All about the racks from the profile pipe

Currently, there is a wide variety of storage systems, with shelving being a popular option. Such structures can be made from a wide variety of materials, but models made from a profile metal pipe are considered the most durable and reliable. Today we will talk about the features of such structures and what types they can be.

Peculiarities

Shelves made of a profile pipe are distinguished by a special level of strength, they can easily withstand the largest weight loads. Wherein such products will not deform and collapse even after a long time of operation.

Metal storage systems can be built even with your own hands, since such materials are quite easy to install.... The metal is not exposed to the negative effects of sudden temperature changes.

Treated shaped pipes will also be able to withstand increased dampness. Often they are pre-coated with a special powder paint, which allows you to create an anti-corrosion layer on the surface, which also significantly increases the level of resistance and durability of such products.

The use of a metal profile pipe for the manufacture of racks meets all the basic requirements of fire safety. Indeed, unlike wood, metal will not ignite and burn.

A rack made of such a square pipe will not require special care. A damp cloth will be sufficient for cleaning. You can simply wipe all surfaces with it, even without using special detergents (they, as a rule, are taken with strong dirt).

Most often, such models are placed in workshops and garages. They will make it possible to place all parts and tools in one place, while freeing up free space in the room. Sometimes they are built for greenhouses. This will allow more plants to be grown there.

The metal profile must be treated with a protective compound that will not allow rust to form on the metal surface, as well as some other additional solutions to extend the service life.

Advantages and disadvantages

Such metal storage systems have many important advantages, we will highlight the most significant of them.

- High level of reliability and durability. These structures can easily withstand heavy loads, and at the same time they will not break or deform.

- Wear resistance. Products from a metal profile, even with intensive constant use, will be able to retain all their properties and neat appearance.

- Convenience. In such storage systems, you can place items made from a variety of materials.

- Stability. A properly processed metal profile will practically not be exposed to the negative effects of temperature extremes and excessive moisture.

- Durability. Metal shaped pipes can serve as long as possible even in rooms with a high degree of dampness, as well as in poorly heated rooms.

- Mobility. Racks made for home use, if necessary, can be independently moved or disassembled without much effort.

- Attractive exterior design. Structures made of such material look the most accurate and aesthetically pleasing. In addition, unlike solid wood shelving, they are not as bulky.

Among the disadvantages of such metal structures, one can single out the higher cost compared to systems made of other materials. It can also be noted that the manufacture of products from a metal base will be a little more difficult than systems from wood.

Views

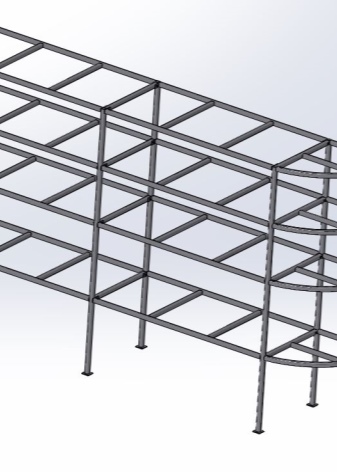

These metal storage systems can be of various types. So, they can be divided into several groups depending on the design features of the product.

- Collapsible rack. This robust design is considered fairly straightforward. Collapsible models can be assembled by yourself without the involvement of professionals. They must be made from specially processed profiles. All individual elements of the system are connected to each other using special fasteners-mechanisms, which, if necessary, can be removed with almost one hand movement and installed back, folding or unfolding them into one single structure. Often, such samples are equipped with additional plug-in shelves that come in one set with the main part. They can also be easily fixed by yourself. Such varieties are mainly used in various commercial and warehouse facilities, but sometimes they are also located in outbuildings and garages.

- Shelf rack. These models are considered the most popular option. Such storage systems have a collapsible design. At the same time, they are equipped with robust side frames, as well as special load beams and additional elements. Shelves of this type can easily support significant weight. For the manufacture of the shelves themselves, chipboard plywood, zinc-coated steel sheets can be used.

Shelf options are more often placed in supermarkets and warehouses. After all, they allow you to place a large number of objects next to each other, while maintaining open access to them. On such shelves, oversized cargo is mainly laid out.

- Front storage system. This design is versatile, so it can be used in rooms for a wide variety of purposes. In this case, the goods can be stored on special wooden pallets. Sometimes special pallets are also used. Such designs make it possible to use the working area as efficiently as possible and conveniently place all objects, there will always be open access to them.

