What is a spatula and what is it like?

In the course of construction work, a spatula is considered one of the indispensable tools. It is used for applying finishing leveling compounds, as well as adhesive solutions. It is a blade with a handle located in a single plane.

What it is?

A construction trowel looks like a plate with a handle made of metal, plastic, rubber, or other material. The tool can have a wide variety of shapes and dimensions. In the construction and repair business, it is used for:

-

grouting brickwork or tiles;

-

elimination of minor defects on laminate and wallpaper;

-

laying tiles;

-

puttying the surface;

-

cement mortar application;

-

cleaning surfaces from old oil paint, putty and wallpaper residues.

For each type of work, separate types of spatulas are used. Some are intended for decorative finishing, others for rough preparation of bases, and others for finishing leveling. The tool should be selected in strict accordance with its purpose, otherwise the quality of work may significantly decrease.

Types by appointment

The parameters of using a spatula directly depend on its shape, density, dimensions and material of manufacture. Let us dwell in more detail on the description of the main modifications of construction spatulas.

Painting

This group of tools is used for finishing horizontal and vertical surfaces. They are relevant when working with putty, plaster and other building mixtures for interior decoration. Tool width varies from 20 to 450 mm. The blade is thin, trapezoidal.

The narrowest models are in demand when processing hard-to-reach areas. For example, when smoothing a building mixture in the space between a window sill and a heating radiator. To prepare the walls, spatulas with a width of 250-350 mm are most often used, such dimensions allow you to evenly apply the building mixture to the surface, covering all irregularities. Along with the main tool, auxiliary products with a width of 150 mm are used for facing the premises. With their help, the building composition is recruited from the container and redistributed along the blade of the main spatula.

Since the blade of a painting trowel is thin, it can bend from mechanical stress. Therefore, in order to create a flat surface, the working edge of the blade must be inserted at a right angle onto the sander.

The most expensive models provide stiffening ribs on the back of the blade in the place where the working surface is attached to the handle. This allows you to minimize the appearance of concavity at the time of force pressure on the spatula.

Facade

The spatula for exterior decoration has a similar structure to the painting one. It is distinguished by its large strength - this is explained by the need to work with plasters and other heavy building compounds. Since the quality of smoothing of facade plastering is usually much less demanding, then the tool for this type of work is made quite wide - this allows you to speed up the process of applying the solution to the maximum. Typically, the grip of such a blade is 300-600 mm.

Often, a facade trowel is used for indoor plastering. This is possible in a situation where the main plane has already been formed and it is only necessary to slightly increase the level of its smoothness. In this case, the width of the spatula will allow a high working speed to be developed.

Corner

Highly specialized types of spatulas are in demand for finishing external and internal corners. Such tools, unlike all other models, have a blade curved at an angle of 90 degrees. Depending on the location of the handle, such a spatula allows the formation of external and internal corners.

An angled spatula is a rather specific tool, when working with it, skill and dexterity are required, so its use cannot guarantee that right angles are obtained. To achieve the desired result, the tool must be guided continuously from top to bottom - only in this case, the angular line turns out to be even. In most cases, this spatula is used when working with internal corners, since the external ones are traditionally reinforced with a perforated corner. It strengthens the plaster angle and greatly reduces the risk of its deformation in the event of mechanical damage.

Scrapers

Such a tool is in wide demand for dismantling. It allows you to scrape off the old layer of plaster and paint before applying a new leveling layer. It is often used to remove frozen masonry particles and wallpaper residues. It is distinguished by a narrow blade - up to 80 mm, it is optimal for cleaning tile joints. The spatula is made of dense, rigid steel, resistant to abrasion. The tool loses its sharpness with use, so it must be sharpened from time to time to optimize performance.

In some models, a metal protrusion is provided on the back of the handle, it allows you to drive in the end of a spatula when removing particularly difficult coatings.

