What are CNC laser machines and how to choose them?

For the manufacture of souvenirs and various advertising products, furniture and much more, which not only helps to equip life or another environment, but also makes them more beautiful, you need a CNC laser machine. But you still need to choose the right one, as well as study the capabilities of the unit.

Device and principle of operation

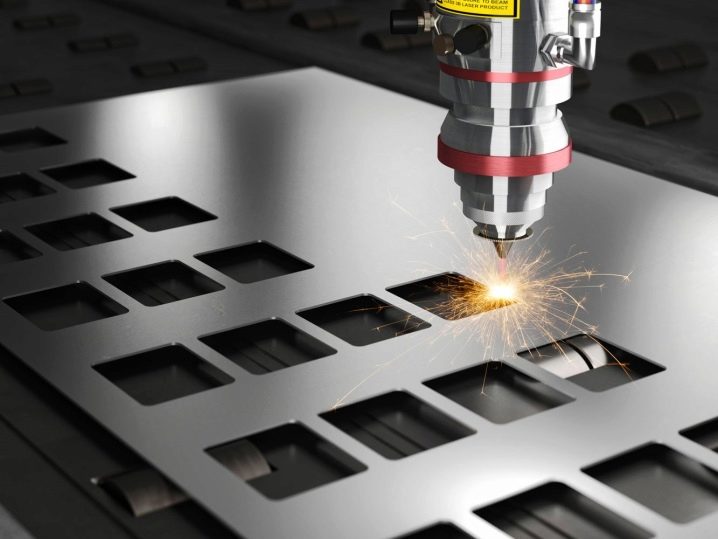

Laser cutting is considered universal, and this is the main advantage of the technology used by the machine. The mechanical method is almost always associated with metal losses, and its high performance does not distinguish it. The thermal method is not applicable to everything, but laser cutting is suitable in all cases. And this process is similar in form to a mechanical one, only a laser beam acts as a cutter, it penetrates the workpiece and cuts it. It acts like a plasma arc, a source of heat, but the thermal action zone is very small.

The laser cut materials not extremely thin, but even combustible, such as paper or polyethylene.

How the laser beam behaves:

- melts - this applies to plastic and metal, while it works in a continuous radiation mode, for better quality, the process is accompanied by gas, oxygen or air blowing;

- vaporizes - the surface heats up to boiling rates, therefore the material evaporates (and does not accumulate with chips or dust), the mode is represented by short pulses with high power;

- decomposes - if the material does not demonstrate high resistance to thermal action, and the substance can decompose into gases without melting (but this does not apply to toxic components, this method is not applicable to them).

For example, PVC glass is cut only mechanically, otherwise laser processing will be accompanied by the release of toxic substances.

And now closer to CNC - this control is understood as a package of programs that generate control impulses to electric drives. Such a package guarantees the accuracy of execution, the ultimate for this technique. The accuracy of cutting and drawing lines on a CNC laser machine is virtually unparalleled.

What is such a machine good for:

- material consumption is minimal;

- very complex configurations can be cut;

- there are no restrictions on the choice of material;

- the edges can be kept sharp;

- the speed and precision of cutting will compensate for the high price of the equipment very soon.

Among other things, such a machine simplifies the process of creating a model. And the created project is loaded into the memory of the computer that serves the machine and, if necessary, is corrected. All features of the material are taken into account.

