Chiller-fan coil: description, principle of operation and installation

Chiller-fan coil units are increasingly replacing the usual gas-filled cooling systems and water heating circuits, allowing the medium to be supplied at the desired temperature depending on the season and other factors. With the help of such equipment, it is possible to maintain an optimal indoor climate all year round, without stopping operation, while there are no restrictions on the height and size of objects. The principle by which the operation of the system is built is as simple as possible: it acts by analogy with water heating. The burner or heating element of the heater here is replaced by a chiller or its combination with a boiler, capable of giving the required temperature to the substance circulating through the pipes.

How is such an air conditioning system serviced? How much more efficient is it than conventional split systems and can it replace them? What does the installation diagram of chillers and fan coil units look like? Answers to these and other questions will help you better understand the advantages and disadvantages of such complex equipment.

What is this system and how does it work?

A fan coil chiller is an interconnected piece of equipment that has a main element that is responsible for heating or lowering the temperature of the medium, and auxiliary components that transport the medium. The principle of operation is similar to that used in split systems, with the only difference that water or antifreeze based on it moves in fan coil units instead of freon.

This is how ventilation and air conditioning systems work, aimed at cooling. But splits have their own challenges. When carrying out refrigeration, they supply gaseous substances to the pipes and are regulated by certain standards for the remoteness of the main unit from individual internal ones. The chiller-fan coil pair is distinguished by the absence of such restrictions, since water or antifreeze based on it acts as a heat carrier or antifreeze, the length of routes regulated by safety requirements can be unlimited.

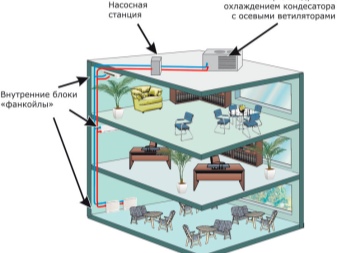

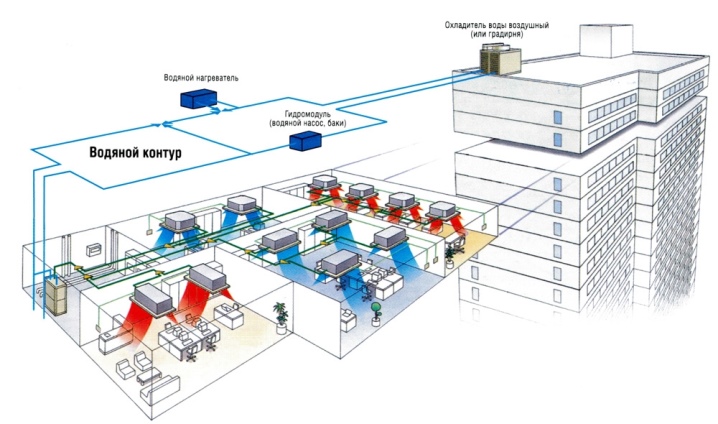

In fact, a chiller is a large air conditioner through which the medium flows through the evaporator. Water or antifreeze is piped to fan coil units installed indoors. Typically, the cooling system elements are of the cassette type and are mounted on the ceiling. Heating and universal fan coil units are available for floor or wall mounting and are fixed as low as possible.

Chiller features

All existing chillers are divided into 2 large groups: absorption, the most expensive, with limited use and large dimensions, and vapor compression. This type is used most often, including in low-rise construction and in multi-storey industrial, commercial buildings. There are three types of vapor compression chillers according to the installation method.

- Outdoor. They have axial fans for air cooling.

- Internal. In them, cooling is carried out with the help of water, air movement is carried out using a centrifugal fan.

- Reversible. Provide equally effective heating and cooling of the medium. They have a boiler, which, if necessary, raises the temperature of the environment.

Fan coil unit characteristics

The fan coil unit connected to the chiller via a piping system is a type of receiving equipment.It provides not only the receipt of the environment of a given temperature, but also its transfer to the air masses. With the help of a built-in fan, the heating equipment mixes warm and cold streams. All fan coil units are divided into:

- floor;

- wall-mounted;

- ceiling;

- combined (wall-ceiling).

Channel fan coil units are installed inside ventilation shafts (channels), through separate air ducts they take air masses from the atmosphere outside the building. Exhaust gases are removed from the premises by means of pipelines laid hidden behind the structure of the suspended ceiling. Such equipment options have proven themselves well within the framework of application in warehouse complexes, shopping centers.

The cassette indoor units of fan coil units are designed for ceiling mounting, while the air flow can only be directed in 2-4 directions. They are convenient in that they completely mask the working elements of the system.

