Wall masonry in one brick

Brick laying has been considered a responsible construction job for centuries. The 1 brick masonry method is available to non-professionals. In terms of speed, experienced bricklayers, of course, cannot be won, but your own accuracy is free. Here, as in other construction cases, the old rule "the master's work is afraid" is relevant.

Brick types

Brick by its quality greatly affects the properties of the structure. Classic ceramic red bricks are made at a temperature of 800-1000 degrees. Clinker differs from ceramic only in its higher production temperature. This gives it increased durability. Sand-lime brick is heavier, making it difficult to install, as well as poor thermal insulation and low resistance to moisture. A certain plus is the lower price, but it is achieved due to the quality of raw materials. Fireclay brick is a refractory clay that does not deteriorate at high temperatures. Refractory is used for stoves and fireplaces, its working properties are fast heating and slow cooling.

In addition to the materials used for manufacturing, bricks differ in design features. They are full-bodied and hollow. The former are not susceptible to freezing, prevent moisture penetration, and are well suited for structures with heavy loads. Hollow bricks are used where lightness and good heat conductivity are required.

Features of single-row masonry

A brick house is a set of tightly connected small parts that create a monolithic structure. Any brick has three dimensions: length, width and height. When it comes to laying in one row, it is understood that the thickness of this row is equal to the largest dimension. In the standard version of the brick, it is 25 centimeters. Above twenty meters, a brick is not placed in one row due to a critical increase in the load. In such cases, multi-row masonry is used.

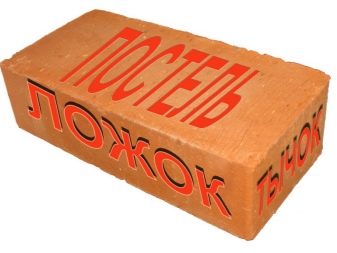

A brick is a piece of thermally processed clay in a standard shape. Each side of the product has its own name. The pastel is the largest side, the middle side is the spoon, and the smallest end is the poke. The modern quality of production is such that, before laying, it is advisable to make sure how exactly the sizes of different batches of the products obtained match. The quality of the future design depends on this.

1 brick masonry is used for the construction of small buildings and partitions. An extremely important point regarding the future quality of the building is the geometry of the brick. The edges must strictly diverge at 90 degrees, otherwise structural defects cannot be avoided. To enhance the strength of the masonry, vertical seams must be made with an offset. Reception of the displacement of the seam is called dressing. Laying a row with the smallest end face of the brick outward is called butt. If you lay the brick out with the longer side, this is a spoon laying.

Single row rule: the first and last rows are always bonded. In these cases, broken or damaged brick is never used. Chain masonry is a method in which the butt and spoon rows alternate all the time. Correct laying of the corners ensures the success of the rest of the details.When erecting a building, two corners are first made, which are connected by rows of bricks, then the turn of the third corner comes, which is also connected. The fourth corner creates a complete perimeter. Walls are always built around the perimeter. In no case should you build walls one by one.

For the construction of a pillar or a structure with a column, laying of 1.5-2 bricks is required. One-row masonry is applicable in the construction of the basement of the house. In this case, these are summer cottages for seasonal use, baths, small outbuildings. As already mentioned, single wall masonry is applicable only for the construction of low buildings.

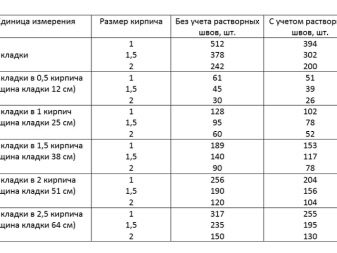

Payment

A standard brick is a product 25 centimeters long, 12 centimeters wide and 6.5 centimeters high. The proportions are quite harmonious. Knowing the size of one brick, it is easy to determine the quantitative need for its application. It is believed that if the mortar joint is 1.5 centimeters, at least 112 bricks will be used for each square meter of masonry. However, the brick that was available after production and transportation may not be ideal (with chips, etc.), plus the stacker may not have very good skills. In this case, it is appropriate to add 10-15% of the required amount of material to the calculated amount.