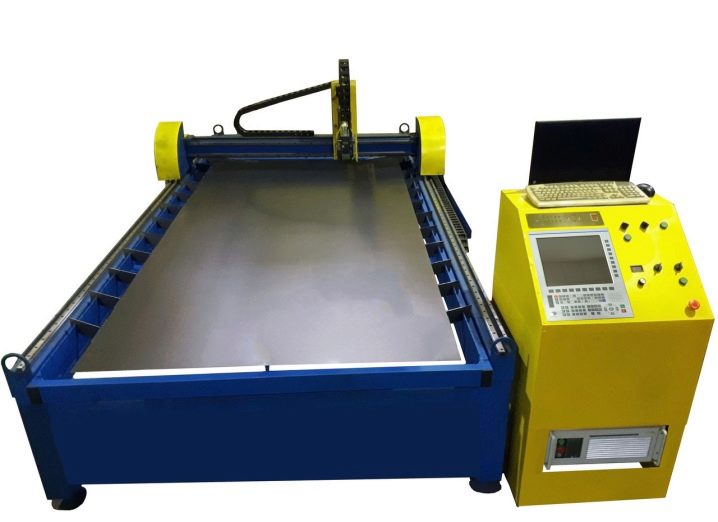

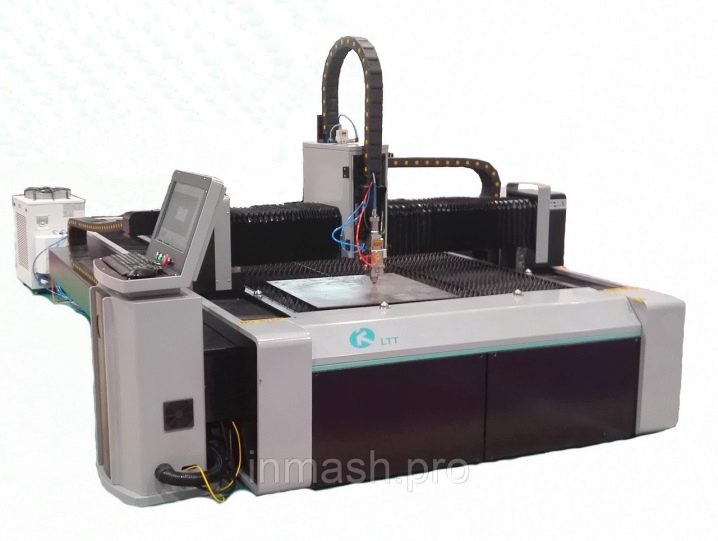

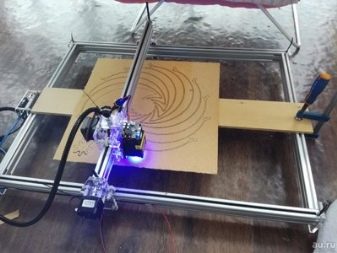

Views

The machines can be table-top and floor-standing. Desktop machines are also called mini-machines. It can be placed anywhere in the workshop (even in an ordinary apartment), if, of course, there is an extractor hood, not dusty or dirty. The power of such devices is not particularly high, up to 60 W, but the machine is designed for the manufacture of small-sized and non-metallic workpieces. Floor machines are used where work is being built at high speed, where the material can be flat, volumetric, and wide-format.

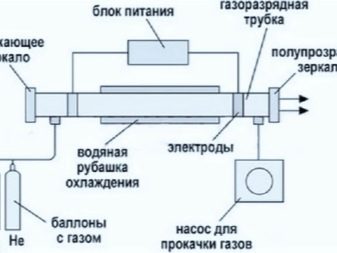

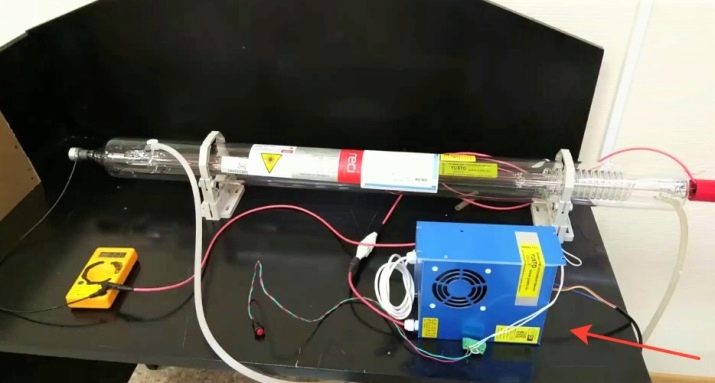

Gas

These are the most powerful continuous-wave lasers. Energy is transferred by nitrogen molecules to carbon dioxide molecules. With the help of electric pumping, nitrogen molecules come into an excitation and a metastable state, and there they transfer this energy to gas molecules. The carbon molecule gets excited and at the atomic level emits a photon.

