Facade mesh for plaster: selection features and installation tips

The attractiveness and durability of the facade are important characteristics for any building. In order to perform a high-quality exterior finish, various materials are used, including plaster, the work with which requires additional products that increase its efficiency and aesthetic qualities. One of these items is the facade mesh for plastering.

Features and purpose

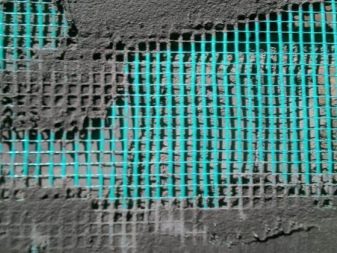

Plastering walls is a construction process, during which plaster mixes of various texture and color can be used. Compositions for outdoor use are produced on an acrylic and silicone base, on the basis of liquid glass or cement, composite mixtures. Each type of product has individual properties and features, but all types of plaster have one nuance in common - the application technology requires a special mesh. It is usually laid between the finishing and the base of the building, in some cases on the heat-insulating material.

The main function of the facade mesh is considered to be the bonding of the plaster composition. It provides additional strength to the solution during its application to large working surfaces, which is important for high-rise buildings.

It is a fairly common practice to use façade meshes when decorating new homes, where the structure is expected to settle. The presence of the facade mesh helps to eliminate the risk of cracks on the wall surface, positively affecting the mechanical strength of the plaster mortar.

But, besides this, the product can be used for other purposes during finishing work - ensuring high-quality adhesion of the reinforced plaster mixture and waterproofing raw materials, for sealing the corners of the structure, for repairing the facade of the building. For each separate type of work, a certain type of product is used that has the necessary qualities and properties.

Facade mesh has recently become ubiquitous along with finishing; a few decades ago, printed shingles made of wood were used to create such a layer. However, the advantages of the mesh allowed it to compete with the fastening of a wooden frame for finishing, so the product began to be used everywhere.

Facade plaster has high aesthetic properties, and is also perfectly combined with various designs, in addition, the composition has a long service life.

The following properties can be attributed to the positive features of the plaster mesh:

- high level of protection of the base from defects;

- reliable bonding of joints of materials;

- the product can be used to work with most finishing materials for finishing;

- the presence of a mesh allows air to circulate freely through the walls;

- some types of products provide an even application of the composition;

- most of the materials are resistant to substances containing alkali, so the mesh does not deform or decompose.

Among the main functional tasks of the facade mesh, it is necessary to highlight the following:

- providing additional thermal insulation;

- reinforcement of bases;

- waterproofing walls;

- protection against deformation of the finish;

- protection of grounds from the impact of negative environmental factors;

- thanks to the cellular structure, the solidity of the adhesion of the plaster composition to the surface is ensured;

- the product increases the service life of the finishing compound.

Views

Based on the main raw materials used for the manufacture of facade mesh for plastering, they are classified as follows:

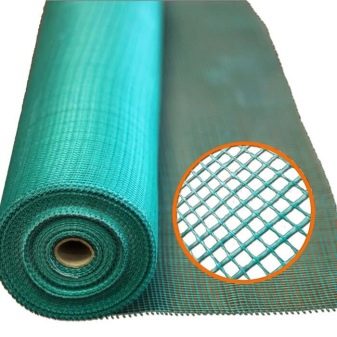

Polymer

In this case, polymers are used as the basis - polyethylene, PVC, nylon. The product cells can have the shape of a rhombus or a square. The most popular products, taking into account the size of the cell, are diamond-shaped nylon products 10x10 mm, 15x15 mm, 50x50 mm, as well as grids with square cells 10x10 mm, 30x30 mm, 40x40 mm, 50x50 mm.

According to experts, the most suitable products for facades are grids with square cells 10x10 mm.

It is worth noting the main advantages of polymer products:

- corrosion resistance;

- due to the minimum mass of products for the installation of the mesh, no reinforcement of the building foundations is required;

- products are sold in rolls, so it is convenient to transport them, in addition, the installation of such a product is facilitated;

- raw materials are absolutely safe for humans;

- polymer mesh has a high level of moisture resistance;

- the product can withstand a five-centimeter layer of plaster.

The disadvantages of products include the following characteristics:

- the products are not resistant to high temperatures;

- products are destroyed by alkali;

- not used for plaster, the application of which requires a layer thickness exceeding 5 cm.