112 bricks per square meter turn into 123-129 pieces. The more experienced the worker, the fewer additional bricks. Thus, 112 bricks per 1 meter is a theoretical minimum, and 129 pieces is a practical maximum. Let's consider the simplest example of calculation. The wall is 3 meters high and 5 meters long, giving an area of 15 square meters. It is known that 1 square meter of single-row masonry requires 112 standard bricks. Since there are fifteen square meters, the number of 1680 bricks needs to be increased by another 10-15%. As a result, no more than 1932 bricks are required for laying the specified wall.

What should be the solution?

Mortar is a fundamentally important product that ensures the reliability of the structure. It contains only three elements: cement, sand and water, which can be mixed in various proportions. The sand must be dry and sifted. After the sand is mixed with cement and filled with water, the resulting mixture is thoroughly mixed. Water initially occupies 40-60% of the volume. The resulting mass must necessarily meet the plasticity requirements.

The higher the grade of cement, the less volume is needed. Also, the brand of cement determines its strength. M 200 can withstand a load of 200 kilograms in a volume of one cubic centimeter, M 500 - respectively 500 kilograms, etc. If the brand is below M 200, the solution of concrete and sand must be done one to one. If the concrete is stronger, the mortar is made according to the principle: one part of concrete for three parts of sand, and sometimes less. Wetting the brick prior to laying will create better adhesion.

Do not use too thin a solution. For the bottom rows, four parts of sand are used for one part of cement. However, when 60% of the wall has been erected, for greater structural strength, the concentration of cement should increase to the ratio: 1 part of cement to 3 parts of sand.

It is not necessary to make too much of a building mixture at a time, as the mortar quickly loses its plastic properties. It will not work to add water to it, since this will not change its qualities in any way. It should be borne in mind that when laying hollow bricks, the mixture will need much more, because in the process of application it takes up voids. In addition, the solution itself must be more rigid.

Ambient temperature affects the paver more than the properties of the mix, however it is best to work when the air is not cooled below +7 degrees Celsius. As the temperature falls below this threshold, the risks of deterioration in the properties of the solution increase.It can crumble, which significantly reduces the quality of the masonry in terms of strength. There are special additives for this case, but they will clearly lower the mood of the customer, since they will increase costs.

DIY brick laying rules and technology

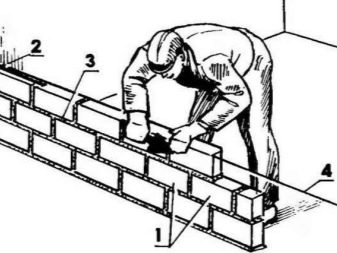

As in any serious construction business, here you first need to prepare the tools. They are usually as follows: a bricklayer's trowel, a hammer, a brightly colored construction cord, as a rule, a level, metal staples, a plumb line, a square. Brick and mortar from the beginning to the end of the process must be ready for use. There must necessarily be a container for making a solution, and even better - a concrete mixer. You can't do without several buckets for the ready-made mortar and a shovel for stirring.

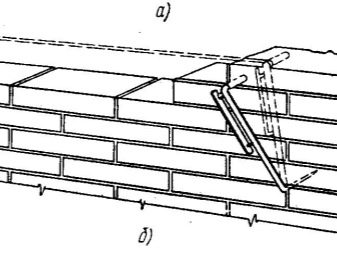

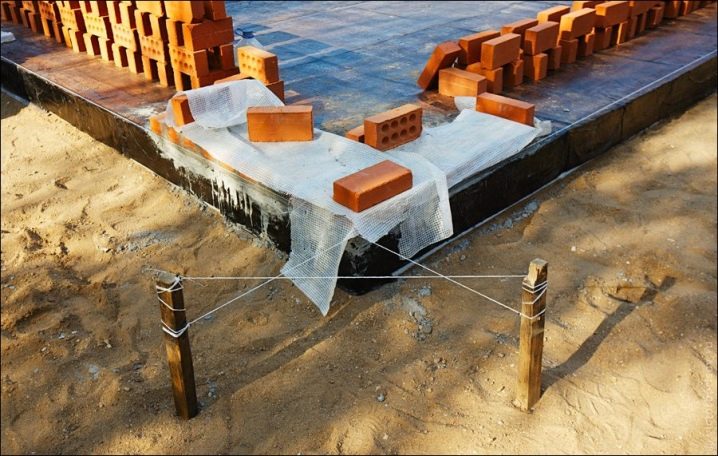

Before practical work with bricks, it is necessary to outline the contours of the future structure. Naturally, the foundation must be ready for laying. On the first row, it makes sense to determine the highest point of the working surface and mark it with bricks. It is required to maintain the laying plane at the highest point. For control, a cord stretched between the corners of the future structure is used. Beacons are also used (bricks in middle positions between future corners).