What are CNC gas laser machines:

- non-flowing with sealed pipes - gas and ray path are concentrated in a sealed tube;

- with fast axial and transverse flow - excess heat in this device is absorbed by the gas flow passing through external cooling;

- diffuse cooling - in these types of CNC, the gas is placed between special water-cooled electrodes;

- with a transversely excited medium - its features are high gas pressure.

Finally, there are gas-powered rigs, the power of which is several megawatts, and they are used in anti-missile installations.

Solid state

Such machines will ideally cope with metals, because their wavelength is 1.06 microns. Fiber cutting machines are capable of producing a laser beam with seed lasers and glass fibers. They will cut metal products well, cope with engraving, welding, marking. But other materials are not available to them, and all because of the wavelength.

This characteristic - solid and gas - division into types, which can be called "second". That is, no less important than the division into floor and table machines. And you should also talk about compact laser markers: they are needed for engraving on some bulky items, for example, on pens and key rings. But even small details of the pattern will come out clear, and the pattern will not be erased for a long time. This is ensured by the biaxial design of the marker: individual lenses in it can mutually move, and therefore the laser beam generated by the tube is formed in the already two-dimensional plane and goes to any point of the workpiece at a given angle.

Top manufacturers

Rabbit will definitely be among the leaders on the market. It is a Chinese brand that represents models with economical energy consumption, increased working life and optional CNC installation.

What other brands are leading in this segment:

- Lasersolid - offers compact, not very powerful, but easy-to-use and more than affordable machines that process small parts made of leather, plywood, plexiglass, plastic, etc .;

- Kimian - also produces mainly machine tools for processing small parts, includes laser tubes with high performance in the design;

- Zerder - a German brand that does not show the highest competition in the device of machine tools, but takes a price;

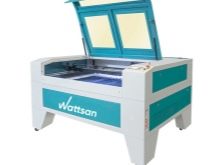

- Wattsan - but here, on the contrary, prices will not be lifting for everyone, and this is because this machine is ready to work with very complex models.

- Lasercut Is a very popular company supplying the most popular models from top manufacturers. It has established itself in Russia and abroad. Many models offered by the company are bought by representatives of small and medium-sized businesses: they are chosen for high cutting speeds, a wide range of options, and ease of maintenance for machines of this brand.