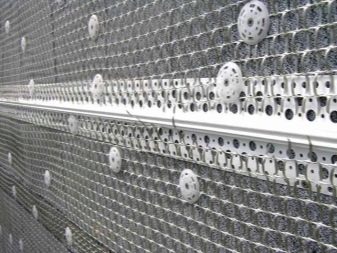

Metallic

During the production of the product, thin rods are used from various types of steel, as well as non-ferrous metal alloys. The latter products are of high cost.

Some manufacturers, in order to increase the quality of their products, additionally process products with special compounds based on polymers, zinc or tin.

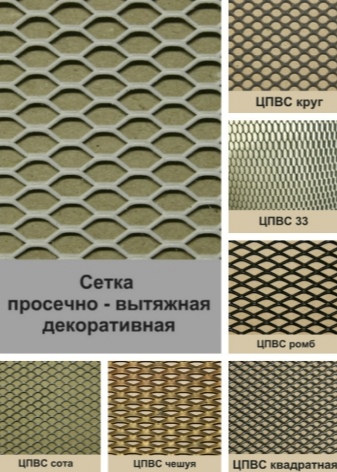

Based on the method of producing metal facade grids, they are divided into the following subspecies:

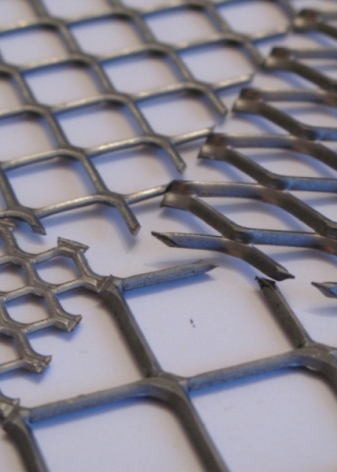

- Expanded metal. The peculiarities of performing work on the manufacture of such products consist in the use of a solid sheet of metal, on which cells of a given size are cut. Such products are necessary for applying the plaster composition to the corners of buildings with complex shapes.

- Rabitz. It consists of spirals intertwined with each other. Products can have additional coverage or be sold without it.

- Welded products... The raw material for manufacturing is fittings, which are connected by welding. Such meshes are light, with a reinforcement diameter of up to 6 mm, and also heavy, where the diameter can reach 40 mm.

For plastering, metal meshes are used in rolls of 2-3 meters with a mesh size of 10x10 mm, 15x15 mm, 20x20 mm.

Advantages of metal products:

- a large indicator of adhesion to the composition;

- the convenience of use;

- products with additional coating are resistant to the influence of aggressive substances.

The disadvantages include the occurrence of corrosion on the product, where the protective layer has been damaged. In addition, the metal mesh is a good current conductor, as a result of which it cannot be installed in close proximity to power grids.

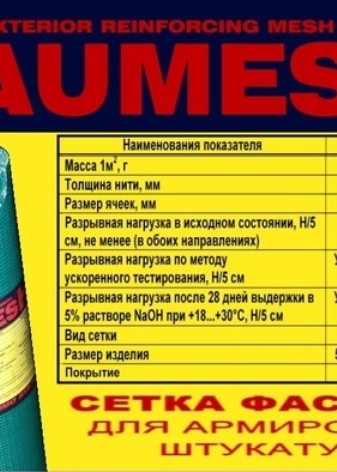

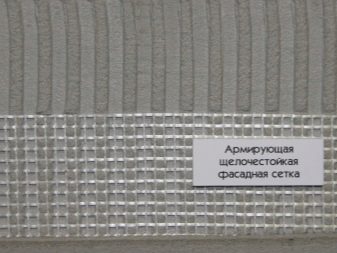

Fiberglass

Fiberglass threads are used for the manufacture of goods. On the market, the mesh is presented in rolls and can be white, gray, black, yellow or other colors.

The density of the product ranges from 145 to 160-165 g / m2, the mesh size of the fiberglass mesh is 5x5 mm.

It is worth noting the main positive features of the product:

- inert to chemicals;

- has a high resistance to temperature fluctuations;

- low weight of products;

- refers to the type of non-combustible product;

- does not conduct current;

- differs in elasticity;

- products are not deformed under the influence of ultraviolet radiation;

- fiberglass mesh is absolutely safe for human health.

During the operation of the products, product defects were not noted.

Application area

All facade plaster meshes are notable for a wide range of applications, in addition to being used in conjunction with plaster mixtures. The following cases should be noted in which the products may be used:

- protective structures are made of mesh, for example, fences;

- the product is used as a covering product during works with facade finishing;

- loggias and balconies are decorated with nets;

- some products are used in the course of filler substrates.

