How to make a book rack with your own hands?

Modern hardware stores offer a huge number of different designs for storing books. However, nothing fits in better than custom-made book shelves. You do not need to have carpentry skills or extensive professional experience for this.

Required tools and accessories

First you need to figure out what you need to find or purchase in the nearest store for the upcoming work.

A bookcase is usually based on wood, but other materials (parquet boards, drywall, laminate, etc.) can be used. They also use metal, plastic and glass, but it will be almost impossible to work with them at home. In addition, you should not resort to using chipboard, since the material contains toxic compounds that can spoil health. When choosing raw materials, you can focus on its compatibility with the interior and the maximum load-bearing capacity, taking into account the weight and size of the books that will be on the shelves.

So, for the manufacture of the structure you will need:

-

boards 3 cm thick (± 1 cm);

-

slats (at least 4x4 cm, more is possible);

-

support for shelves (holders, wooden blocks, metal corners);

-

plywood (for shelving walls);

-

a set of self-tapping screws or screws;

-

joiner's glue;

-

varnish and a brush for it;

-

drill, jigsaw and grinding machine;

-

screwdriver, hammer;

-

pencil and tape measure (for marking).

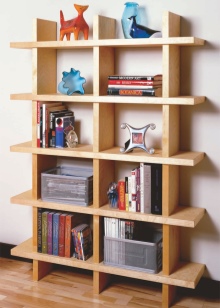

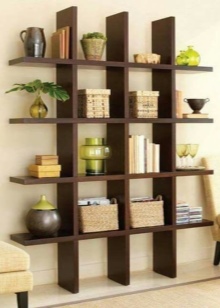

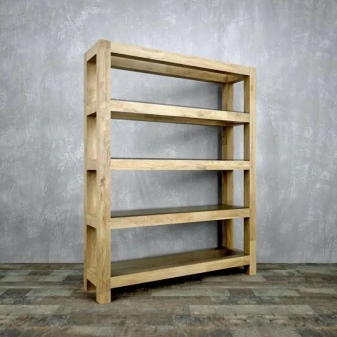

The number and type of materials used may vary depending on the desired design of the future rack. They can be of different types: open and closed, collapsible and non-collapsible, sectional and transformable. As original ideas, you can propose to use asymmetry, take some object (tree, diamond, ladder, and so on) as a form - in general, everything that fantasy reaches.

In addition, the rack can be wall-mounted or placed on the floor.

This article is about a simple floor structure that everyone can make on their own at home.

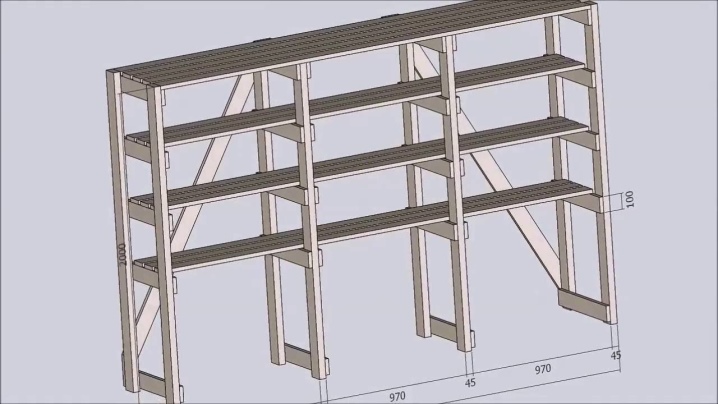

Drawings and dimensions

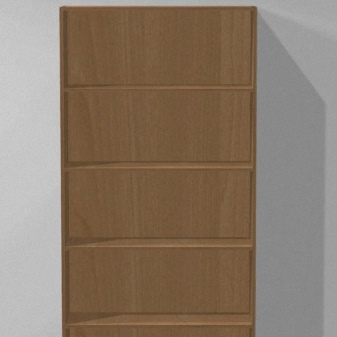

The first step is to develop a project for the future shelving. To do this, you need to think over the design of the structure, its dimensions and draw it in proportion. The drawing can be depicted in special computer programs that allow you to build a 3D model and see how the rack will look in a given space. The second option is to use the traditional method, which means arm yourself with paper, pencil and ruler. But you need to understand that self-manual sketching of the diagram will take much more time and effort.

