How to choose shoes for a welder?

A welder is one of the professions that involves the use of overalls while working. The outfit includes not only a protective suit, but also a mask, gloves, and shoes. Boots must meet certain standards, and it is also important that they are comfortable. This article will walk you through how to choose shoes for the job.

Peculiarities

Welder's boots are a means of protection, therefore, the requirements for them are appropriate. They must be able to withstand high temperatures, metal splashes, electric current and other industrial factors that a technician may encounter. With this in mind, it becomes clear that ordinary casual shoes are not suitable for such work.

On the market you can find not only specialized, but also universal models.

Manufacturers report that they are designed for different types of production activities. Welders can also choose something from this range, but you need to focus on the specifics of the work and conditions in order to find a suitable option.

Views

Seasonality.

- Winter - suitable for long-term outdoor exposure during the cold season. On average, they are designed for temperatures up to -25 degrees, depending on the model. Equipped with a stable, grooved sole to prevent slipping.

- Insulated - a kind of winter boots. Able to withstand up to -45 degrees. Inside there is a high-quality high-density insulation.

- Summer - equipped with a lining of breathable materials, lighter. They often have a water-repellent surface. Suitable for indoor and outdoor use.

According to the material.

- Leather - the top of such models is most often natural, as this adds durability to them. Outsole made of nitrile or other material that can withstand acids and other chemicals. Leather shoes are summer and winter.

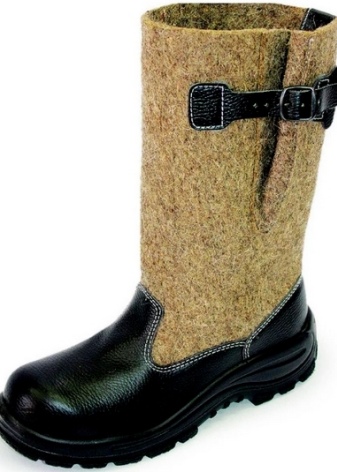

- Felted - designed for the cold season. Felt retains heat well, in such boots you can work at temperatures up to -45 degrees.

You can also single out a separate category - shoes with special properties. These models have characteristics that distinguish them from standard options.

These can be protective flaps, stitching with heat-resistant threads, a non-melting sole, or something else.

Model overview

Shoes are produced by domestic firms: Vostok-Service, Technoavia, TRACT, as well as foreign companies: Delta Plus, Jalas, ESAB. Welding boots or boots can also be found from other manufacturers that specialize in protective equipment.

- Jalas 1868 KING. The upper is made of leather coated with PU for added protection. The sole is rubber. There is an aluminum toe cap. The shoe is suitable for indoor and outdoor use, has good shock absorption properties and allows you to maintain stability even on slippery surfaces.

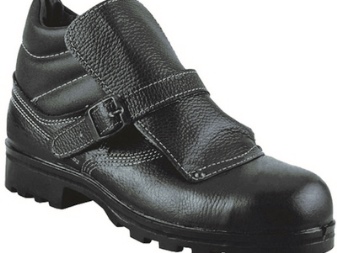

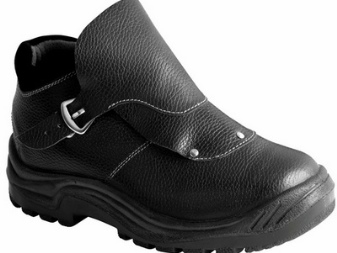

- "Vector-M". Universal boots for work in the agricultural, construction industry, suitable for welders. The metal toe cap protects the foot from impacts. The upper of the product is made of leather, the sole is made of polyurethane with injection molding, which gives additional durability. The cuff has a buckle for adjusting the width. Designed for a temperature range from -20 to +110 degrees.

- "Polar explorer". Felt boots with leather upper.Available with thermoplastic or metal toe cap, the second option is recommended for welders. Foam rubber outsole with excellent slip resistance. Operation at temperatures up to -45 degrees is possible.

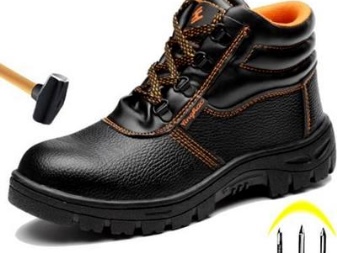

- "Scorpio Welder +". Boots with a top made of genuine leather, there is a valve and a tongue to protect against scales and foreign substances. The nitrile sole has a molded mount, resistant to gasoline, oil substances, acids. The polyurethane intermediate layer provides good cushioning. Metal toe cap protects against impacts.

- "Fast and Furious-S". Boots for the winter period, made of waterproof leather. They are produced with a composite toe cap, which is not inferior to metal in terms of stability. The nitrile outsole has anti-slip properties, withstands the effects of various chemicals. The shoes are equipped with reflective inserts.

Criterias of choice

Shoes or boots must meet the requirements of GOST - this is confirmed by a special certificate that can be asked from the seller.

When buying safety footwear, production factors should also be considered.

- Place of work. In winter, outdoors or in a cold workshop, it is worth using insulated models. If the room is heated, summer or demi-season boots will do.

- Equipment used. For those who often carry large items and heavy tools, it is better to pay attention to models with a metal or composite toe cap.

- Mobility level. If the work involves constant movement around the workshop, then lighter shoes with flexible soles will do.

In addition to operating conditions, you need to pay attention to the characteristics of boots and boots.

- Material. It is advisable to focus on natural leather, a combination with artificial is allowed. For winter time - felt or additional insulation with fur. A special impregnation is required, which protects the shoes from chemicals and high temperatures.

- Toe. Most often it is metallic - this is the best option. A composite one is also suitable - in terms of stability, it is no worse. This detail protects your toes from accidental bumps and bruises.

- Fittings. It is better to choose shoes with laces, as the zipper can stick or get hot. Pay attention to the presence of a protective valve or lining - these elements protect against scale and foreign objects getting inside.

- Sole. Thermopolyurethane can withstand up to 195 degrees with short-term exposure, and nitrile - all 300 degrees. This is reflected in the cost, so it is better to select an option for specific working conditions so as not to overpay. The most reliable method of attaching the sole is injection molding. It will be useful to have an anti-puncture insole for additional protection.

Operation and care

Welding boots and boots require some maintenance. For products to last longer, they need to be cleaned after use, since toxic substances can gradually corrode even stubborn materials. If you do not use shoes for some time, it is better to store them in a dry place, in a separate box or special bag.

During operation, make sure that the selected model is suitable for the working conditions and withstands the influence of various production factors.

Not only the service life of the shoe depends on this, but also your safety.

For detailed information on shoes for a welder, see the video below.

The comment was sent successfully.