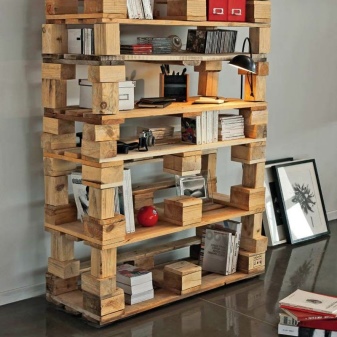

Pallet racks

Over the past few years, people have increasingly preferred furniture with creative designs. An unusual shape, the presence of many complex elements - all this is characterized as originality, and most importantly, practicality. Each recess in the furniture is intended for use. Today these items are made from shipping pallets. At first glance, it may seem that it is impossible to make a high-quality and beautiful headset out of such a consumable. But it is not so. It is enough to show imagination, desire, creativity, well, and stock up on some tools. Moreover, you can make up a one-piece set from several separately assembled racks.

Advantages and disadvantages

Pallets are bases designed for the transportation of bulky massive cargo. Colloquially, products are called pallets. High quality wood is used for their manufacture.

But even the most durable wood is not able to withstand constant high loads. That is why the shelf life of pallets is no more than 2 shipments.

After serving the specified time, the pallets are sent for recycling, even if the boards themselves are in excellent condition.

Modern furniture designers have paid attention to pallets due to the strength of the material, environmental friendliness and low price. Thanks to these characteristics, it was possible to launch a new trend of budget furniture that meets high quality requirements.

Another outstanding advantage of pallets is their ease of reconstruction. There is no need to file the boards, cut them - they are all the same size, which, incidentally, is ideal for creating household furniture. Of course, pallets differ in size and type of construction - these factors affect the final dimensions of the manufactured furniture and its appearance.

The production of pallet bases is on the stream today. At the same time, modern pallet designs are divided into single-layered and double-layered ones. Euro pallets familiar to all are single-layered products with 4 base boards. They are considered the optimal solution for the manufacture of beautiful and durable furniture designs.

Some people believe that shelving, cabinets and other furniture options constructed from pallets will not be able to fit into the finished interior. This opinion is wrong.

Wood is such a versatile material that all products made from it are ideal for any room style.

But, by connecting imagination, it will be possible to supplement the finished structure with a certain decor, which will bring the product as closely as possible to the design of the home. Racks made from pallets will be the best option for decorating a country or Provence-style room.

Design options

Today, pallets are very popular in the arrangement of houses, apartments and summer cottages.

Many garage owners create designs from this consumable where tools and other work equipment can be stored.

The simplest racks of pallets attached to the front of the house can be used to grow flowers. In industrial premises, such racks are used in warehouses. Various tools and items necessary for work are placed on them.

Modern furniture designers note that pallet racks are divided into several types.

- Floor standing - they are distinguished by a high level of strength, stability, massiveness, and have sufficient capacity. Such racks require capital fixation to the wall.

- Hinged - they are made from no more than 4 shelves. They are mainly used for arranging small rooms or premises. The main advantages of hanging racks are small size and ergonomics.

- Mobile - such models of shelving are lightweight and have compact dimensions. On the underside, they are equipped with a wheelbase that allows transporting the rack cabinet from place to place.

Selection and preparation of pallets

The weight of a standard pallet is approximately 15 kg. The exact figure for the mass depends on the dimensions of the product. Today they are of 2 types:

- 1200x1000x120 mm;

- 1200x800x120 mm.

An important characteristic of pallets as a raw material for making furniture is the strength of wood. According to the standard, one pallet is designed to transport cargo weighing up to a ton.

What is most interesting is that after such a load, most pallets do not have even minimal deformation. They are used for the manufacture of shelving.

Most people do not fully understand why they choose Euro pallets to create furniture designs. The answer is very simple. It is the Euro pallets that undergo a special phytosanitary treatment. In Russia, such stringent requirements are not imposed on pallets. Accordingly, they are less reliable and less durable.

By itself, phytosanitary treatment is divided into 3 types.

- Drying. Pallet boards are placed in a chamber where the temperature exceeds 60 degrees. The constant movement of air dries out the wood, due to which it does not rot or crack under heavy load.

- Heat treatment. In this case, assembled pallets are sent under the heat effect. The high temperature dries out the tree and destroys the pests living in it. But, unfortunately, it is impossible to uniformly process the wood base with this type of exposure. That is why the quality of pallets often suffers.

- Use of fumigators. The wood surface is treated with methyl bromide, which destroys harmful microorganisms. However, after treatment with this substance, toxins remain inside the wood crevices. That is why such pallets cannot be used to transport food and baby products. They are also not recommended for home furnishings.

Well, now you need to figure out how to prepare pallets for the upcoming assembly of the rack structure.

- First, you need to clean the wood surface of the Euro pallet from dirt and dust. Remove rough areas of wood with a sander.

- At the end of rough processing, you need to bring the surface of the wood to a smooth state. To do this, use fine-grain sandpaper.

- If you intend to install the rack outdoors or in a room with a low temperature, the wood base must be treated with special moisture-repellent impregnations.

Manufacturing schemes

After processing the pallets, you can start assembling a well-thought-out rack structure and do it yourself. First of all, it is proposed to look at the simplest version. For work you will need:

- several pallets;

- wooden slats;

- holders;

- brackets;

- roulette;

- scrap;

- saw;

- grinder;

- sandpaper;

- self-tapping screws.

Well, now the process of work itself.

- The upper part of the pallet must be disassembled. Scrap will come to the rescue.

- The removed boards must be sawn. In this case, several lengths are required: 9 boards of 110 cm, 2 boards of 45 cm, 2 boards of 25 cm.

- The sawn elements must be sanded.

- Boards of 110 cm must be laid out close to each other. For uniqueness, you can shift the lengths of the boards slightly up or down.

- Rails are installed perpendicular to the boards and screwed with self-tapping screws. Each board must be screwed to the joint support.

- It is necessary to turn the workpiece over and install the pairs of brackets in three different positions.

- Planks of 45 cm are fixed to the first pair of brackets.

- Planks of 25 cm are fixed to the two remaining pairs.

- The finished rack must be painted or varnished. Suspension elements are attached to the slats located on the back side, allowing the structure to be installed on the wall.

Next, we propose to consider another interesting version of the rack, which is a bookcase. For work you will need:

- several pallets;

- sandpaper;

- furniture nails;

- saw;

- grinder;

- scrap;

- self-tapping screws.

Manufacturing process.

- It is necessary to disassemble the upper part of the pallets.

- Use a sander to smooth the planks.

- Cut the prepared boards to make 24 bases 20 cm long. They will be shelves.

- Several planks need to be cut into 24 pieces 25 cm wide.

- The assembly of blocks begins. You will need to measure the full length of the boards and put a mark at the midpoint. At the ends of the board, screw the workpieces 25 cm apart. The same is done at the midpoint.

- Take the next long board and fix it on the other side. This creates a long section with a shelf positioned at the midpoint. According to a similar scheme, 3 more identical frames are made.

- The creation of smaller blocks begins. The 2 boards are folded together, aligned as close as possible. Further, measurements are carried out and division into 3 identical segments. Small blanks are screwed to the ends of the boards, the same ones are placed inside the section. Several more frames are assembled in a similar way.

- Further, one section is connected to another, preferably with an offset, in order to give the design more originality.

- Larger workpieces are attached to small sections.

- Thus, the assembly of the original design takes place. The final stage involves painting the rack or varnishing it.

How to make a rack from pallets for a garage, see the video.

The comment was sent successfully.