Many are at a loss and do not know where to start. In this case, you first need to think about where the rack will stand. For example, if a person has an entire home library at their disposal, then the size of the shelves will be appropriate. And in a dacha, where there is a small amount of books and magazines, a small locker will do. The design is also made individually for each person, so it is better to rely on the compatibility of the rack with the surrounding interior.

If this is the first experience in the manufacture of any furniture, then it may not be worthwhile for one to immediately take up the business, but involve family members or friends to help. It will be much easier and more fun.

Step by step diagram

After preparing the drawing, you can start creating a do-it-yourself book rack.

The first step is to apply the markings from the project to the prepared material and cut it into the required number of parts. It is better to double-check all the calculations and put marks several times, so as not to get upset once again because of the spoiled material and loss of time.

Frame

It is customary to make the base from a board, the thickness of which is not less than 3 cm. From the bottom, you need to nail down, using nails and a hammer, longitudinal boards, and between them transverse boards. Thus the wooden structure will become much stronger and more reliable.

Next, the back wall is made. For this, plywood is taken (building cardboard can be used). In the drawing, the length and height of the rack have already been determined, so you just need to cut the element according to the specified parameters.

The corners of the wall must necessarily be straight (90 °), otherwise the structure will be skewed.

Self-production of the element is not required if you take ready-made material of the required dimensions in the store.

Sidewalls execution. To save money, they are very often not included in the design, and instead of them, ordinary bars are used. But still, consider this stage. For the manufacture of the sidewalls, again, according to the drawing, cut off the required height and length from plywood or beams. After that, on their inner side, mark the places for future shelves, and cut the grooves. It makes sense to reinforce corners, holders or trims of beams in these places, since then it will be more difficult to do this. Now you can install the side walls by screwing them in with self-tapping screws. To make it easier to fix the second sidewall, it is worth turning the structure on its side. At the same stage, the back wall is fixed (if it is included in the structure). It saves the rack frame from skewing during further operation.

Installation of boxes and shelves

When the frame is completely ready, you can start cutting and strengthening the shelves. According to the standard sample, the dimensions of the shelves are equal to the parameters of the base.

If in the manufacture of the frame the corners have already been screwed, then all that remains is to screw the shelves to the sidewalls using self-tapping screws. Or make 8-12 mm holes for screws - and use them.

Finishing

At the final stage, it remains to process the structure. Surface treatment is an important point that must not be forgotten. It will help preserve the durability of the furniture and prevent the wooden shelving from starting to rot. The processing is easy to carry out yourself without anyone's help. For this, various methods are used: sanding with further painting, coating with linseed oil, wax or varnish, pasting with paper, and so on.

For painting wood, oil, alkyd or acrylic paints are usually used. Each part should be painted over with two coats of paint and one coat of varnish. In addition, staining (on water, oil, alcohol and wax bases) or potassium permanganate is used for processing.

As additional ideas, the shelving unit can be decorated with appliqués, stickers, drawings and many other things. For convenience, you can attach the wheels (just turn the rack over and screw them using a screwdriver and screws). And some, after careful processing of wood, even decide to glaze open shelves. In this business, everyone should be guided by their own taste and capabilities.

Advice! Even after high-quality and detailed processing, it is not the best option to put the rack in a place with high humidity or in front of a window on the south side. Such long-term exposure will negatively affect the condition of the material.

The homemade shelving unit described in the article will become not only a practical and attractive part of the interior, but will also be the best experience for beginners in this business. If everything worked out, then the next step is already possible to swing at more complex models.

How to make a rack with your own hands, see the video.

The comment was sent successfully.