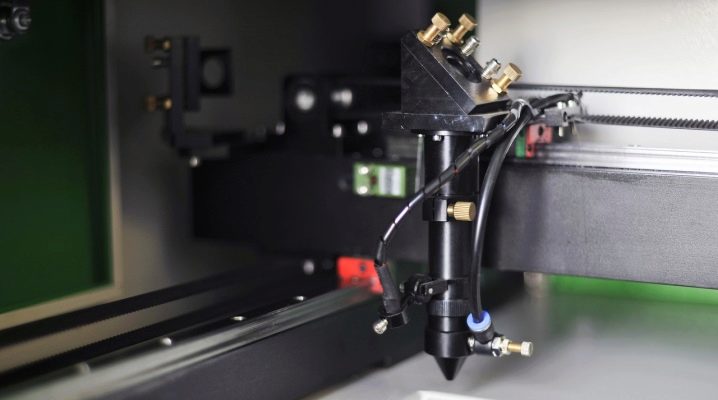

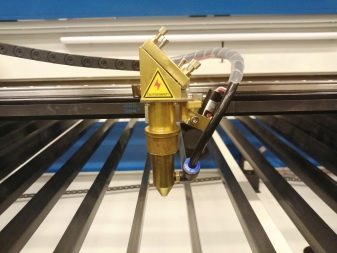

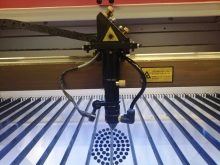

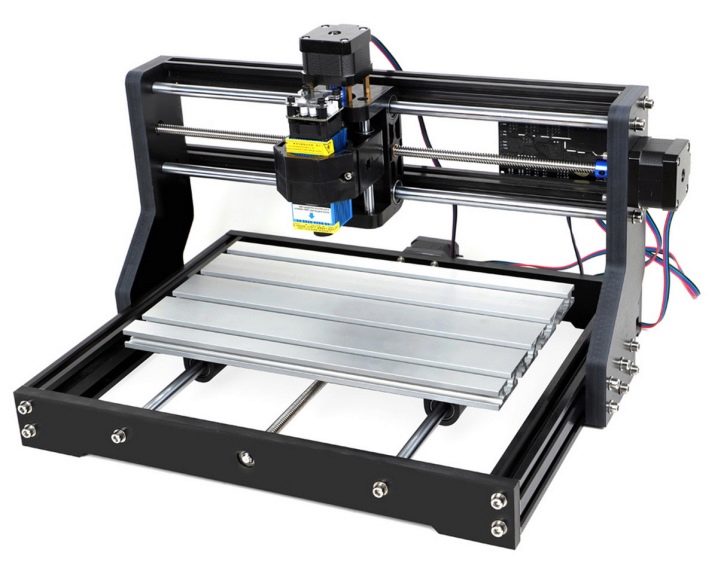

Components

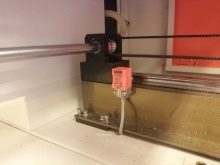

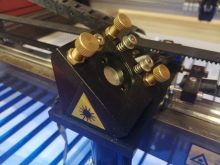

To begin with, it is worth considering the very design of the machine. It consists of a fixed part - the bed, everything else is placed on it. It is also a coordinate table with servo drives that move the laser head. It is essentially the same spindle on a mechanical milling machine. And it is also a work table with a mounting scheme, a gas supply module (if the machine is gas powered), an exhaust hood and, finally, a control module.

What accessories may be needed for such a device:

- laser tubes;

- power supplies for tubes;

- stabilizers;

- cooling systems;

- optics;

- stepper motors;

- toothed belts;

- Power supplies;

- rotary devices, etc.

All this can be bought at special sites, you can choose both a replacement for a failed machine element, and as a device modernizer.

Selection rules

They are composed of several criteria. Having dealt with each step by step, it is much easier to find the desired unit.

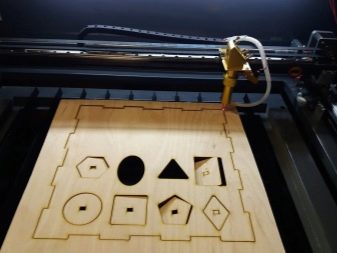

- Work material. So, laser technology can also work with hard sheet metals, but this is a completely different price segment of the technology - and therefore such material can be taken out of the brackets. But the processing of fabrics, wood, polymers can fit into the concept of a machine for a home workshop. And the tree is probably in the first place (as well as its derivatives). The machines can also work with composite materials, for example, with laminate. The thicker the material, the more powerful the tube should be. And the more powerful the tube, the more expensive the machine.

- Dimensions of the processing area. We are talking about the size of the treated surfaces, and the convenience of loading them into the working chamber of the device. It is good if the package includes a vacuum table, it better fixes the material for processing. But if the task, for example, is engraving for key rings and badges, a machine with a small closed volume will suffice. And it's good if small pieces of material are cut in advance for it.

- Processing type. That is, what exactly the machine will do - cut or engrave. It is necessary to understand that not all machines can do both. For cutting, the machine needs more powerful and faster, it will achieve high productivity. The faster and better the cut is carried out, the faster the process will be, and serious circulations can be planned. If the unit is needed more for entrainment, then a low-power one is enough, and usually such devices provide for engraving and cutting of thin materials.

- Complete set + basic components. The mechanics and kinematics of the equipment, the element base of the optics, and the control controller are important here. To engrave on cardboard and paper, cut thin plywood sheets, a simple and single-function machine will do just fine. But if you want to provide a wider range of services, you will need a universal unit that can do several tasks during a run. These devices usually have an auxiliary interface that can run commands through a flash card.

- Country of origin, level of service. The search almost always starts with Asian e-shops, as prices are reasonable there. But sometimes it is risky, if only because returning a faulty machine to the seller is often an impossible mission. In this sense, working with a local manufacturer is much easier, and there will be predictably fewer problems with the service.

It seems that we figured it out - the main thing is that there are options, which means that it’s more interesting to choose.