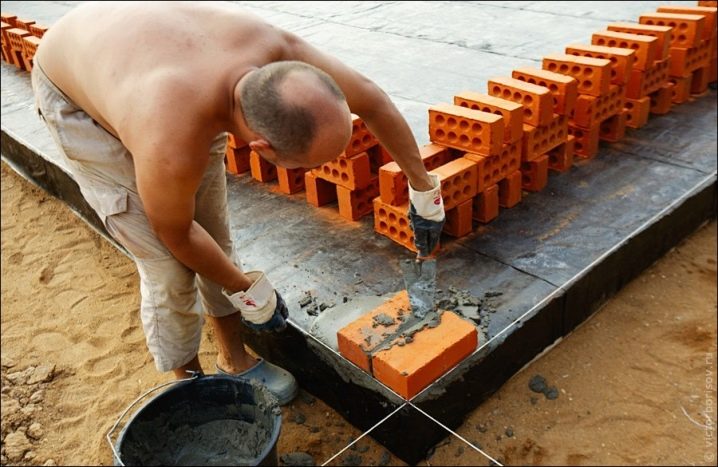

The solution is thoroughly mixed before use. Then he is laid out in a strip for a row. For the bonding method, the strip width is 20-22 centimeters, for laying with the spoon method, it is about half the size (8-10 centimeters). Before installing the brick, the mortar is leveled with a trowel. The installation of bricks is carried out from the corner. The first two bricks must fit on both sides of the corner at the same time. The mortar is usually smoothed from the center to the edge. The brick is laid exactly, after which a smooth surface is achieved by light tapping. These actions must be performed on each side of the corner.

The guide cord is pulled in such a way that it passes along the upper edges of the bricks laid in the corners throughout the future structure. The laying goes from corner to center in accordance with the position of the cord. The first row must be laid with the ends of the brick facing out. Further, the laying is carried out alternately, according to the scheme: perpendicular - parallel. After a certain number of rows (as a rule, there are no more than six), a reinforcing mesh is laid.

The vertical seams in adjacent rows should not coincide, otherwise this will not only lead to cracks, but also create the danger of collapse. Special attention should be paid to the construction of corners, as they form the basis of stability. After finishing laying the row, using a trowel, the seams are smoothed, in which the solution is pressed inward.

Professional advice

The first step is to choose which brick will be used. Basically, it is front or for interior masonry. The most famous classic red brick has not changed its parameters for a long time. In all other options, it is necessary to evaluate the specific dimensions of the product and the purpose of the structure. White (silicate) brick is considered the cheapest option. It does not differ from red in size, but weighs more. It is not recommended to erect buildings from it in one row above 8 meters due to the increased loads on the structure. The number of other types of bricks must be calculated according to consumption per square meter and compliance with the permissible load.

Before the start of laying, the brick must be moistened with water to improve its interaction with the mortar, this is especially important in hot and dry conditions. An important point - the masonry is always carried out from the inside of the building, a cord is used as a guide. Work starts from the corners of the future building. Here, maximum accuracy is required in combination with the use of a plumb line and level. The vertical and horizontal alignment of the paving planes must be constantly monitored, and the more inexperienced the paver, the more often.

Laying is always carried out from the corners and continues to lay along the perimeter, under the hand that is convenient for the stacker. The corners are ahead of the walls in height, not less than four rows. After the fifth row, it becomes necessary to constantly monitor the vertical plane with a plumb line. It is used from the outside of the structure.

Methods and schemes

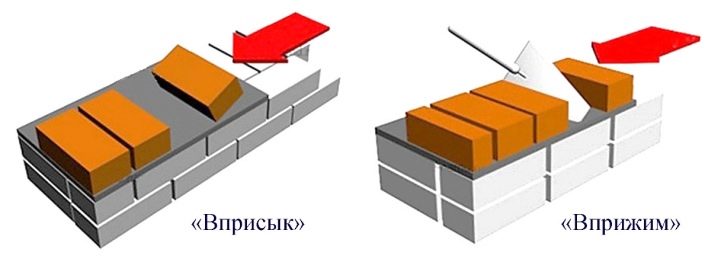

Laying walls in one brick has two techniques. The difference lies not only in the manipulations, but also in the density of the mortar used.