- Printed constructions. These storage systems do not have aisles. They are rarely used for a home or garage, more often they are present in retail or warehouse facilities and are used to store goods. Printed models are created from vertical profile frames. They allow you to easily adjust the distance of the cross beams, the height of which can be changed independently if necessary. As in the previous version, the constituent elements of such racks are pallets on which items are placed.

- Mobile shelving. These options consist of various frontal metal sections that are firmly connected to each other. Such models are equipped with special movable platforms. There are no openings between the rows.

- Console storage systems. These metal racks are the best option for storing items of considerable length. They provide quick access to items. Console samples can be easily made by yourself at home.

- Corner models. These racks are installed in the corner of the room. In this case, the free area will increase. In this case, the width, height and length of the shelves can be very different. Such systems are often located in rooms, offices, they allow you to conveniently place and store documentation and books. As a rule, corner options do not differ in large dimensions and weight. They are quite lightweight and easy to assemble and assemble.

- Wall-mounted structures. These racks are located along the walls. They are often installed in garages.They are considered a practical and most convenient option, the models allow you to use the space in the room as efficiently as possible. In addition, the structures are distinguished by a more accurate and aesthetic external design and reliability. The products fully meet all safety requirements, they are as easy to use as possible.

Such racks may differ from each other depending on the dimensions of the profile pipes from which they are made. Often they are made from such elements 20x20, 20x40, 40x40 millimeters (a 20x40 metal pipe is considered the standard option).

How to do it?

If you need a shelving unit for a house, garage or workshop, then you can either purchase a ready-made structure, or make it yourself at home, even without using welding. The entire manufacturing technology includes several mandatory steps.

Instruments

First you need to prepare all the necessary devices for this. So, you will need to take the following tools and materials:

- grinder;

- galvanizing (you can use a special powder-type paint);

- nuts, bolts;

- welding machine with electrodes;

- profiles and rollers.

If you will also use wooden inserts and pallets for metal shelving, you will need plywood, a hacksaw, strips for the end pieces, nails, a screwdriver and special water-repellent paints.

Blueprints

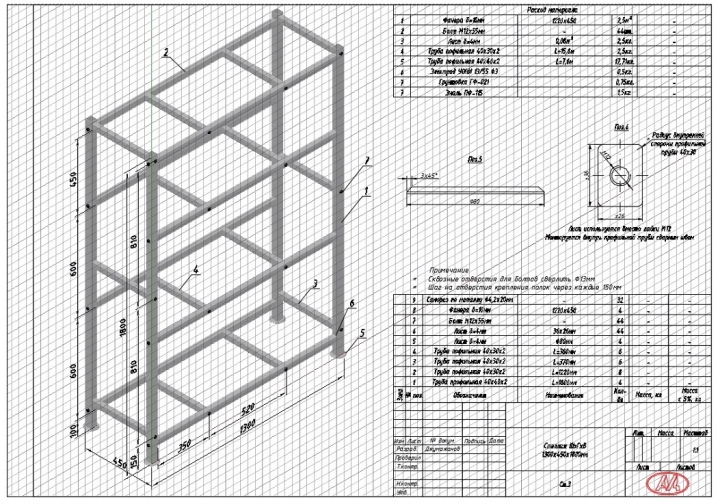

Before proceeding directly with the manufacture itself, you need to form a detailed drawing of the future product. The selected drawing should indicate all the dimensions that must be adhered to during the manufacture of the structure. On paper, it is better to immediately depict a volumetric model of the future rack.

Assembly

In advance, you should prepare the shelves that will be used in the future storage system. The standard shelves are 50 cm high and 80 cm wide. Wider surfaces will need to be fixed at the bottom of the structure. Their optimum thickness is 5-7 cm.

First, the main frame department is assembled. To do this, you need to firmly fix the brackets for the shelves to the metal profile. The uprights can be fixed with conventional bolts. Sometimes they make a welded homemade rack, in which case, instead of using bolts, you need to weld the joints.

The profile can be fixed to the wall covering using self-tapping screws. Such a structure is as stable as possible, since it will not stand alone in the room, but will firmly be fixed in the wall.

After that, the shelves are inserted into the resulting frame using brackets. Cross-shaped struts are fixed on the sides. Then you should check the level and degree of curvature of the rack.

The finished structure must be covered with a zinc compound, which will significantly extend the operational life of the metal structure. Also, at the final stage of manufacturing, the surface is coated with a primer and powder paint.

For information on how racks are created from a profile pipe, see the next video.

The comment was sent successfully.