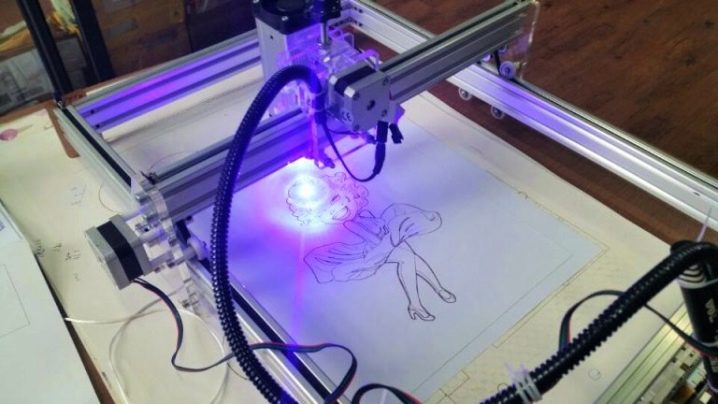

Possibilities and areas of use

The scope of such equipment is not so small. For example, it is very actively used in advertising products. Signboards, various acrylic inscriptions, figures of characters - this is only a small part of what is done with the help of such machines. Probably, most of the small business projects related to the acquisition of CNC laser machines go exactly in this direction. Machine tools are also used in light industry: in the sewing industry, for example, machines help to create patterns, patterns on the material.

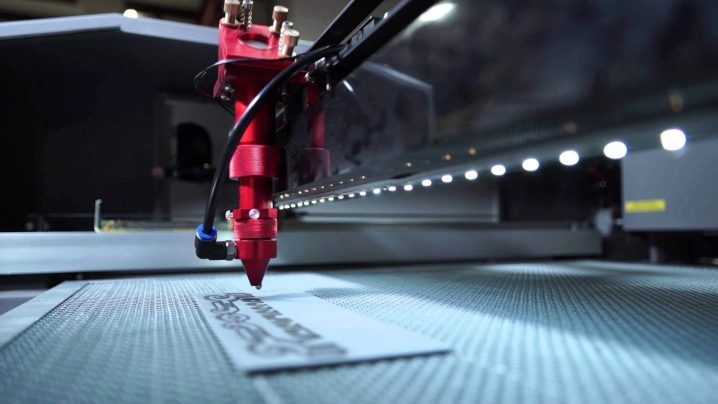

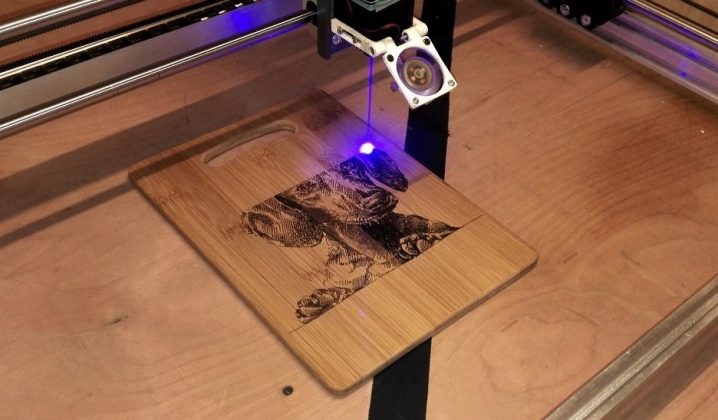

It is impossible not to mention metal processing, but this is already a branch of space, aircraft and automobile construction, military, shipbuilding. Of course, here we are no longer talking about business and small projects, but about government requests, etc. Finally, where can we go without wood processing - for these purposes, the laser unit is more than good. It is possible to engage in wood burning with the help of such a machine, and to cut and manufacture cabinet furniture parts.

And if we go back to small business, then there is activity in the production of souvenir and gift products. The pace and volume of manufactured items are growing, they are getting cheaper, and sales are gaining new opportunities.

Also, using laser equipment, you can make stamps and seals.

All this is just some of the areas where such machines are actively used.They are being modernized, manual production is increasingly being replaced by robotic ones, it is becoming more accessible, and it becomes easier for creative people to embody their ideas, not without the help of innovative equipment.

The comment was sent successfully.