Selection Tips

As the range of facade meshes is constantly being supplemented with new products, it can be difficult to choose the right product. In order to choose the right one or another mesh, it is necessary to pay attention not only to the type of raw material from which it is made, but also to a number of other nuances.

For products made of synthetic materials, as well as for fiberglass nets, the most important characteristic is resistance to aggressive media and strength under mechanical stress. It will be useful to pay attention to weaving - the strength of the product directly depends on its quality.

You can focus on the information that the manufacturer indicates on the packaging. The density of the mesh will indicate the maximum allowable breaking load on the material. For even walls, the value should be at least 1800 N.

How alkali-resistant mesh, manufacturers also usually write on the packaging. But this indicator can be checked independently. To do this, the product is immersed in a soapy solution for several days, after which the mesh is inspected. If it has changed its color and began to disintegrate, it means that the products are of poor quality and cannot be used in work. Special care should be taken with products made in China, and this applies not only to reinforcing and painting nets.

Galvanized metal armor nets have a longer service life compared to uncoated products. Welded products are not always reliable, so it is better to focus on expanded metal products. As for the size of the cells, preference for one or another product should be given based on the specifics of the plaster composition, stages of work and the thickness of the applied layer. Finishing requires the use of a mesh with the smallest mesh; for decorative plaster, you can purchase a fiberglass mesh with an average mesh size. For a plaster layer more than 5 cm thick, it is necessary to give preference to metal products.

General rules for visual assessment of the quality of facade meshes:

- the edges in the roll must be even;

- weaving should be free from defects;

- products with damaged packaging should not be purchased;

- each roll must have a product information label.

Installation rules

Work with a metal mesh is carried out using the following technology:

- first of all, the base is cleaned and all deep defects are removed;

- the walls are measured in height, after which the product is cut to the required size;

- a hole for fastening is drilled from above, the mesh is fixed with self-tapping screws;

- after that, the product is fixed along the entire length;

- the product is wetted and work begins with the plaster solution.

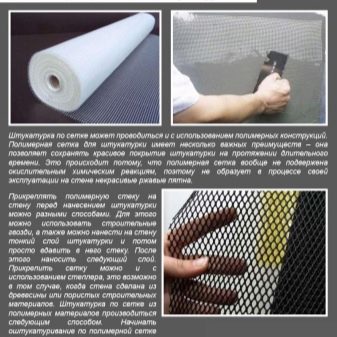

Work with polymer mesh and fiberglass products is performed according to the following scheme:

- cleaning the surface from possible contamination;

- priming and plastering of walls;

- the bases are measured and, based on the obtained values, the necessary pieces of the mesh are cut off;

- application of adhesive - the packaging contains recommendations regarding the consumption of glue;

- then the mesh is applied to the base, using a spatula, the glue is leveled over the entire product;

- after the composition has dried, plastering work is carried out.

Tips & Tricks

In order to perform the external finishing of the building with high quality, you should follow the instructions that will help to avoid the most common mistakes:

- work should be performed only in dry weather with an air humidity of no more than 80% and a temperature exceeding +5 degrees;

- care should be taken to protect the plaster layers from exposure to ultraviolet radiation, precipitation and strong gusts of wind;

- if you plan to purchase a color mixture, you need to buy materials from one batch, made according to GOST and from one manufacturer, in order to avoid inconsistencies in colors and shades;

- there should not be a large distance of 80-90 cm between the base and the thermal insulation, the most optimal would be a distance of about 45 cm.

Situations should be avoided in which even the use of a facade plaster mesh will not help to exclude the formation of defects during plastering of the base:

- In the process of uneven drying of layers of plaster, applied with a layer of different thickness, especially in the corners, a defect of uneven coloring may occur. Therefore, it is necessary to carefully control the thickness of the layer of the composition with which work is carried out over the entire area of the walls.

- Due to mistakes made during the preparatory work with the bases or as a result of their absence, peeling of the plaster composition may occur, regardless of the presence of a mesh. Also, similar situations can arise with a too thick layer of the mixture.

- Conversely, a very thin layer of material will lead to the fact that the existing irregularities on the walls will be visible.

- Even the highest quality and correctly selected grids cannot exclude the occurrence of unpleasant situations associated with the application of gypsum mortar to the walls. In some cases, such plaster peels off over the entire area of the wall. This negative feature is explained by the fact that the composition reacts with moisture from rain, intensive absorption of liquid occurs and the layer of plaster completely lags behind the base.

For information on how to properly mount the facade mesh, see the next video.

The comment was sent successfully.