stainless steel. Most often, stainless steel is used for the manufacture of such consumables. It is these models that have found the most widespread use in construction work. If they will be used for fixing solid structures, then preference should be given to hardened samples made of stainless steel. Such brackets have sufficient resistance to mechanical stress, they can provide the most reliable and durable connection. These types of fasteners are highly resistant to corrosion, so they can be used to fix structures that will later be placed outdoors. But it is worth remembering that such products are considered quite fragile, they can easily break under the influence of lateral loads.

- Cink Steel. This material has the highest resistance to rust, which is achieved due to the presence of a special top zinc coating. It is this that prevents the formation of corrosion on the metal under the influence of water and oxygen. This will not require additional processing of the material. Staples made of galvanized steel have a maximum service life, a high level of strength, and a relatively low cost. In addition, such consumables for staplers can be used in any climatic conditions, so they can be taken to connect structures that will be located in the open air.

-

Aluminum. This metal is also often used in the manufacture of staples for construction staplers. Aluminum models also have good resistance to the formation of a corrosion layer. In addition, they can be used in aggressive environments without deteriorating or losing their qualities. But such a metal is too soft, so it cannot be used for working with objects that are too hard. Most often, aluminum products are taken to fasten cardboard parts or when sheathing structures with soft fabric materials.

- Copper. Copper brackets also have excellent corrosion resistance. Compared to many other materials, copper has a significant cost, so it is not often used for the manufacture of such products. These fasteners can be used as decorative elements when covering furniture structures. Often, various colored coatings are applied to them.

Fasteners made from a steel base can be produced either hardened or unhardened. The hardened version will have a higher price, but during long-term operation the product will turn out to be much stronger and more durable, more reliable.

In addition to stainless steel and galvanized metal, it is also permissible to take a simple steel base. The disadvantage of such products is that during use they have the ability to oxidize and then rust, so such a connection will not be durable and strong enough.

Despite the metal from which the products can be made, there are products with simple standard legs and sharpened ends. Sharpened models will be much easier to go into almost any material, so the impact force can be less.

Some models of staples are made with nickel plating. This is a special coating method in which the product looks chrome-plated on the outside. They will not rust for a long time and will retain their neat appearance.

Copper plating is also sometimes used. This coating is protective and decorative. As a rule, it gives the products a beautiful pink or red hue. This application is able to protect the material from the appearance of a rusty layer.

How to choose?

Before buying a suitable version of such brackets, it is better to pay special attention to a number of important nuances. To begin with, it is worth deciding on which surfaces the work will be carried out. So, for furniture designs, it is worth taking staples with sharpened ends. They will easily go into the base. If you use a simple hand stapler to do this, then you will have to use much less physical effort.

If you need to install vapor barrier materials, then aluminum samples are suitable. To work with clapboard, stainless steel will be the best option. Aluminum for lining should not be used, since it does not have the required level of strength, and when the timber structures swell, the bracket may simply fall out.

And also before picking up consumables, think under what conditions the structures that are connected will be used in the future. If they will be located in rooms with a high humidity indicator, including saunas, baths, then preference should be given to models made of processed metal that are resistant to corrosion.

An important selection criterion is also the indicator of the load that will fall on the fastener. If a small load is assumed, then standard aluminum varieties may well be suitable. For fixing hard and hard materials, it is better to use stainless steel specimens.

Fasteners can be sold in sets of different quantities. Often in stores you can find blocks of 100, 200, 500, 1000, 5000 parts. In this case, the choice will depend on the type of installation and finishing work that will be carried out.

Sometimes, with constant work with such equipment, it eventually stops firing staples, fasteners can get stuck inside the device, and several staples can fly out at once.

In the event of malfunctions, the product often begins to bend the staples inside, as a result of which the connection may turn out to be weak. In order to avoid breakage of the tool and consumables, it is necessary to correctly select all parts according to the size and expected load, the type of materials to be joined.

Many experts advise against buying too cheap staples. As a rule, they do not undergo the required processing during the manufacturing process, they are made of lower quality metal, therefore, during operation, they begin to deform and collapse easily.

Most often, staples are bought immediately along with a new stapler.Remember that for each individual model of such a device, only certain types of fasteners will be able to fit. As a rule, the number of suitable staples is indicated on the packaging for the device itself.

The comment was sent successfully.