The noise level in fan coil units built into a suspended ceiling is also significantly lower than in split systems or air conditioners.

Advantages and disadvantages

First of all, it is worth noting the obvious advantages of the chiller-fan coil combination.

- No restrictions on the length of the pipeline network. It is limited only by the capacity of the chiller itself, while the efficiency and productivity of the equipment at the farthest point will be unchanged, as in the entire system.

- Compact dimensions of the equipment. Chillers are most often mounted on the roof of a building without disturbing the harmony of its facade architecture.

- Minimum costs of system deployment. The chiller-fan coil unit uses conventional steel pipes rather than copper pipes, so the total cost of piping is lower.

- High level of security. The system is completely sealed, and since it does not use gaseous substances, the equipment cannot harm the environment and human health even in the event of leaks and accidents.

- Responsiveness. Through the control unit and consoles, users can independently regulate the operation of the system, including in individual rooms.

There are also disadvantages. Compared to gas heating systems, fan coil chillers are more expensive in terms of the cost per unit of energy. In addition, the equipment itself is quite expensive, requires professional installation and inevitably produces significant noise during operation.

Applications

The use of chillers-fan coil units is in demand, first of all, where it is required to create an individual microclimate in rooms of different size and purpose. Accordingly, they can be found in:

- hypermarkets and supermarkets;

- warehouse and industrial complexes;

- hotel, office buildings;

- entertainment centers;

- medical clinics, sanatoriums, and other recreational facilities;

- multi-storey high-rise business centers.

Chiller-fan coil unit makes it possible to regulate climatic parameters inside buildings and structures, regardless of the characteristics of the external environment. The combined capabilities of heating and air conditioning equipment make it easy to switch to space heating or cooling without additional complications and costs.

Subtleties of installation

The installation scheme of the bundle involves the connection of its three main components to each other. The system consists of:

- chiller;

- fan coil;

- hydromodule - a pumping station responsible for the circulation of the medium in the pipeline.

The design of the last element contains shut-off valves: valves, an expansion tank, which makes it possible to compensate for the difference in volumes of heated and cooled media, a hydraulic accumulator and a control unit.

The whole system works and connects according to a certain scheme.

- The chiller cools and maintains the required temperature of the working environment. If it needs to be heated, a built-in boiler is connected to the case.

- The pump transfers liquid of a certain temperature to the pipelines, creating the necessary pressure to move the medium.

- A plumbing pipe run carries out the delivery of the carrier.

- Heat exchangers - fan coil units that look like a tube grid with a liquid circulating inside - receive the medium.

- Fans behind the heat exchanger direct air towards it. The masses are heated or cooled, they enter the room, the exhaust air is removed, the new one is supplied by the supply method.

- The system is controlled by an electronic control unit. With its help, the fan speed is set, the speed of the medium circulation in the system. The remote control can be in every room. In addition, each fan coil unit is equipped with a valve that can be used to switch the system from cold to hot mode, replace or perform preventive maintenance of equipment by shutting off the medium supply.

At the same time, the connection process looks like a definitely related sequence of actions. Manufacturers of chiller-fan coil units recommend exclusively professional commissioning and installation for their systems. But in general, the installation process includes:

- installation of units at locations selected for them;

- formation of the system piping assembly;

- laying a route along which the medium will circulate, installing thermal insulation on pipes;

- arrangement and sound insulation of air ducts;

- formation of a drainage system to remove accumulating condensate from fan coil units;

- summarizing the electrical network connection, laying cables and wiring;

- checking the tightness of all elements;

- commissioning works.

The chiller-fan coil system can only be put into operation after preliminary tests have been carried out.

Service features

When operating the equipment, attention should be paid to routine inspection activities. All elements of the filtration systems must be replaced within the period specified by the manufacturer, the radiators installed in the premises must be checked for corrosion and leaks. Inspection of the main nodes, depending on the scale of the system, is carried out weekly or monthly.

The control panel should be periodically monitored for the accuracy and speed of execution of the commands given. Electrical components are tested for amperage and other characteristics that could indicate a leak or abnormal condition. The voltage on the line and in phases is measured.

Requires maintenance and ventilation equipment. It is cleaned, lubricated, the functionality of the work, the speed of rotation of the shaft are monitored. The drainage system is checked for efficiency in removing moisture. Also, the radiator periodically requires sanitary antibacterial treatment, which makes it possible to exclude the spread and formation of pathogenic microflora.

The optimal temperature regime in rooms where fan coil units are used should not be lower than +10 degrees.

See below for more details.

The comment was sent successfully.