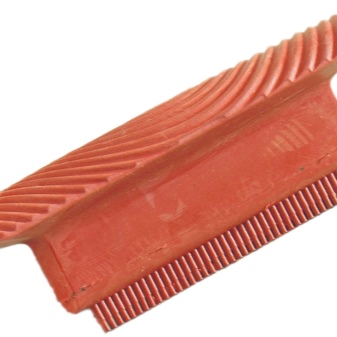

Toothed

Such a spatula is similar to a painting tool, only its edge has triangular, round or square cutouts. The tool is relevant for applying adhesive, it is used when installing ceramic tiles, linoleum, drywall and aerated concrete blocks. The use of a working tool with notches allows the adhesive to be evenly distributed on the surface in the form of parallel stripes. After fixing the adhesive substrates, such stripes instantly spread, minimizing the risk of air voids. In this case, the layer of glue is obtained 2 times narrower than the height of the notches.

Wallpaper

When gluing wallpaper, rubber or plastic spatulas in the form of a wing with one pointed corner are indispensable. They allow you to smooth the wallpaper in places of inflection and near joints. Such a tool does not have a special handle, the grip is made at the places of the thickening on the body.

For work with sealants

Rubber tools are used to remove excess sealants and glue. They are relevant when grouting tiles: the spatula slides over the surface without scratching it. It is in demand when applying sanitary sealants during the installation of kitchen countertops, bathtubs and sinks. Rubber spatulas are useful when gluing aquariums and installing mirror surfaces. Depending on the specific model, the tool can have a comfortable handle made of durable material or be fused, when both the handle and the blade are one piece.

Curly

Curly spatulas with an applicator have found their application in the design of relief on fresh paint or putty. The stone texture and imitation of natural wood are very popular. By applying a spatula to the dry mortar, the pattern is transferred to the surface. Usually such tools are made of rubber and plastic, they can have a very different relief, different sizes and depths.

Other

Slightly less common are spatulas for decorative plaster bark beetle - it can be a Venetian spatula or a trowel. They are not suitable for leveling walls, they are only used for finishing.

Ribbed products are optimal for wood and mosaic decoration. The working surface of such a device has a complex four-sided shape, which is fixed on a rubber or wooden handle.

The Japanese spatula is slightly different from traditional tools, it is very simple and easy to use, although it is used much less often than conventional ones. Such a spatula looks like a rectangular plate, in which a handle-profile is attached to one side along its entire length. This tool is sold in sets of 4 (with blade widths 60, 80, 100 and 120 mm). The most popular in the construction industry are models of 100 and 120 mm, they have a strong elastic blade that does not lose its functionality when bent.

Japanese spatulas are in demand when processing complex structures with convex and concave bases, when installing arches. They are relevant in situations where it is required to apply the thinnest layer of putty.

On sale you can find universal models. It is a multifunctional tool that allows you to perform a wide range of jobs. It is suitable for the application of mortars and as a jointing tool.

When choosing a spatula, special attention should be paid to its size. The blade width must be suitable for a certain type of blade, otherwise the quality of work will decrease.

Dimensions (edit)

The widest dimensions are for facade finishing tools. Their width is 600-800 mm, this significantly increases the area of the processed surface in one pass and allows you to eliminate the most serious surface defects in the shortest possible time. Typically, such devices are applied in a thick layer. The wide category also includes spatulas with a blade of 300-400 cm, which are optimal for processing ceilings and interior walls of a room.

Medium-sized tools have a blade width of 150-250 mm. They are in demand when eliminating surface irregularities, dents and other defects left after rough processing of walls and ceilings. After using such a tool, the putty layer becomes smooth. It is allowed to have minimal defects, which are quickly corrected with sandpaper.

With a narrow spatula 50-100 cm wide, they eliminate the smallest cracks and depressions. For larger defects, they are unsuitable, since they begin to repeat their outlines and leave all the irregularities in the same place. These tools are ideal for picking up spray liquid from large containers and for lining narrow areas.

Manufacturing materials

The performance of the spatula directly depends on the material from which they are made. For the production of this construction tool, plastic, rubber, aluminum or steel are usually used. Metal spatulas are the most common modification. They are in demand when working with building compounds of all types, including putty, tile adhesive or Venetian plaster.