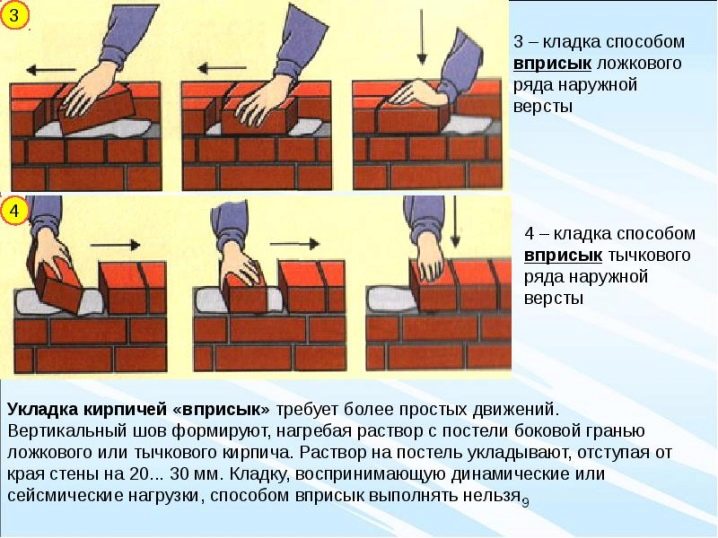

Seamless masonry "Vprisyk"

It is good for more liquid mortar and structures that are supposed to be plastered later. The solution is laid out immediately on the entire surface of the row. The applied solution is leveled with a trowel, the brick is laid, pressing it to the surface. Level the surface with the mobility of the brick. The thickness of the applied solution should not be more than 2 centimeters. At the edge, a gap is made without a solution of up to two centimeters. This prevents the solution from being squeezed out.

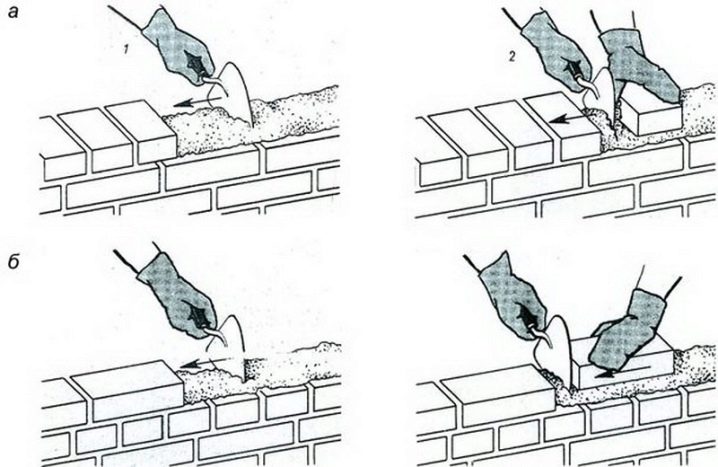

Masonry "Vpryzhim"

A thicker mortar is used here, because the surface will not be plastered. After applying the mortar, the brick is installed on the side. This provides lateral contact and vertical stitching. Here, accuracy and maximum accuracy are important, because in the event of an error, the quality of the work cannot be corrected. During the laying process, the brick is pressed against the trowel, which is then pulled out. The required joint width is ensured by pressure. In practice, horizontal seams are about 1.2 centimeters, vertical - 1.0 centimeters. In the process of work, you need to monitor so that the thickness of the seams does not change.

The method is quite laborious because it requires more movements. Efforts are rewarded by the fact that the masonry turns out to be denser.

The process of masonry and alignment of corners

Laying corners is a qualification test. Chain ligation alternates between butt and spoon rows, and frequent checking ensures quality work. The main requirement is constant control along the cord, with a square, the removal of planes with a plumb line and level. Strict adherence to the horizontal and vertical directions is necessary. Errors or inaccuracies in the corners are unacceptable. Leveling is done from corner bricks, each row is controlled separately.

Measurements need to be done the more often, the less experience the master has. For bandaging the joints of rows, where conditions do not allow the use of whole bricks, parts of the material are used that must be made on site. So, we can conclude that masonry in one row is available even for a beginner. The main thing is compliance with building rules, accuracy, good eye and accuracy. And, of course, the quality of the solution plays an important role.

For information on how to make the correct masonry in one brick, see the next video.

The comment was sent successfully.