Plastic models are characterized by elasticity and plasticity, so they are indispensable, if necessary, to apply a building mixture in a thin layer. In addition, they are used to gently smooth surfaces. That is why they are used for gluing wallpaper, applying assembly adhesive solutions and liquid wallpaper. In the course of work, they wear out, therefore, after each serious use, they should be replaced.

Rubber spatulas have the most effective elasticity parameters. They have the property of sagging under the parameters of the relief along which the solution is led. They are mainly used to remove glue and sealant protruding onto the facing surface. Spatulas made of silicone materials can have different degrees of rigidity, some models correspond in strength to plastic counterparts.

The handle of any construction trowel can be plastic, as well as wood or aluminum. It can be placed in the same plane with the work surface or connected at right angles. Its location directly affects the features of the operation of the tool.

Manufacturers

Nowadays, shops offer a wide range of spatulas of different manufacturers, sizes, materials of manufacture and price category. Among the construction devices for applying the mixture, you can find products of foreign and Russian brands. If you need a tool for performing one-time work, you can choose cheap models of Chinese and Korean production. If you need the tool on a regular basis, then you should give preference to professional products. They are more expensive, but made from the highest quality materials. The best user reviews were received by the models of firms:

-

Homa;

-

Eurotex;

-

Santool;

-

Matrix;

-

"Bison";

-

Intek.

These manufacturers ensure consistently high quality of their products and provide a long-term guarantee for their use. The price of imported products, as a rule, is an order of magnitude higher than the cost of domestic ones.

Selection Tips

When buying a spatula, you need to adhere to the recommendations of specialists.

To choose a good spatula, you first need to assess the degree of comfort in the hand and the quality of the handle. A plastic handle can be easier to clean from building mixtures, but it is more fragile than a dense rubber one. Handles made of wood have proven themselves well, as well as products in which the front part is rubberized. Such tools never slip out of hand, thereby facilitating finishing work.

Keep in mind: Handles that are too narrow and too long are inconvenient to use.

Special attention should be paid to the thickness of the blade. For medium and wide spatulas, it should be at least 0.5 mm, otherwise the tool will begin to bend and deform even with a minimum load. The more work you have to do, the thicker and stronger the spatula should be.

Trapezoidal spatulas are considered the most convenient and effective. Tools in the form of droplets and triangles are inconvenient to use; professionals use them extremely rarely.

Be sure to test the spatula - in the working part it should spring slightly.

Stainless steel models are considered ideal. Ordinary iron products, as they are used, begin to rust from constant contact with a wet solution. A quality product should not have burrs and grooves, otherwise it will leave an uneven mark when processing walls and ceilings.

Care features

All types of spatulas are used to apply quick-setting mortars - glue and plaster. That's why from time to time, the tool must be rinsed with water, otherwise the soiled product will dry out and it will be very difficult to remove dirt from the surface. Therefore, after each use, the spatula must be thoroughly washed and wiped dry.

You can try to wash off indelible layers using a concentrated solution of acetic or citric acid. To do this, they dissolve in boiling water, a spatula is dipped into the resulting solution and left there for 24 hours. This time is enough for the acid to soften cement and gypsum compounds. Such a tool can be easily cleaned with a sponge until it is completely clean.

Prolonged boiling in plain water also gives a good effect.

It happens that new trowels with a flat steel blade begin to leave furrows on the surface during operation. This defect can be eliminated in two ways.

In the first case, a slight bend of the blade is required. To do this, its pointed edges are slightly bent to one side, as a result of these manipulations, the reverse part of the blade can be used as a working surface.When using a bent trowel, no stripes remain at the edges.

The second way is more efficient. It involves sharpening the sharp edges of the tool. They become radial and do not damage the surface.

The spatula is an indispensable construction tool that is used at most stages of repair and finishing work. It is extremely difficult to carry out construction work in proper quality without it. But one of the main requirements for ensuring the functionality of the spatula is proper care of it.

Do not bend it, expose it to excessive loads, or use it for other purposes. Treat him with care, and then he will serve you for many years and never lead.

The comment was sent successfully.